By Darrell Landry, technical sales representative; Jaclyn Epstein, sales & marketing strategy mgr.;

and Jessi Spadaccino, communications manager, Mica Corporation

Adhesion promoters are a critical component in the manufacture of standard polyethylene-coated paper hot cups because they offer added performance and functionality. As the demand for sustainable solutions for single-use packages increases globally, however, many converters have taken steps to create commercially compostable hot cups using inherently compostable materials, such as bio-based resin and paperboard. The challenge converters are facing, though, is that to create a truly compostable hot cup, all materials must be able to degrade into the environment safely, including adhesion promoters which are not inherently compostable. Without a viable compostable replacement for polyethyleneimine (PEI) primers, it has been challenging for converters to produce hot cups with the same performance and functionality that consumers have come to expect. However, a new-to-market compostable adhesion promoter may be able to help converters solve this challenge. This paper will compare the application specifics, regulatory requirements, process conditions and performance of traditional PEI primers and the new water-based compostable adhesion promoter in hot-cup applications.

Introduction

More than 105 million disposable hot cups are used in the United States every day, and many of them end up in landfills and in our environment [1]. Consumers around the world are demanding solutions to this global waste problem, and many major brand owners have responded by setting aggressive sustainability goals and initiatives promising to create packages that contribute to a circular economy. One approach to mitigating single-use packaging waste would be to create 100% compostable hot cups. In the proper conditions, compostable materials do not leave any toxic residues behind and can help condition the soil in which they degrade. However, until recently, the road to creating multilayer, compostable packages and containers for consumables has been challenging.

For any hot cup to make it to market, the manufacturing process, performance specifications and regulatory requirements for all ingredients need to be thoroughly evaluated, understood and approved. When it comes to compostable cups, all of the above requirements need to be met, but the finished product also needs to pass a series of rigorous compostability tests before a converter can claim the structure is compostable and/or obtain compostable-product certification.

Materials such as bio-based resins and paper are great for compostable hot-cup applications because the manufacturing process is similar, they typically have the proper regulatory compliance and these elements inherently are compostable. However, most of these materials do not achieve the necessary performance requirements on their own and need an adhesion promoter to enhance seal strength, improve printability and reduce wicking or staining.

Due to strict testing requirements, converters are not able to use standard polyethyleneimine (PEI) primers to improve performance in compostable products if they want to pass rigorous compostability testing, such as ASTM D6400, and/or obtain compostable certification. A newly developed compostable adhesion promoter is proving to be viable in hot cups, and other multilayer, compostable structures. Observational and lab data in this paper will compare the performance of the new compostable adhesion promoter and a widely used, water-based PEI adhesion promoter in hot-cup applications.

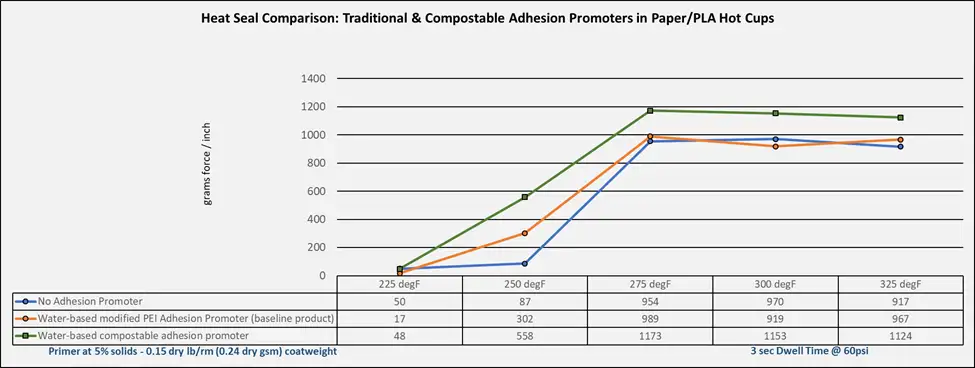

Figure 2. Example of a well-formed rim; and

Figure 3. Hot-cup rim with a flagger defect.

Hot-cup application specifics

A typical paper hot cup structure is made from paperboard stock that is extrusion-coated on one side, traditionally with low-density polyethylene (LDPE). The cup stock is printed and then die-cut into cup blanks. The blanks then are loaded into a cup-making machine to form and seal into a paper cup.

