By Eric J. Reber, technical dir.-Mahlo America, Inc.

The in-line measurement of thin coatings on paper and film continues to challenge manufacturers, especially as performance tolerances and requirements tighten. New measurement techniques have been introduced recently which focus on thin coatings and employ optical measurement techniques to provide accuracies down to 0.01 micron. These measurement methods are non-nuclear and measure from a single side of the coated web and at a single location – after the coating is applied. This paper will discuss two of these new developments: 1) Solid-State Infrared Absorption, primarily for coatings on paper, and 2) Optical Interferometry for coatings on film, and will provide their operating principles and performance specifications.

Editor’s Note: This technical paper is an extension to one of the author’s earlier articles, “New non-nuclear weight / thickness sensor for the measurement and automatic profile control of extruded film, sheet and coating,” which appeared in Converting Quarterly 2019 Q3, pp. 38-43. Please reference that paper for more details on traditional NIR absorption measurement and the new solid-state NIR sensor.

NIR absorption method

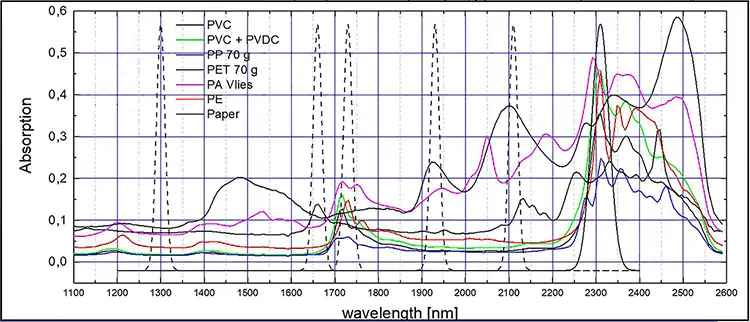

Traditional near-infrared (NIR) absorption measurement: NIR absorption sensors can be used to measure polymer films and coatings. Most organic molecules have unique NIR absorption spectra. When the web is illuminated with light in the near infrared range (typically 1,000 to 3,000 nm), these molecules absorb NIR light at wavelengths determined by their specific molecular bonds (see Figure 1). Band-pass filters selected to measure the absorbed light intensity at the absorption peak of the molecule of interest (for example, PET, PE or PP) are used in conjunction with filters centered at reference wavelengths to obtain a measurement of the mass or thickness of the web component. The more light that is absorbed at that molecule’s absorption wavelength, the more of those molecules are present in the web and, therefore, the greater the weight or thickness of the web or web component (e.g., coating).

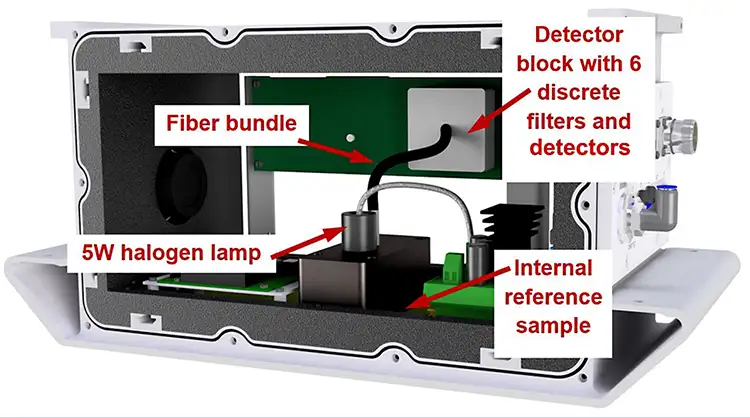

Existing older-design NIR sensors use a halogen lamp, a Lead Sulfide (PbS) light detector and a spinning wheel containing three, four or six filters. Such PbS detectors, however, are quite temperature-sensitive, rotating motors are subject to failure, and the time delay measuring the light through each filter in sequence can cause measurement errors with a moving web and scanning sensor.

New solid-state NIR absorption measurement

New detector: Advances in infrared-light detection technology have contributed to the development of a new on-line NIR basis weight / thickness sensor that is 100% solid-state with improved temperature stability and >10x finer resolution than existing rotating-filter wheel devices. Beginning with a new type of infrared detector, this firm’s new photodetector has a higher quantum efficiency, lower dark current and an ultrafast time response relative to the formerly used detector types. The much higher light sensitivity (~100x that of PbS detectors) means the new detector exhibits a much larger signal change for a very small target-weight or thickness change, so the overall system gain is much lower, reducing temperature effects. In addition, a new standardization technique re-zeros the sensor when needed to eliminate any residual sources of drift that may result from dirt, aging, etc. The higher detector resolution expands both ends of the traditional filter-wheel sensor’s measurement range to both lighter and heavier webs than previously available.

