By Rosalyn Bandy, vp-Sustainability, TLMI

Abstract

With the advent of The Circular Economy, the pressure-sensitive label industry is working hard to do its job to support brands and retailers with their sustainability goals. But, what about the label industry’s own circularity around release liner? Many challenges still exist, but there are significant developments to make note of, especially around TLMI’s work to recycle PET release liner.

Introduction

The concept of sustainability has evolved in recent years to the idea of circularity. The Ellen MacArthur Foundation, whose mission is to accelerate this type of economy, describes it as moving from a “take-make-waste extractive industrial model” to a circular model that “aims to redefine growth, focusing on positive society-wide benefits.” Circularity – also known as The Circular Economy – is based on three principles: 1) design out waste and pollution, 2) keep products and materials in use, and 3) regenerate natural systems [1]. A component of The Circular Economy is The New Plastics Economy Global Commitment, which focuses on companies doing their part in reducing unnecessary plastic packaging [2].

When it comes to packaged, consumer goods, we are seeing this in play from brands and retailers that have publicly stated commitments to increase the use of recycled content in materials, increase recyclability, have zero waste in supply chains and have zero plastic waste. One only has to look at Walmart’s Sustainability Hub to see the comprehensive nature of this movement [3].

Liners a “specialty” recycling item?

Much of the label industry is strongly supporting its customers with labels (face stocks, adhesives, inks) that are not detrimental to recycling plastic containers (as defined by the Assn. of Plastic Recyclers) or fiber containers (as defined by the USDA Forest Products Laboratory), but what about the byproducts coming from the pressure-sensitive label industry? Of particular concern is release liner, because that byproduct is generated at the end-user of label products – the copacker, the brand owner, the retailer. By some accounts, release-liner byproduct generated in the US totals more than 400,000 tons annually [4]. Most of this material ends up where the rest of the wastestream ends from any particular site because it is not considered recyclable by municipal standards – it is a specialty recycling item (see Figure 1).

PET release liner: With the advent of chemical recycling several years ago, TLMI consulted with a longtime friend and entrepreneur who started a new business recycling carpeting, through a chemical process, into virgin-like monomer pellets. We worked together testing his process on PET release liner. It worked, and now there is a solution for recycling all PET release liner in the US with additional locations coming on-line. Because there is demand for the recycled pellets, this company also pays for the PET release liner to help offset the shipping costs to the processor.

TLMI worked to develop a specification sheet so generators of the release liner understand exactly how their materials need to be shipped and what percentage of labels can remain. This is a success story to celebrate, and it seems that PET liner will only increase in its capacity to be recycled as other companies get on board the chemical recycling train.

