By Eldridge M. Mount, Ph.D., president, EMMOUNT Technologies

Flexible packaging has been evolving since it was first introduced. Today, due to the continuing development of new and existing polymer materials, there are many sophisticated, Fit-For-Use flexible-packaging materials available to the industry, which are used for an ever-expanding number of applications based on the combination of multiple polymers and materials. Today, in the packaging industry, there is emerging the desire for single-polymer packaging products to help simplify recycling of used materials. This article will explore the pros and cons of single-polymer packaging materials in end-use applications and their possible impact on the ease of recycling of flexible-packaging materials.

Introduction

Since the introduction of polymer-based packaging films, they have evolved into highly effective systems that offered extended product protection and have improved the safety, quality and distribution of raw and processed foods. Due to the wide range of product marketing messages and protections desired from vermin, insects, light, moisture, oxygen and chemicals, they have evolved into relatively complex combinations of polymers, metals and inks. These packaging materials have replaced older, heavier products, significantly reducing packaging weight, distribution cost, life cycle energy cost and environmental impact.

I understand that today, in the packaging industry, the desire for a single-polymer packaging product to help simplify the recycling of used packaging materials is emerging. My first thought is, “What do you want, a packaging material that offers great product protection and is fit for use, or one that is easy to throw away?” Part of this skepticism comes from my long-held belief that the best last use of plastic packaging is incineration to recover its energy content. This belief comes in large part from my understanding of the construction and composition of effective plastics packaging, the inherent chemical incompatibility of different polymers and the difficulty in recovering plastic packaging for reuse back into packaging vs. into truck-bed liners, flowerpots, park benches and the like (see sidebar).

This doesn’t mean that I would simply discount the desire for single-polymer packaging but that I would contemplate what it means, contemplate how to come closer to it and understand the limitations it would impose on plastic packaging and the infrastructure of machines used to produce and form packages. This is similar to the current COVID-19 world of “listen to the science” to determine what might be doable based on current understanding of what is necessary and whether it is an improvement for society as a whole.

What’s necessary?

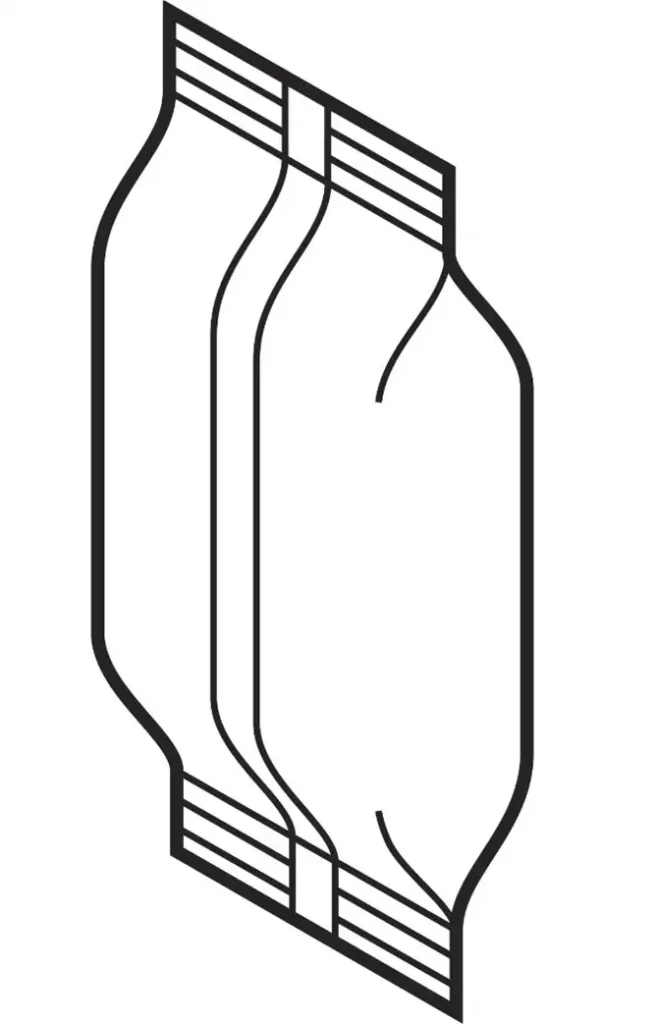

Let’s get started by taking a look on the most basic aspect of current package formation from flexible-packaging materials. In almost all instances, the packaging materials arrive at the packaging machine in a flat, multilayer, printed and laminated roll, which is formed into a sleeve on a variety of packaging machines. The sleeve generally is lap or fin heat-sealed along the back of the sleeve and then sealed at each end as the packaging encases the product (see Figure 1).

