By Mark Miller, CEO, Coating Tech Slot Dies LLC

Editor’s Note: Part 1 of this technical paper covered different aspects of tensioned-web over slot-die coating, such as elasto-hydrodynamic action, controlling parameters and the three most common variables of TWOSD: indent, span and tension.

Process & design

In addition to the standard variables to be adjusted, physical changes to the slot die or process variation may lead to an improved product. Decreasing the span seemed to help performance, so alternatively you could decrease web speed or reduce the downstream land length.

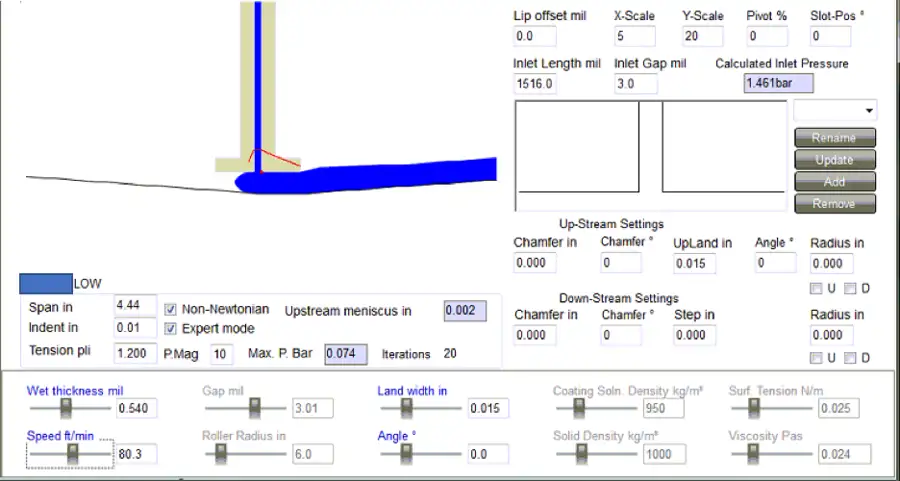

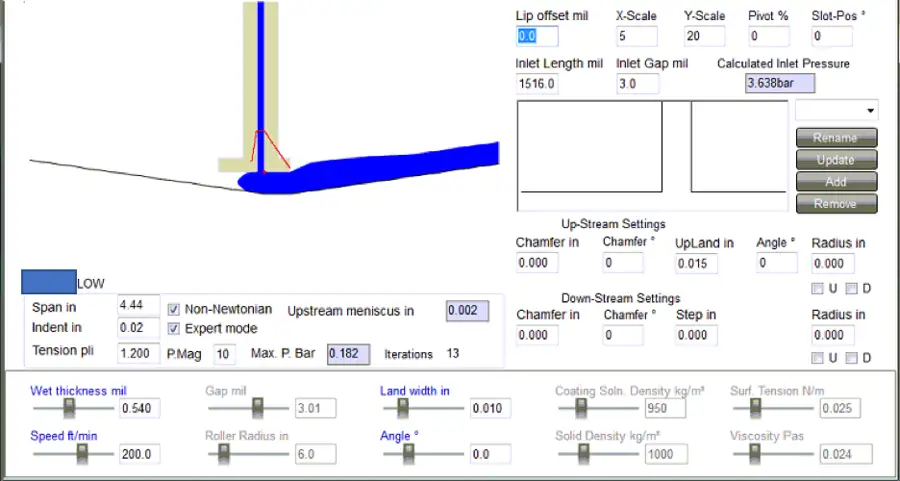

Running at a reduced line speed allowed for reduced indent (see Figure 7). Reducing the down-web lip face (to 0.010 in. from 0.015 in.) allowed for increased line speed (see Figure 8).

Lip-face geometry has been studied in academia and shown that not only the reduced lip-face geometry, but also more curvature in the lip face, can contribute to improved coating capability. The wide variety of lip geometries was not studied here, but in general, more curvature can provide a larger coating window. This lip-geometry variation is very fluid and process-dependent, so it would be recommended to experiment with lip geometries as part of an overall experimental design prior to production.

TWOSD web handling is paramount

In addition to line speed and lip face variations, web handling needs to be paramount when running TWOSD coating technique. Skew between idler rolls is more important and, if the web tends to wrinkle, curl or otherwise travel, the isolation of the coating station takes on more importance.

Unfortunately, the simulation software can place the slot die only at the middle of the span and cannot show the effect of shifting the slot die toward one roller or another.

Standard warnings in TopCoat:

- Ribbing = Pressure(Land Length) > Pressure(Land Length-1) > Pressure(Land Length-2)

- Unstable Flow = Inlet Gap – Upstream Meniscus < 0.2

- Upstream Overspill = Inlet Gap + Land Length – Upstream Meniscus < 0.1

Whether flow instabilities represent a real-world defect witnessed at a current coating arrangement is outside the capability of TopCoat – a coating defect is not recognized in the standard arrangement. If a coating defect were recognized, this warning may point to a change being required either in the process parameters or the slot-die system geometry. Keep in mind that TopCoat software uses math and physics modules. Real-world data may differ, especially for fluids that show more elastic characteristics and non-uniform substrates that can ride the fluid differently than expected.

Key process factors

TopCoat shows the cross-sectional plane of a pump-fed, tensioned-web slot coater. This is a variation of traditional slot-die coating in proximity of a precision backing roll. As with traditional slot coating, the coating thickness is set by the pump feed rate and the web speed. Everything else develops the coating window. Some key factors to consider include the following:

1. The upstream meniscus is comfortably within the upstream lip. If it is too close to the inlet, then transverse barring will occur. If the upstream meniscus overflows the upstream end, then there will be flow beyond the physical pinning of the slot die.

