By Anye Chifen, Ph.D., senior technical executive, ENGICCS GmbH; and Eiichi Sasaki, Takayoshi Hirono, Kousuke Higashide and Wang Wei, ULVAC

Editor’s Note: This technical article won the Best Paper Award for Vacuum Coating & Patterning at the premiere AIMCAL R2R Conference Asia, held in Daejon, South Korea, in May 2019. That event was co-organized by the Korea Research Institute of Chemical Technology (KRICT).

Summary

Ultra-Thin Polymer Film (UTPF) is used in a wide range of applications where its smaller physical size – as compared to other filmic material capacitors – makes it ideal for miniaturization of devices such as handheld electronics and wearables, etc. It is believed that further miniaturization, higher temperature and better performance will be required on the power film capacitors.

The selection of the film is extremely important to achieve the required voltage and current-carrying capability for high-end applications, such as for DC-link capacitors. The capacitor manufacturer can use various combinations of dielectric materials and terminations in the construction of each type of capacitor. However, the size and weight of the polymeric material are important for the function of the capacitance. The majority of film suppliers have been striving and stretching the limits of film thickness and width by downgauging the dielectric material. Thus, the processability of the materials should be guaranteed in the vacuum roll-to-roll (R2R) metallization process to achieve high metallic purity, specific zonal (bi)-metal distribution profiles, highly defined non-metallized patterns and defect-free deposition.

UTPF has been metallized for the production of high-end capacitors using the ULVAC 1,100-mm-wide web machine, especially for applications whereby DC-link capacitors are indispensable. This report focuses on ULVAC’s solution for UTPF technical trends, process challenges and advancements for the production of complex electrodes.

Introduction

The main effect of a capacitor is capacitance. Capacitance is the amount of electrically charged carriers a capacitor can store per unit of voltage (DESH [1], CHIF [2]). There mainly are two types of capacitors used in the power electronics systems: aluminum electrolytic and metallized-film capacitors.

This report concentrates on the latter type of capacitor, whose characteristics and application are strongly affected by the dielectric (polymer film material) used. As well investigated and reported (DESH [3]), the health of such capacitors depends on external factors such as temperature and humidity, which are solely dependent on the dielectric material. Comparatively, the characteristics of the dielectric material – such as dielectric constant, temperature coefficient, humidity coefficient and dielectric-absorption properties – also are thickness-dependent. Thus, this paper highlights the industrial state-of-the-art processes used to metallize the thinnest dielectric material for the production of a metallized-film capacitor as such to improve the capacitance for solid-state electronic applications.

Metallized-film capacitors

Metallizing or deposition of a very thin layer of aluminum under defined vacuum conditions onto plastic films offers distinctive functional properties (SIEG [4]). Specifically, for capacitor functionality, the electrodes consist of very thin layers < 10 to 100 nm of metal (aluminum Al, zinc Zn and/or silver Ag) vacuum deposited onto the surface of the polymer. The comparison of the different polymer materials used and field of applications is out of the scope of this paper, but it is important to mention that polypropylene (PP), polyethylene terephthalate (PET), polyethylene naphthalene (PEN) and polyphenylene sulfide (PES) are all being used as dielectric materials (ACTA [5]).

Despite the advantages of using any of these materials with respect to PP, their loss factor could be up to 10 times larger (which would yield temperature increments) as compared to PP with excellent electrical properties. Understanding that a capacitor is basically an electrochemical device, a temperature increase would accelerate the chemical-reaction rates (according to the Arrhenius law). Thus, for applications with a stable level of capacitance required, the temperature and frequency dependencies of electrical parameters – as well as hygroscopicity (humidity absorption) for PP film – is of utmost importance to further tailor the thickness of the dielectric property for capacitor applications.

Ultra-thin polymer film for capacitor application

More energy in less volume: This is a unique point for any electronic appliance or device being sold in the market today for applications such as (de-) coupling, filtering, timing and wave-shaping.

The volume of film capacitor almost is proportional to the square of the thickness of dielectric material. The future and new applications are desired for high rated voltage, high capacitance per volume – thus thinner dielectric films (miniaturization) is the goal. This goal cannot be achieved if the required equipment and process handling are not considered during the metallization process. Rubycon, Japan (RUBJP [6]) research reported in 2011 indicated the importance of reducing film thickness and not neglecting the safety pattern of the metallized area and the metallization resistance. UTPF is defined in this report as thickness < 1.90 µm for PP films.

Deposition of Al, Zn, Ag on UTPF: Technical notes to tailor high capacitance

The realization of this process consists of these highlighted counteractions, high-speed winding of ultra-thin film, heating / cooling and segmental printing under vacuum conditions.

This ULVAC system is a high-vacuum, R2R-coating system to deposit a thin film of metal onto one side on flexible plastic webs by thermal evaporation. Vacuum is created using an advanced, proprietary vacuum-pumping configuration with mechanical, diffusion pumps and cryogenic systems in both winding and coating sections. There is an automatic process-control system, whereas the deposition of Al, Al/Zn, Al/Zn-reinforced zone or Ag/Zn layers also are configured for high-resolution segmented or patterned structures at process speeds up to 1,000 mpm.

The following major aspects have been identified for the metallization of thin film to explore the UTPF technical trends and advancements for the production of complex electrodes.

Unique deposition process steps: The processability to combine the different designs of segmented capacitor film with diverse metal profiles (constant, heavy-edges, wide/profile heavy edges and specific heavy edge / active area) at production speed to achieve high-end performance films and productivity is the core of the system design.