Because most existing packaging machines form a heat-seal by heating from the outside surface, to accomplish this most basic aspect of heat-sealing, the inside surface of the packaging materials must have a lower melting point than the outermost portions of the packaging materials (see Figure 2). An alternative is to have a pressure-sensitive adhesive pattern-printed on the packaging lamination. To have a lower melting point, the inside layer must be a chemically different material than the outer layers. “So, what?” you might say. “What does this mean for recycling back into packaging? We will just melt them all together!”

But the difficulty of combining polymers back together is that, with only a few limited exceptions, polymers are chemically incompatible, i.e., they will not dissolve into each other or alloy to make a new material with new properties. They only can be mixed or dispersed, kind of like rice and wheat, each polymer phase retaining the distinct properties of each of the starting polymers. You can grind them together, to make each particle smaller, but they will remain chemically distinct. So, considering the basic packaging polymers of polypropylene homopolymer and copolymers, polyethylene homopolymer and copolymers, polyvinyl alcohol, EVOH, polyester homopolymer and copolymers, Nylon, polystyrene, EPDM rubbers, polyvinyl chloride, Saran and many, many others (and don’t get me started on inks and laminating adhesives), none of them form compatible blends between any of them – only dispersions.

So, what’s possible?

Because of the need for different melting-point surfaces to form flat heat-seals with most existing packaging machines, it practically is impossible to have a truly single-polymer packaging film. Ultrasonic sealing could produce flat, single-polymer seals, but impulse sealing with a cutoff wire is used predominantly for sealing existing single-polymer films, as for magazine dust covers. This creates a relatively weak seal that is not hermetic and easily opened.

So, perhaps the best we can do is to look at single-polymer families to produce simpler-to-recycle packaging. This would take the form of using a single homopolymer and the various copolymers of a polymer class, i.e., polypropylene combines with ethylene-propylene copolymer, butylene-propylene copolymer, ethylene-butylene-propylene copolymers and potentially other comonomer combinations. Similarly, this could be done by combining homopolymer high-density polyethylene with low-density polyethylene, along with the many ethylene copolymers found in the linear low-density polyethylenes. More limited combinations also can be made with crystalline and amorphous polyesters and perhaps Nylon combinations. All of these materials can and are available as cast and mono or biaxially oriented into films to significantly improve strength and durability and to enhance barrier properties of the cast films.

But the loss of coextruding various polymer families together, as is routine today, will result in significant deterioration in critical film properties for both strength and durability; moisture, oxygen, flavor and aroma barrier; and film economics. Additionally, many instances of coextrusion minimize the use of specific resins and the combination of thin layers improves the flex-crack resistance of barrier resins [1,2].