2. Pressure should be in a reasonable range of a couple bar (approximately 30 PSI). This pressure is smaller than with conventional slot-die coating over roll. This is because the web increases the local gap and decreases the pressure, and because the effective pressure from the web is very small for small wrap angles. If the pressure dips into a negative zone on the downstream end of the slot die, this would predict ribbing defect (but does not show as such on the TWOSD module). During these phenomena, the slot die and the web flow are fighting the countereffects of Couette and Poiseuille flow. Couette flow is driven by the moving web, and the Poiseuille flow is driven from the need to move the liquid through the narrow gap. From these, a pressure distribution is calculated, assuming that the film is flat and at a distance from the slot equal to the wet coating thickness. The pressure produced in the slot, then deforms the substrate. Because the gap between the substrate and the slot will have increased, the pressure will have decreased. So when the substrate deformation is recalculated, it will not be as large as before. After a number of iterations, the deformation will stabilize, and the final simulation values are shown.

3. For a specific coating thickness, web speed and rheology, three process variables control the coating window:

a. Span – the distance between the supporting rollers

b. Indent – the amount the slot pushes into the substrate

c. Tension – the amount of tension on the substrate

Span and indent are interrelated. A large span is equivalent to a small indent and vice versa. The important parameter in the slot die is the amount of tension normal to the substrate. The normal tension = tension * sin (angle). Angle = arctan (indent/span/2).

4. Elastic behavior of the substrate is ignored in TopCoat. The modulus and thickness of the substrate are not used in the calculations. The extra force exerted by the substrate on the liquid arises from local curvature of the substrate.

5. The number of iterations of the simulation is a guide to the boundary conditions of the process point. If the number of iterations is high (>200), then the slot die is near a borderline regime of the fluid flow. If the iterations exceed 300, then the simulation assumes no solution is possible.

6. Viscosity and speed are much more significant in TWOSD than conventional slot-die coating. Increasing viscosity and speed increases the pressure in the downstream portion and increases the curvature of the web, and the gap increases. To bring the system under control, the options are to increase tension, increase indent / decrease span or decrease web speed. If these process parameters are not acceptable, then the slot-die downstream land length can be reduced. For low-viscosity fluids at low speeds, the tension should be decreased, indent decreased/increased span or increase slot-die downstream land length.

7. Pressure distribution within the slot die also is important. A modest back pressure is an advantage for leveling out pressure fluctuations in the delivery of the liquid. If the slot lip lengths are small, then pressure control is more critical. Under these circumstances, surface-tension forces are more important than viscous forces.

8. Tension control is helpful because using this process parameter for coating control eliminates the need for accurate gaps. However, using tension control requires accurate control of the tension with little variation during operation of the substrate. This includes controlling the upstream and downstream rollers. Alignment of these rollers becomes important for good control of the tension in this arrangement.

9. Roller setting vs. angle: In TopCoat, the roller settings are not adjustable. The effective angle adjustment is used as a replacement for this function.

10. Lip offset moves the upstream lip relative to the downstream lip, where a positive value increases the gap between the upstream lip and the roller.

11. Inlet gap is the lip-to-lip gap through which the liquid travels to exit the slot die. Decreasing the inlet gap increases back pressure and evens out the flow within the manifold of the slot die. The effect of the inlet gap has a cubic effect on fluid flow. However, with a smaller inlet gap, the precision of the lip surfaces becomes more important and coating lines more apparent.

12. Inlet length is the path length through which the liquid travels before exiting the slot die. The longer the path, the greater the back pressure. Inlet gap has a stronger effect on pressure and fluid flow than inlet length.

13. Pivot% sets the pivot point in TopCoat for the downstream land. The default is to have the pivot at the downstream end of the land. This is the best position for considering the intrinsic science of slot-die coating. However, the setup for an individual process may vary greatly from this arrangement – most slot-die manufacturers tend to define the pivot as 0% (right at the top of the downstream lip). This is a critical component to the outcome of the simulation, with a small variation having a large effect.

14. Length is a term in TopCoat defined as the length of the upstream land independent of the downstream land.

15. Inlet pressure is the calculated pressure needed to pump the required fluid through the slot die for deposition. The goal is to have a small differential between the inlet pressure and the maximum pressure calculated between the lips and the web. Balancing these pressures will ensure a proper fluid balance and a larger coating window.

Conclusion

While there is a lot to take into account when reviewing slot-die coating with TWOSD coating technique, the resulting system can allow for thinner coating thicknesses and improved operability. Keep in mind that all slot-die coating techniques are premetered, so the thickness of the coating is controlled exclusively by the pump rate and line speed. The slot die is simply the vehicle to precision coating. Also remember that a vacuum system cannot be employed to assist in coating because there is not both a roll and a slot die to pin against. These differences are not drawbacks but simply variations in precision coating. Embrace TWOSD and let the physics of elasto-hydrodynamic interactions be your friend and help you coat thinner, faster and more effectively.

Mark Miller, CEO of Coating Tech Slot Dies LLC (Eau Claire, WI), holds a Bachelor’s degree in Chemical Engineering from the University of Wisconsin-Madison, a Master’s degree in Polymer Science and Technology from Lehigh University, and a J.D. from Hamline Mitchell School of Law. He has worked at 3M Co. and Coating Tech Slot Dies, and is affiliated with AIMCAL. Miller can be reached at 715-544-7568, mobile: 715-456-9545, mark.miller@slotdies.com, www.slotdies.com.