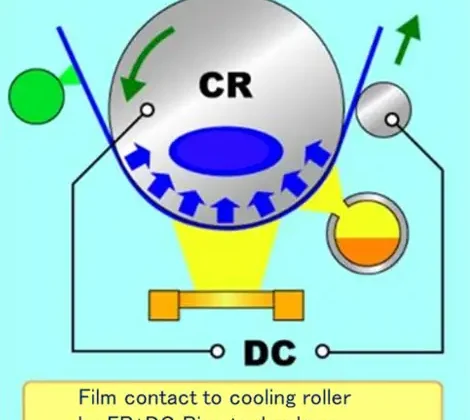

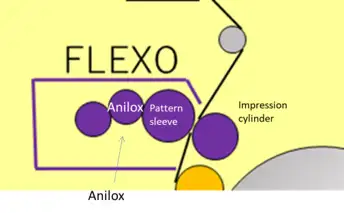

a. Capacitor films where the metallized plane is interrupted by defined lines / structures are well known as segmented or safety films. This segmentation is achieved by an in-line, oil-masking system during metallization. The precision of the segmentation can be credited to the configuration and system design of the oil-evaporation system and the anilox roll aligned with the flexographic roll onto an independent, back-impression cylinder. The segmentation profile accuracy is engineered based on process oil temperature and pressure subjected onto the impression roll. Understanding the importance of general machine system pressure, combined with the temperature feedback so as to achieve less oil consumption and precise segments (electrode space, fuse), contributes to the advancement of achieving higher capacitance with safety on ultra-thin polymer film (see Figure 1).

b. Productivity and performance at 1,100-mm web width: Historically, the web width has evolved from < 650 mm, through 840 mm, 920 mm and up to 1,100 mm. This is driven mainly by the primary BOPP-film production line, which is trimmed for maximum productivity. Concretely, the widest metallizing machines for capacitor applications available today (EWE 1100) are equipped with high-rate evaporation conditions (number and distance in-between evaporation boats), which renders to achieve specific profiles, high-ohmic and equivalent uniformities at desired capacitances. More so, the challenges are still dependent on the base film and process winding steps.

The control of these UTPF materials can be critical, based on the industry knowledge: “not all polymer films are the same.” This holds true especially for properties at low thickness, strain, thickness profile, frictional properties, surface roughness and elasticity. All these aspects are considered during the metallization process. ULVAC’s winding system is further equipped with automated multiple-motor drives, which facilitate the tension control on each contact of the film on a roll. Examining the roller design by considering the individual diameter, alignment and deflection angle as criteria, this would optimize the traction, nipping, guiding and even buckling at high speed for such UTPFs.

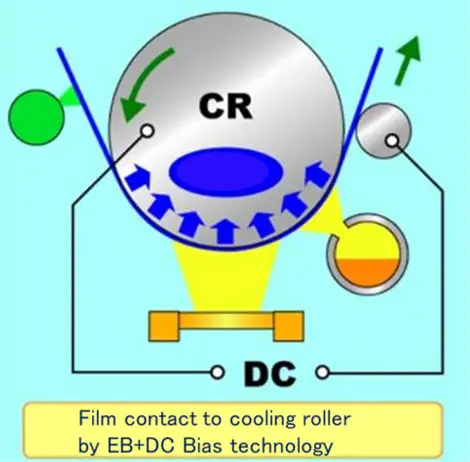

c. Surface charging – cooling & heating efficiency: Surface induction of charges to yield adequate contact between coating drum and polymer film has been optimized by bombardment with a high-energy electron beam (see Figure 2). The electrons trapped in the material induce a highly charged electric field which increases the surface potential. The induced charge enhances the heat transfer and cooling of the UTPF-metallization step. The intensity / power of the charge dissipation is critical for charging the film; however, understanding the primary beam energy and distance to target material would enable the wide deflection of the beam and also process stability at the vacuum conditions.

Post to the surface charging, the metallized-polymer film is bombarded on both sides with defined plasma concentration to neutralize the static / mobile charges induced by the EB / DC bias technology.

Advancement and outlook – ultra-thin polymer film

The drive for capacitive energy storage is centered on developing high-performance film dielectrics. Alternative-metal, metal-oxide and alloy materials always will be considered for higher voltage; however, the miniaturization, stability at higher temperature and better performance of the dielectric material remain the cornerstone for future development. Additionally, improvement of process control of the individual process units, creating defined non-metallized zones and recognizing precise pattern segments are considered inevitable to achieve superb-power film capacitors.

The advancement in terms of productivity aims to achieve up to 1,600-mm-wide web films, which would replace the 650 mm and 920 mm at existing production sites.

References

- R.P. Despande, Capicators, ISBN: 9780071848565

- https://www.idtechex.com/de/event-presentation/major-process-steps-to-improve-the-performance-of-metalized-capacitor-films/3910

- R.P. Despande, Capacitors, ISBN: 9780071848565

- Acta Polytechnica, Vol. 47 No. 1/2007

- IEEE Transactions on Dielectrics and Electrical Insulation 21(2):582-593, April 2014

- http://www.rubycon.co.jp/en/profile/production.html

Anye Chifen is senior technical executive-Vacuum Coating Processes for ULVAC, Inc. He holds a Master’s degree in Chemical Engineering from the Technical University of Dortmund (Germany) and a Ph.D. in Plasma Material Engineering from Max-Planck University (Germany and the UK). Chifen held diverse positions for over 12 years in various polymer thin-film converting companies and machinery manufacturers. He is the co-founder and managing director of ENGICCS GmbH, which focuses on engineering and business development for the vacuum thin-film industry. Chifen can be reached at +49-89-960-9090, email: contact@engiccs.com, www.ulvac.com.