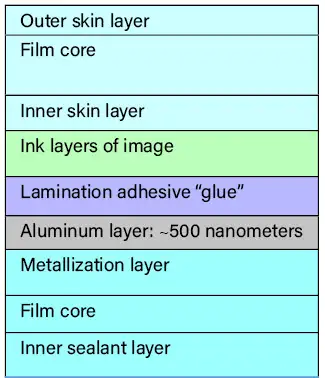

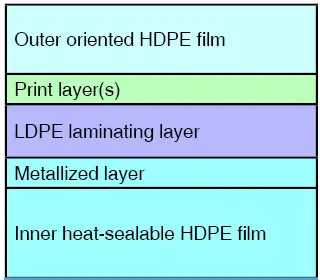

Impact of lamination adhesives

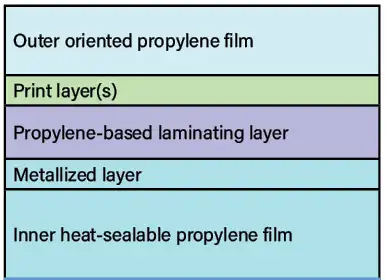

Using a single family of polymer still will have limitations based on the way laminates are prepared. Assuming the use of an adhesive lamination, it is pretty much impossible to maintain easy recyclability with any combination of polymers due to the chemical composition of most laminating adhesives. Use of an extrusion lamination could ease the problem as long as adhesive resins stay within the polymer family. This tends to suggest the use of ethylene-based polymer films for the bulk of the lamination (see Figure 3) or to substitute a propylene-based extrusion-laminating resin for the low-density polyethylene laminating resin widely used with oriented polypropylene films in existing extrusion-laminated products (see Figure 4).

It would be a great advantage to prepare an all propylene-based extrusion lamination by the development of a propylene-based extrusion-laminating/coating resin to replace the use of LDPE extrusion-laminating resins. In my mind, this would be more desirable than an all-polyethylene lamination due to the higher-use temperatures of oriented polypropylene compared to oriented polyethylene films and the smaller impact on the well-developed converting processes for oriented-polypropylene films.

While there currently may be a lack of employed capacity for oriented-HDPE films, the technology to produce them on existing propylene orienters is well established [3,4]. Consequently, it should be possible to prepare all-polyethylene packaging laminations (see Figure 3) in place of oriented propylene-based laminations as shown in Figure 4. However, the properties of the all-polyethylene laminations will be considerably different than those of an oriented-propylene lamination.

Changes such as these to the base films and/or the laminating resins, while possible, generally are constrained by the need to modify existing processing equipment to accommodate the property changes inherent to the material changes. For example, the change to an all-polyethylene lamination from a polypropylene-based lamination will require changes due to the lower melting point of polyethylene vs. polypropylene. Almost every aspect of the converting process on existing converting equipment would need to be changed, from line speed and tension levels to all processing temperatures, such as in metallization, on printing equipment and at extrusion lamination. These changes are all possible but make it more difficult to run multiple materials on the same processing equipment while maintaining film economics, at least in the short term.

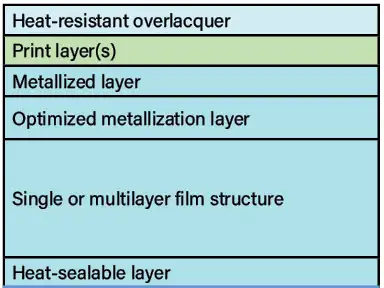

An alternative approach would be to replace the lamination itself with a monoweb produced from a single polymer family coextruded film (see Figure 5). But to maintain existing barrier properties and current product marketing, it would be necessary to metallize the outermost film’s surface, followed by surface printing on the metal and then over-lacquering the surface printed ink. This approach has been explored and developed over the years but has not significantly replaced laminations to date.

Packaging machine changes

Modern packaging machines are highly developed and designed for specific polymer combinations with some ability to change between lamination compositions. However, packaging speed, process-temperature changes and sometimes sealing-equipment changes generally are necessary to change between lamination compositions to optimize package formation and package integrity. To limit the packaging material to a single polymer family will require focused machine modifications and reduce the flexibility of the materials that successfully can be processed on the packaging machines.

Changes of this sort generally are evolutionary, requiring significant machine changes or replacement of existing installed machines. Due to the large inventory of existing machines, this is a heavy economic barrier to the rapid, wholesale change to single polymer-family packaging materials; not that it would be impossible but that it would be expensive and take time. Significant packaging machine changes were required to transition from cellophane-based packaging materials to oriented polypropylene-based packaging materials and required packaging machine changes, such as I have outlined above. This took many years and the redesign of new packaging machines to accomplish and the replacement of many packaging machines for oriented-polypropylene laminations to see applications throughout the packaging industry, and ultimately replace cellophane. This was all in spite of the many economic, environmental and property advantages of oriented-polypropylene laminations

Packaging property limitations

Moving packaging applications to a single polymer family to ease recyclability will have a profound impact on packaging properties, especially for oxygen and moisture barriers. This approach essentially eliminates the use of metallization and the coextrusion of multiple polymer families (polyolefins and nylons or EVOH) so essential to the highly developed packaging films we employ today, and all for an imaginary improvement in film recyclability, of films which already are not post-consumer recycled.

