For the production and processing of flexible plastic and fiber-based webs, a homogeneous web-tension distribution is crucial for quality. However, new low-complexity, natural fiber-based or recycled materials in particular exhibit more fluctuating properties and narrower process windows than established materials. Flatness deviations, wrinkles, inclusions or processing-induced stresses have a far more critical effect here, says new research by Dresden, Germany-based Fraunhofer Institute for Process Engineering and Packaging (IVV).

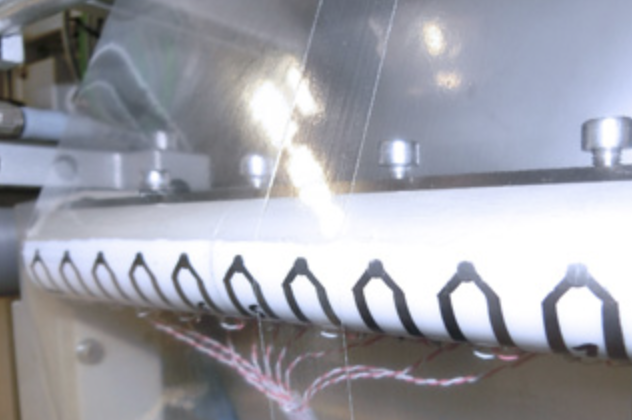

To prevent quality fluctuations and downtime, it is necessary to detect deviations as early as possible and react to them. In the “InKraftSens” research project, Fraunhofer IVV is developing a new method that uses thin-film temperature sensors to enable near real-time inline measurement of the web-force distribution and thus its inline control in the future. The measuring method is based on the change in heat transfer as a result of the contact between the web and the measuring unit as the web force varies. Sensors record the resulting temperature change on the surface of the measuring unit in real time and with high resolution. These temperature differences reflect the web-force distribution.

The area of application for the measuring system and method ranges from the manufacture of technical products to the packaging of consumer goods and the finishing of flexible materials. The technology solution supports the requirements for adaptive machines, product safety and minimal resource consumption and makes it easier for companies to switch to sustainable, recyclable-packaging materials.

More info on the technology development or collaboration on this project, contact Fraunhofer IVV at +49-351-436-1434; https://www.ivv.fraunhofer.de/en/contact.html

The next project meeting will take place on Dec. 4, 2024, in Dresden.