Cup-making machinery has improved substantially over the years. While older machinery produced up to 180 cups/min, new high-speed cup-making systems can turn out up to 320 cups/min. At these high speeds, the dwell time in each sealing station is less than one-fifth of a second. These sealing conditions make cup-forming more difficult with one-side, LDPE-coated paperboard.

In addition to increased line speeds, in recent years the LDPE-extrusion coatweight for hot-cup applications has been reduced from 1.0 mil (14.4 lbs/3,000 ft2) to the now typical 0.75 mil (10.8 lbs/3,000 ft2) to keep up with competitive demand. This reduction in coatweight has increased significantly the potential for a common defect in hot cups known as “flaggers.”

Flaggers occur at the rim of a paper hot cup, at the top of the sidewall seam. In this area, the thickness of the rim sealing area is double that of the rest of the sidewall. Due to the thickness along the sidewall seam, the forming of the cup rim causes an area of higher pressure, which thins the polymer-extrusion coating significantly. Poly-thinning is the primary cause of the flagger defect (see Figures 1-3).

A typical flagger allowance would be two occurrences or less per 1,000 cups made. More than two occurrences would cause the production to be considered substandard, and in many cases, the entire batch of cups would be rejected by the customer.

To minimize the formation of flaggers, many cup-makers traditionally have applied modified PEI adhesion promoters on the uncoated side of the paper hot-cup sidewall stock. This process allows the extruded coating to have higher bond strengths in the area where flaggers typically occur.

Compostable hot-cup structures are similar to standard ones, but instead of an LDPE coating on one side, an inherently compostable bio-based resin (polylactic acid (PLA) or polyhydroxyalkanoates (PHA)) is used. However, just as with typical hot cups, due to the high-speed cup-making machinery and the need for a better performing final product, an adhesion promoter often is needed to manufacture a compostable final product. This firm has recently developed a compostable adhesion promoter (CAP) to meet this market need.

Comparison testing

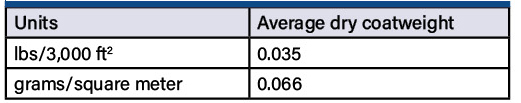

A heat-seal screening study was conducted tocompare the heat-seal strength of PLA to paperboard with and without the PEI primer and the CAP. In this comparison, a baseline water-based, modified PEI adhesion promoter used widely in the industry was tested.

The heat-seal curves in Figure 4 suggest that the PEI primer and CAP will increase heat-seal strength on PLA-coated cup stock, but the CAP performs significantly better at higher temperature ranges.

Additional benefits of adhesion promoters in hot cups

In addition to increasing heat-seal bonds, the application of an adhesion promoter, including the new CAP, on the uncoated side of the paperboard offers several additional benefits for cup makers.

- Printability: a thin layer of a water-based adhesion promoter enhances the paperboard surface for printing.

- Stain-reduction: the inside edge of the sidewall seam sometimes can show staining when exposed to dark hot beverages, such as coffee. This staining occurs when hot material begins wicking into the exposed edge of the paper. The presence of a traditional or compostable, water-based adhesion promoter on the uncoated side of the paperboard has been shown to reduce the rate of wicking, thus reducing staining.

- Non-yellowing technology: the compostable adhesion promoter dries clear.

Compostability testing and regulatory compliance

Many companies are choosing to obtain compostable-product certification for food packaging and other structures from the Biodegradable Products Institute (BPI), North America’s leading certifier of compostable products and packaging. The certification process verifies that the overall structure and all components of the package meet compostability standards, such as passing the ASTM D6400 standard.

Compostability testing: ASTM International is one of the world’s largest international standards-developing organizations [2]. Multinational corporations and organizations worldwide have applied and referenced the ASTM D6400 specification [3], which covers plastics and products made from plastics that are designed to be composted in municipal and industrial aerobic composting facilities [4].

BPI uses ASTM D6400 and additional procedures to test all aspects of a product’s composting process, including:

- Chemical characteristics (Metal limits for the US are 50% of those prescribed by CFR 503.13 (Pollutant Limits) Table 3 (per ASTM 6400-12 requirements)

- Disintegration (less than 10% particles remaining larger than 2 mm)

- Biodegradation (greater than 90% CO2 conversion, 6-month time period)

- Ecotoxicity (no harmful effect on plant growth)

- PFAS Fluorine Analysis (additional test outside of ASTM D6400 required by BPI)

This firm’s new CAP passes all of BPI’s compostability testing as a standalone product.