Conclusions

While I believe it should be possible to produce single polymer-family packaging films, I don’t believe that the packaging-property limitations imposed by such an approach would outweigh the perceived benefit or improvement in recyclability. Such a change in packaging composition would significantly degrade packaging protection and lead to a loss of product and increases in societal cost all along the distribution and use chain due to a decrease in product shelf life with the new packaging materials.

The perceived recycling/waste stream problem is due in large part to the loss of incinerators and the increase in landfills as the primary form of waste disposal. The products we have been discussing generally are not recycled and have a fairly large energy content, which could be partially recovered by incineration. So, in my way of thinking, if you are going to modify packaging properties to improve the end-of-life properties at the expense of packaging protection, you might as well go back to waxed paper.

References

- Translation of Utility Model Application Publication Number: 60-27000, Application #54-84842, Mamoru Yoshimoto, Kyutaro Taleuchi, applicant Sumitomo Bakelite Co., Ltd., publication data August 14, 1985

- Motoishi, et al., US Patent 4,608,286, “Gas barrier multilayer packaging material having excellent flexing endurance,” August 26, 1986

- Larter et.al., US Patent 6,689,857 B1, Feb. 10, 2004

- Tien-Kuei Su et. al., US Patent 6,168,826 B1, Jan. 2, 2001

Eldridge M. Mount III, president of EMMOUNT Technologies LLC (Canandaigua, NY), has 40 years of industrial experience in the extrusion and orientation of polypropylene and polyester films at ExxonMobil Chemical and ICI Americas Film Divs. He holds a Ph.D. in Chemical Engineering from Rensselaer Polytechnic Institute. Eldridge writes the “Substrate Secrets” Q&A column and moderates the “Substrates” Technical Topics online channel for this publication. He can be reached at 585-223-3996, fax: 585-919-6504, email: emmount@earthlink.net, www.emmount-technologies.com.

Are packaging films practically recyclable back into their original production streams?

Modern orientation equipment for producing oriented films operates at or near 6,000+ kg/hr (14,000 lbs/hr) and in excess of 300 mpm (1,000 fpm), depending on product details. While almost all of the scrap produced within the production facility, generated during the production of finished film, is recycled back into the production process, the ability to collect, transport, clean, separate materials and pelletize post-consumer waste for adding to the film line practically is impossible.

Let’s examine this statement in more detail using some typical modern snack packages. Figure 6 shows three typical snack-food packaging laminations easily found in your local supermarket. While there are smaller single-serve vending sizes, these three are representative of common packages for home use. These packages are oriented polypropylene-based extrusion laminations with low-density polyethylene. The outer oriented polypropylene films are both metallized and with 100% ink coverage.

Re-extrusion of these complex packaging materials will produce a raw material that could not be added to a film line to produce the starting films used in the lamination; they are just too “dirty” to add to the film line. While in principle they could be chopped and separated into three pieces (the inner metallized film, the lamination resin and the outer printed film) and the metal and ink removed, this is a slow, wet-chemical process that is expensive and has its own environmental waste problems. It would not be possible to separate the coextruded layers of the clean propylene-based materials into their component copolymers and homopolymer propylene. So, while it’s possible to separate the lamination, it is not practical or cost-effective and does not generate the original starting polymers.

But even more daunting is obtaining sufficient quantities of the films to transport to recycling facilities. The three bags pictured (see Figure 6) weigh 3.635 gm, 4.759 gm and 11.606 gm for the Cracker Jack®, Cheetos® and Wegmans® Chips bags, respectively. Assuming that 70% of the weight is recoverable polypropylene and propylene-based copolymers, it would take 2,492,000 Cracker Jack, 1,904,000 Cheetos and 782,355 Wegmans bags every hour to produce film. Even at a 20% use rate, this is a practically impossible and hugely expensive undertaking to collect, bale, transport, separate films from ink and metal, repelletize and transport to the film line.

So, I conclude that it is impractical to recycle post-consumer packaging but, because they are polymers, I think it better to incinerate them to recover the energy content inherent in the polymer than put them in a landfill.

– EMM