By David Ventola, business development dir.-Clean Technology Systems, Dürr Systems, Inc.

Introduction

Electric vehicles (EVs), whether cars, bikes or buses, rely on lithium-ion (Li-ion) batteries for power. With the increasing popularity of electromobility, the demand for these batteries has skyrocketed, resulting in the construction of new battery factories worldwide. However, the battery-production process in many aspects largely determines the ecological impact of electric vehicles.

To produce battery electrodes as sustainably as possible, it is critical to address the challenge of solvent recovery. Combined with a distillation system, a solvent-recovery solution can reduce CO2 emissions by up to 3,000 tons annually for a medium-sized coating line. An added benefit of this technology is the recovery of more than 95% of the costly N-Methyl-2-pyrrolidone (NMP) solvent, which is returned to the coating process.

Rising battery demand means an increase in battery-production plants

The EV industry faces not only long lead times for semiconductors but also for lithium-ion cells, and the global demand for batteries will continue to rise. The International Energy Agency predicts it will increase more than six-fold by 2030 [1]. The biggest driver is the automotive industry because batteries are a key technology for electromobility. As the main component of an electric car, they also play an important role in sustainability along the entire value chain. In North America, production capacities are expected to increase from 60 GWh to 1,267 GWh by 2036 [2]. Battery production, with its intensive energy and resource consumption, offers excellent potential for optimizing sustainability-related initiatives.

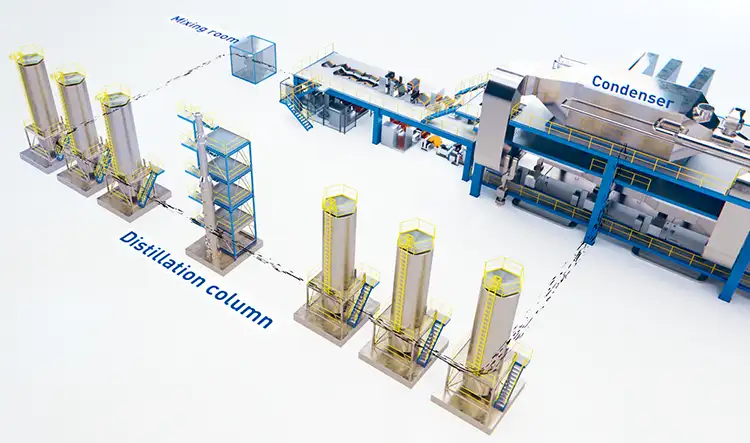

Greenhouse gas emissions (GHG) and environmentally harmful substances must be reduced or avoided at every production stage to produce batteries responsibly. This firm has developed an electrode-production, closed-cycle technology that enables solvents to be reused and meet the highest emission standards (see Figure 1).

Innovative solution enhances electrode-coating efficiency and sustainability

Electrodes are an integral part of every Li-ion cell. Every battery cell consists of two electrodes, with active materials coated on very thin aluminum or copper films, that act as a holding location for the lithium-ions that migrate back and forth during charging and discharging. Films are coated with a 50- to 150-micron-thin layer of graphite on the anode, and a slurry made of nickel, manganese, cobalt and lithium in a precisely defined ratio on the cathode. Extreme precision is required since poor coating quality impairs the battery’s function to the point where it could fail. The standard method uses the NMP solvent to dissolve the binder for the active materials employed in cathode coating. Classed as a hazardous substance, NMP must be used cautiously but is indispensable in series production due to its excellent solvent properties. NMP is an expensive operating material, averaging approximately $3,885 per ton.

Dürr engineers and scientists developed a closed-loop solution to meet these challenges (see Figure 2). Its solvent-recovery system removes solvents from the exhaust air of electrode-coating systems while recovering the heat. Combined with the equipment’s distillation columns, the operations can recover more than 95% of the NMP solvent for reuse in the mixing process.

If coating lines operate without NMP recovery – as often happens with outdated systems – thermal treatment of the exhaust air is required, releasing a great deal of environmentally harmful CO2 while increasing solvent-supply costs. An average-sized coating and drying system typically vaporizes between 600 and 2,000 lbs of NMP/hr to dry the electrode after the slurry is applied.

The environment and battery makers benefit

A state-of-the-art, solvent-recovery solution conserves air and water resources in multiple ways (see Figure 3). A closed-loop operation mode means that a medium-sized, cathode-coating line with a 38,000-SCFM (standard cubic ft/min) airflow rate requires only approximately 1,200 SCFM of fresh air, which has two positive effects. On the one hand, the downstream adsorption system needs to purify a reduced quantity of fresh air. Comparing the solvent concentration shows how efficiently this is achieved. While the oven’s solvent concentration typically is about 0.00031-0.00093 lb/ft3 of air, it only is 0.000062 lb/ft3 in the air released into the environment. The second advantage of adding so little fresh air is that it minimizes the amount of moisture getting into the system. Because NMP is hydrophilic, the NMP must be separated from the water through distillation before it can be reused, consequently increasing the quality of the processed NMP.

Heat management must be balanced to achieve optimum results. Heat displacement built into the loop recovers more than 80% of the heat with innovative heat exchangers, which cools exhaust air and causes the NMP to condense as well as transfer heat energy from exhaust air to the air recirculated to the oven. Condensers are used to recover energy from the exhaust air and ensure consistent process conditions with low energy input, even when it comes to anode coating, where water is the typical solvent.

The adoption of an efficient solvent-recovery system, combined with an effective distillation system, provides benefits to manufacturers by reducing costs and to the environment by minimizing energy usage and resource consumption.

References

- Global EV Outlook 2023 of the International Energy Agency, www.iea.org/reports/global-ev-outlook-2023/trends-in-batteries

- Battery-News.de. “Announced Battery Cell Production Capacities America.”

David Ventola, business development dir. for the Clean Technology Systems division at Dürr Systems, Inc. (Southfield, MI), holds a Bachelor of Science and a Master of Science in Chemical Engineering and an MBA. He spent most of his career in the roll-to-roll and converting industry at Polaroid and Presstek. Just prior to joining Dürr Systems, he spent five years at A123 Systems focused on lithium-ion battery-electrode manufacturing. David can be reached at 248-450-2000, email: david.ventola@durrusa.com, www.durrusa.com.