Regulatory compliance: As in all food packaging, regulatory compliance is critical in hot cups. One way many adhesive manufacturers can determine whether a product is safe in food applications is to go through a review process with a firm that specializes in regulatory law. These firms can determine the appropriate uses and maximum coatweights of the compostable adhesion promoter. Some adhesion promoters, including the CAP, fall under specific FDA Conditions of Use. For food-contact substances, if there is a temperature restriction for the product’s intended use, the Conditions of Use need to be specified by reference.

The CAP has been approved for use as a coating or primer on hot or cold beverage cups with a maximum coatweight of 0.29 lbs/3,000 ft2 or1.79 dry gsm under FDA Conditions of Use B-H.

Conditions B-H are as follows [5]:

- Condition of Use B, Boiling-water-sterilized

- Condition of Use C, Hot-filled or pasteurized above 150° F.

- Condition of Use D, Hot-filled or pasteurized below 150° F.

- Condition of Use E, Room-temperature-filled and stored (no thermal treatment in the container)

- Condition of Use F, Refrigerated storage (no thermal treatment in the container)

- Condition of Use G, Frozen storage (no thermal treatment in the container)

- Condition of Use H, Frozen or refrigerated storage: Ready-prepared foods intended to be reheated in container at time of use

Adhesion-promoter application processes

The recommended dry coatweight of the CAP can vary based on paperboard type and operating conditions of the extrusion and primer-application equipment. The average dry coatweight for the CAP in paperboard hot-cup applications is shown in Table 1. This coatweight is comparable to the coatweight used when applying PEI adhesion promoters.

There are two general processes that can be used in the application of the CAP in paper hot-cup structures: in-line coating and off-line coating.

In-line coating process: In an in-line process, the adhesion promoter is applied on the paperboard during the extrusion-coating process. The coating station generally is located between the primary unwind and the extrusion-coating station. In most cases, this equipment is located just ahead of flame surface-treatment equipment. The primary purpose of the flame treatment is to modify the surface chemistry of the paperboard to promote better bonds to the extruded PLA.

The flame-treatment system helps dry the residual moisture left after the adhesion promoter is applied. Some of the residual moisture is absorbed by the paperboard, but the surface moisture on the primed side must be dried thoroughly to activate the adhesion promoter. The level of drying required is dependent on the amount of adhesion promoter applied and the level of residual moisture in the paperboard. When higher coatweights are applied, more flame treatment will be required to dry the adhesion promoter on the paperboard.

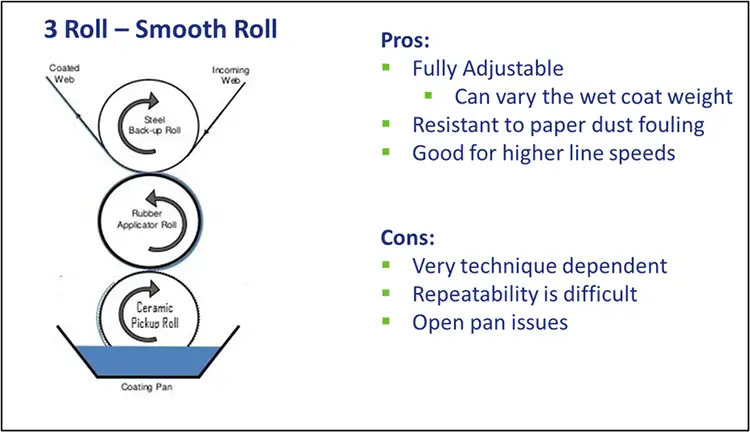

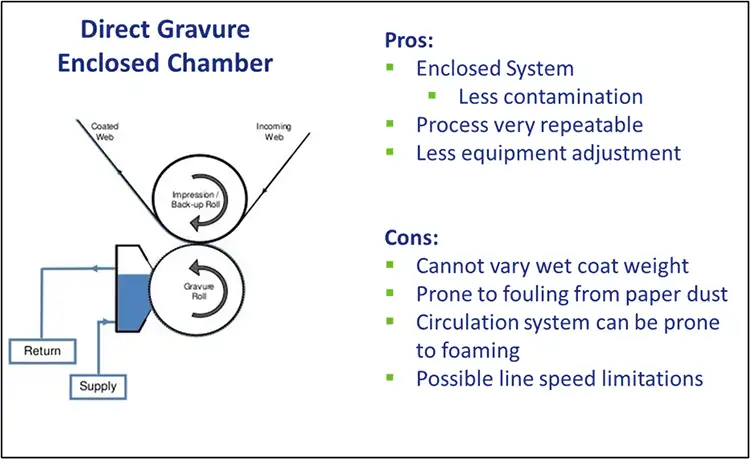

The two most common types of applicator systems used in paper hot-cup structures are smooth-roll applicators (see Figure 5) and an enclosed chamber with direct-gravure applicators (see Figure 6). The smooth-roll applicator is more commonly used for in-line, paperboard-coating operations. Listed below are the advantages of using a smooth-roll applicator.