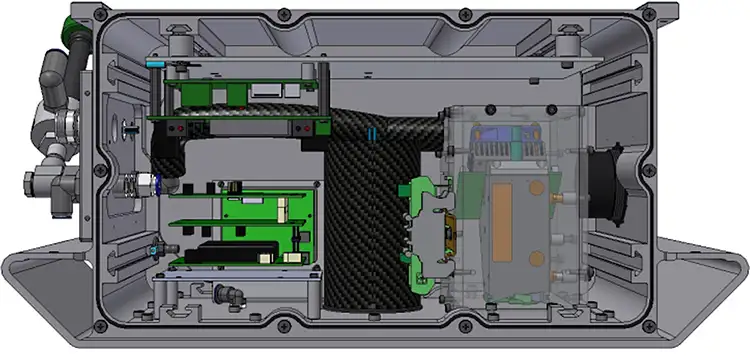

Solid-state array: A new ground-up design using the new detectors allows for the elimination of failure-prone, motorized, spinning-filter wheels. Six detectors, each with its own discrete narrow-band pass filter and a novel optical-fiber light pipe, provide true simultaneous same-spot measurements of all wavelengths very rapidly with no light modulation. This results in very fast, stable measurement with 100x finer resolution than that of older spinning-filter wheel devices. The use of an optical light pipe nearly parallel to the light source minimizes the effects of web flutter and can be configured with a small measurement spot for fine cross-direction (CD) resolution. The six-filter array design also facilitates the selection of custom filters for special applications. With no motors or other moving parts to accommodate, the solid-state sensor design is much simplified, easing access for the user to replace the lamp with the sensor remaining mounted on the scanner.

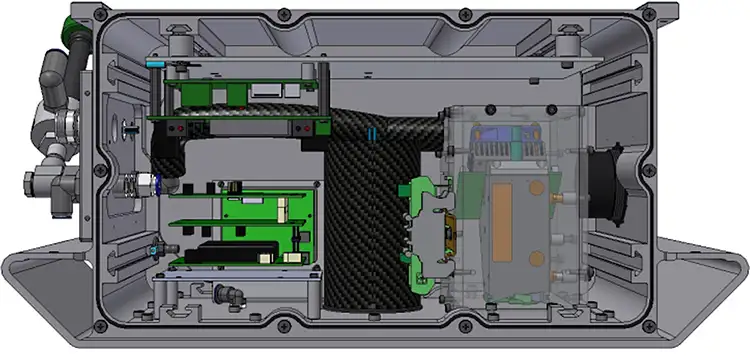

When used as part of an in-line scanning measurement system, the new solid-state NIR sensor (see Figure 2) is said to provide excellent CD resolution for accurate profile control and narrow defect detection. The new generation of NIR detectors also operate without special cooling requirements up to 60° C (140° F).

Sensor applications: The solid-state NIR sensor reportedly can measure both the moisture content and the basis weight / thickness of paper-web substrates and coatings with high resolution, accuracy and excellent defect detection. Its non-nuclear measurement technique is very selective and cost-effective, and the six-filter design allows for the simultaneous measurement of many of the listed parameters (see Table 1).

The small 6-mm (0.25-in.) measurement spot size and the rapid scanning capability made possible by the very low-noise new photodetectors make for an ideal component of an automatic measurement and control solution.

There are applications for which the coating cannot be differentiated from the substrate using an NIR-absorption technique, such as certain polymer coatings on chemically similar film substrates. In this case, another measurement technique may be used.

