Swiss printing-technology giant Gallus unveiled details of two of its recent Gallus One customer installations: part of an extensive list of sales across a strong business year in 2024. Both Flexon from the Czech Republic and Yeloprint from Hungary have seen significant success within just a few months of installation, with the presses already demonstrating promise of achieving ROI and breakeven within an impressive timeframe.

The latest to share their successes with the Gallus One, Flexon and Yeloprint join a growing roster of satisfied customers and successful installations since the machine’s launch in 2022. Earlier last year, PrintFlex (US) revealed how the Gallus One had reduced production costs, with CEO Liz Pecha-Poelker explaining that the team were “thrilled” with the investment which offered them “the lowest total cost of ownership [TCO] for digital-label production.”

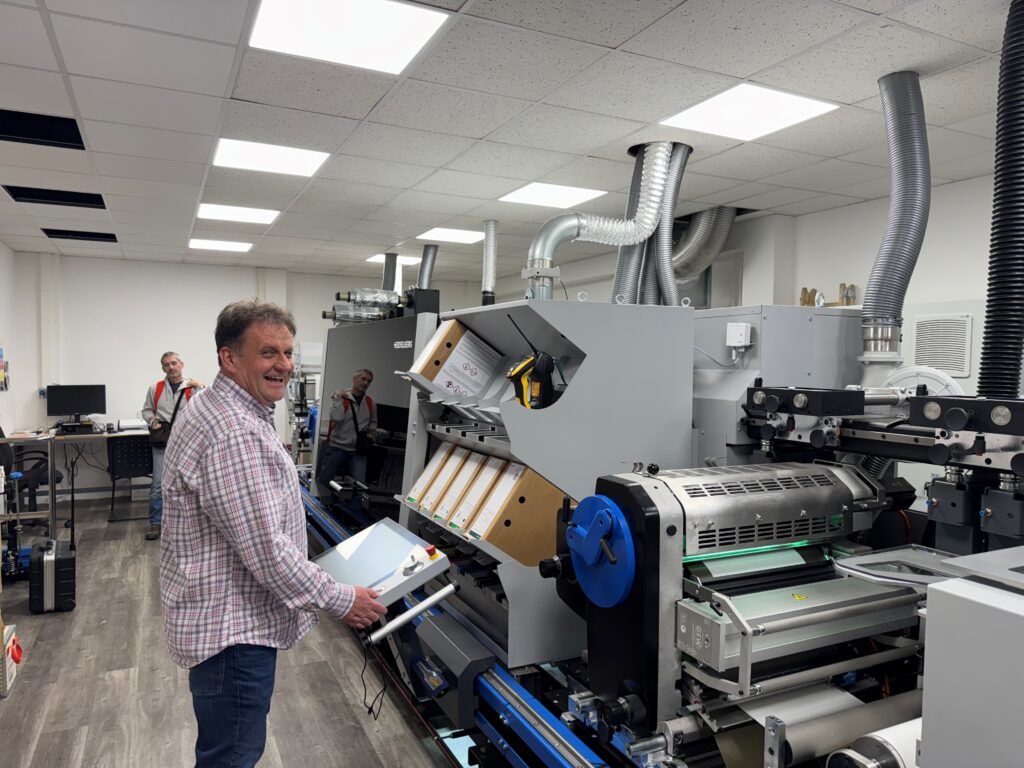

With an existing Gallus Labelfire 340 and a positive experience of Gallus customer service, Flexon, based in Vestec, Czech Republic, installed the Gallus One in November 2024. Already printing commercial jobs within the operator training period, the company claims to have installed the new state-of-the-art digital label press – which it chose with an additional flexo unit and a semi-rotary die cutting module – to accelerate job changeover times for increasingly shorter label runs.

Streamlining production and boosting profitability

Martin Chaluš, owner-Flexon, (above) says, “Given increasingly shorter orders and frequent changes in artwork, the importance of digital printing is growing, which is why we looked at installing a digital label press. Importantly, the custom composition of this new solution means that we now have a finished label that ‘falls out’ of the press needing only to be cut, saving us time, streamlining production and increasing profitability, and the Gallus One has now replaced up to two of our conventional presses. As a previous enemy of digital technology, if someone had told me that I would have two powerful digital machines by 2024, I wouldn’t have believed it. But today, it’s clear that smart, connected printing is key. Anyone who wants to stay in the market will need an appropriate combination of both digital and conventional technologies, it’s just a matter of proportion.”

Yeloprint of Szombathely, Hungary, installed a Gallus One in October 2024, also including two flexo units and a semi-rotary diecutting unit. The company was looking to diversify its technology offering to provide faster, short and medium-length label jobs. Thanks to its successful experience with its Gallus TCS 250, the Gallus One was Yeloprint’s obvious choice – with the press offering one of the lowest TCOs on the market, as well the speed and print quality it was looking for.

“We needed additional capabilities to meet changing customer expectations for shorter runs, but didn’t want to invest in a large flexo machine. A digital press was the logical step,” comments Dávid Péter, owner-Yeloprint (above). “We chose the Gallus One because of its speed, quality, and its web transport system, with our previous Gallus systems providing a critical confidence in their solutions. Already, the Gallus One is our leading technology, and we calculate a return on investment within only two to three years.”