Application-rate adjustment: the application rate can be adjusted in several ways on this system. Roll speeds and directions can be varied to change application rate. The gaps between the rolls also can be varied to change the application rate.

Minimal roll fouling: the cells of a gravure cylinder can build up (foul) with paper dust. This fouling reduces the applied coatweight over time. The smooth cylinder will not foul, as it is self-cleaning.

Off-line coating process: In an off-line coating process, the adhesion promoter is applied after the extrusion process is complete, generally on a printing press, and in many cases, as part of the printing of the cup stock. Most printing presses have long exit dryers designed to adequately solidify the inks and coatings. Typically, the last printing station on the press is used to apply the adhesion promoter. The coated paper then immediately goes through the exit dryer to dry completely.

An enclosed chamber with a direct-gravure applicator is the most common type of applicator used when applying an adhesion promoter post-extrusion. The cell volume on the gravure cylinder applies a specific wet coatweight (wet delivery rate) of the adhesion promoter. To apply the correct dry coatweight, the adhesion promoter should be diluted based on the wet delivery rate of the gravure cylinder. Diluting the adhesion promoter reduces the % solids of the solution to a concentration that applies the desired dry coatweight.

There are several advantages to using this system; ease of use is one of them, as the direct-gravure applicator requires very few adjustments and therefore less skill is needed to operate it. However, more maintenance is required for this system type. The gravure cylinder should be cleaned between uses to prevent buildup in the cells.

Conclusions

Data presented in this paper suggest that the new-to-market, compostable, water-based adhesion promoter can replace traditional adhesion promoters in certified-compostable PLA and paperboard hot-cup applications while still providing the performance benefits and functionality converters have come to expect from traditional PEI primers. The new CAP can help reduce the occurrence of flagger defects, minimize staining in the sidewall seam and improve printability without slowing down production or making major changes or improvements to the extrusion-coating line. Furthermore, environmental concerns likely will continue to drive the paper hot-cup market to develop products that address sustainability concerns of consumers and brand owners. Compostability is one way to address these environmental concerns. With the introduction of bio-based polymers and a new compostable, water-based adhesion promoter, hot-cup printers/converters can create certified-compostable hot cups.

Acknowledgements

The authors would like to thank Tammy Cheng, Mike Chen and Elaine Lo for collecting and analyzing the data included in this paper.

References

- Freedonia Group; “US Cups and Lid Study,” www.freedoniagroup.com

- ASTM International, www.astm.org

- Bringing New Life to Plastics; Standards for Biodegradable and Biobased Plastics by Patricia Quigley, www.astm.org/SNEWS/MJ_2009/quigley_mj09.html

- Biodegradable Products Institute; ASTM D6400- Test for Compostability, https://bpiworld.org/page-190422

- FDA’s Multiple “Conditions of Use” by George G. Misko, Esq., www.foodsafetymagazine.com/

Darrell Landry, technical sales representative for Mica Corporation (Shelton, CT), has more than 35 years of experience working in the paper, pulp and packaging industry, and led the application development for Mica’s new compostable adhesion promoter in hot cups. He is the Technical Program Chair for the TAPPI International Flexible Packaging and Extrusion Div. and is an active member of AIMCAL. Darrell can be reached at 203-446-9729, email: dlandry@mica-corp.com, www.mica-corp.com.

Jaclyn Epstein, sales and marketing strategy manager at Mica Corporation, has worked in a variety of corporate communications roles at General Electric prior to joining the paper, pulp and packaging industry in 2014. She is the Division Chair of the TAPPI Young Professionals Division and is a member of AIMCAL. Jaclyn can be reached at 203-446-9711, email: jepstein@mica-corp.com.

Jessi Spadaccino, communications manager at MICA Corporation, has been working in the paper, pulp and packaging industry for more than eight years. She is the Director of Communications for the TAPPI Young Professionals Division, is part of the TAPPI International Flexible Packaging and Extrusion Division’s Digital Team and is a member of AIMCAL. Jessi can be reached at 203-922-8888, email: jspadaccino@mica-corp.com.