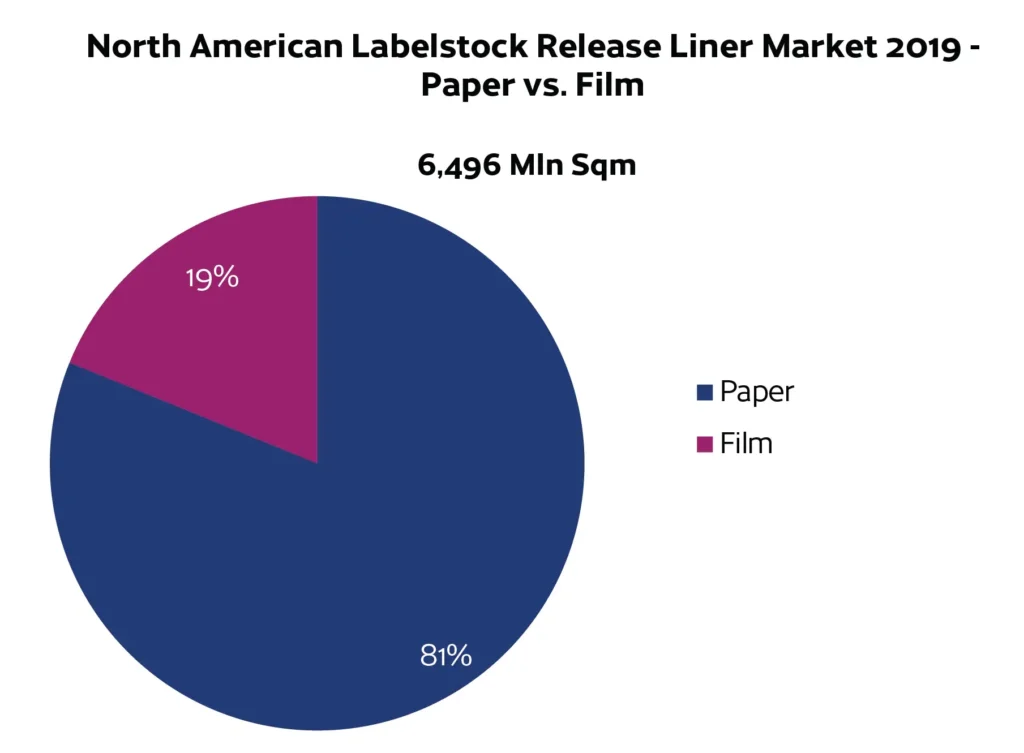

Paper release liner: According to AWA Alexander Watson Associates research, 81% of release-liner byproduct generated in North America is made from paper [4], and the recycling options for paper release liner have become slim to none (see Figure 2). It seems this is primarily due to the abundance of other paper streams that are not silicone-coated as well as the downturn in domestic recycling. At TLMI, our project work is through committees, and the environmental committee is dedicated to the task of finding new recycling options. Currently, committee members are setting up meetings with large paper companies focused on tissue and towels and other industries that may be seeking clean, long fiber

for reuse.

Once recycling options for paper release liner are secured, we know that TLMI converter members have the knowledge of where this material is generated by their customers. We know they are willing to assist their customers in any way possible to get the material recycled (One converter is even willing to print the reverse of his release liner with instructions on how to recycle it).

The obstacles

Whether PET or paper release liner, TLMI has identified a number of obstacles in the process of recycling these byproducts:

- There are no incentives, such as legislation or cost savings, to encourage generators of this material to recycle it.

- Sometimes companies can break even, but most often it costs more than landfilling to recycle the material.

- There is a cost to have the material preprocessed, if necessary (such as compacted, baled, labels removed), to meet the recycler’s specifications.

- There is a cost for shipping the material and often a tipping fee at the recycler.

- To ship efficiently, full truckloads are required, which often means needing a place to store the material until a full truckload is accumulated.

- A supply and demand market for paper liner, in particular, needs to be created in which there is a profit to be made.

- Paper release liner, while perfect to be recycled into tissue and toweling, does not seem to be of interest by tissue and toweling companies when so much other post-consumer paper is available.

TLMI’s approach

TLMI committees have found that the best way to handle these challenges is to approach them by small regions. In Fall 2019, we had our first regional label byproduct summit in St. Louis, MO. We invited local printers of all types, label converters, local TLMI supplier members, local recyclers, logistics specialists and a baler company. Most of these companies were located within 150 miles and, for a few hours over lunch, we discussed each company’s service capabilities, the obstacles at hand and how we might all be able to problem-solve within this region to help divert printing byproducts from landfills. Coalitions still are being built, and the attendees now have awareness of the resources in their area.

Our next label byproduct summit will take place this fall and will be a virtual event due to the COVID-19 pandemic. We plan to duplicate our pilot program with a focus on providers within 150 miles of Lansing, MI. We are brainstorming how to effectively turn a full afternoon “lunch-and-learn” into a very concise 90-min webinar.

Conclusion

It is clear that many of the release-liner recycling challenges that have existed for years still exist, and it seems that, at least right now, we have more questions to explore than answers to provide. But, we are confident in our abilities as an aligned and persistent group that is moving in the right direction. As anthropologist Margaret Mead once said, “Never doubt that a small group of thoughtful, committed citizens can change the world; indeed, it’s the only thing that ever has.”

References

1. https://www.ellenmacarthurfoundation.org/circular-economy/concept

3. https://www.walmartsustainabilityhub.com/project-gigaton/packaging

4. https://www.awa-bv.com/product/global-release-liner-annual-review-2020/

Rosalyn Bandy, vp-Sustainability for TLMI (Milford, OH), the US trade association for the label industry, holds dual Master’s degrees in Environmental Science from SUNY Environmental Science and Forestry, and Public Administration from Syracuse University. At TLMI, she leads the association-wide conversation about how label converters, suppliers and label end-use customers can deliver business value through developing programs and products with environmental and social purpose. Bandy also serves on the board of directors of the Sustainable Green Printing Partnership and is an advisor on labels to the Assn. of Plastic Recyclers. She has been a sustainability professional for 15 years, serving in positions of increasing responsibility starting with natural resources (renewable energy and ecosystem services), green building, private-label packaging and labels. Bandy can be reached at 315-569-2009, email: rosalyn.bandy@tlmi.com, www.tlmi.com.