Optical interferometer method

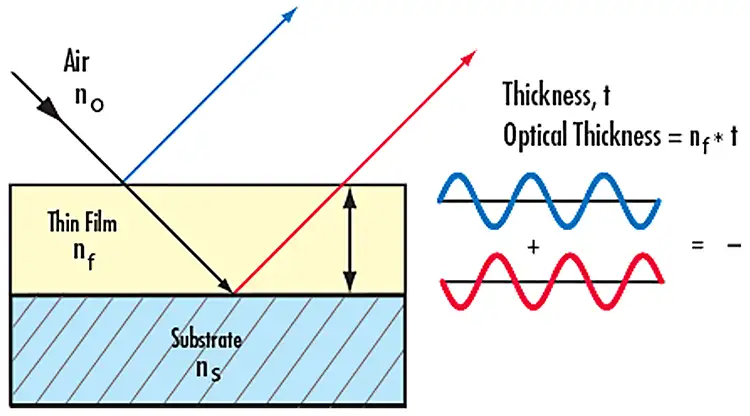

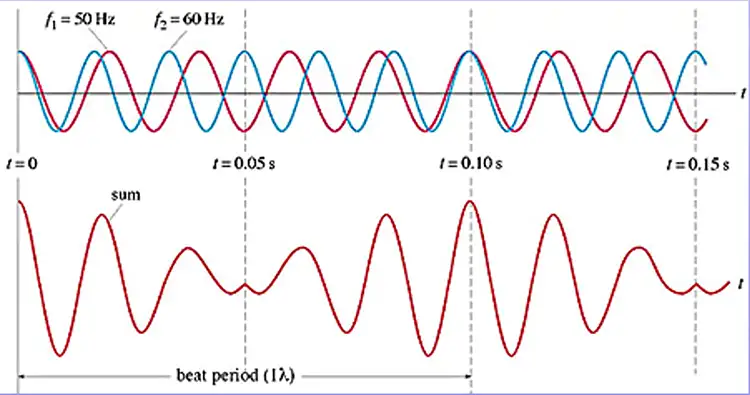

When exposing clear or slightly opaque thin coatings to UV radiation, visible or NIR light, the light is reflected from both the top and bottom surfaces of the coating (see Figure 3). These light reflections interfere with one another as a function of the different distances that each travel, creating an interference pattern that can be detected by a spectrometer (see Figure 4).

The frequencies of this interference are a measure of the coating thickness and determined using a Fast Fourier Transform (FFT) algorithm. Depending on the indices of refraction between the coating and the substrate, very high accuracy of up to 0.01 micron can be achieved.

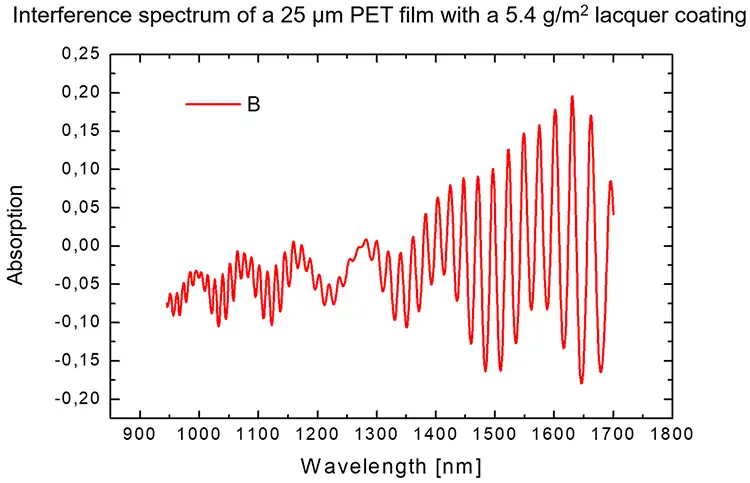

Figure 5 shows the raw interference spectrum for a 4.04-micron varnish coating applied to a 25-micron PET film.

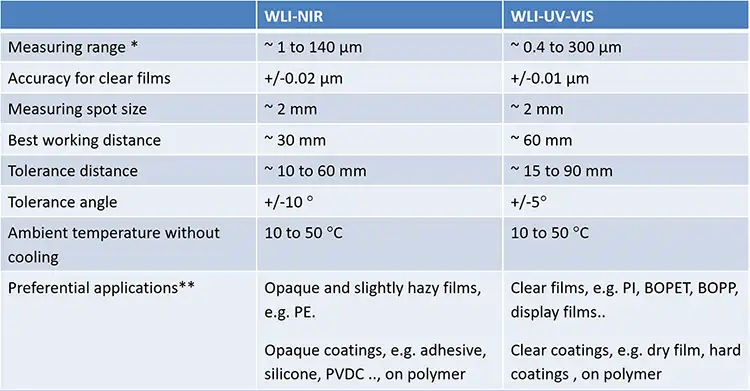

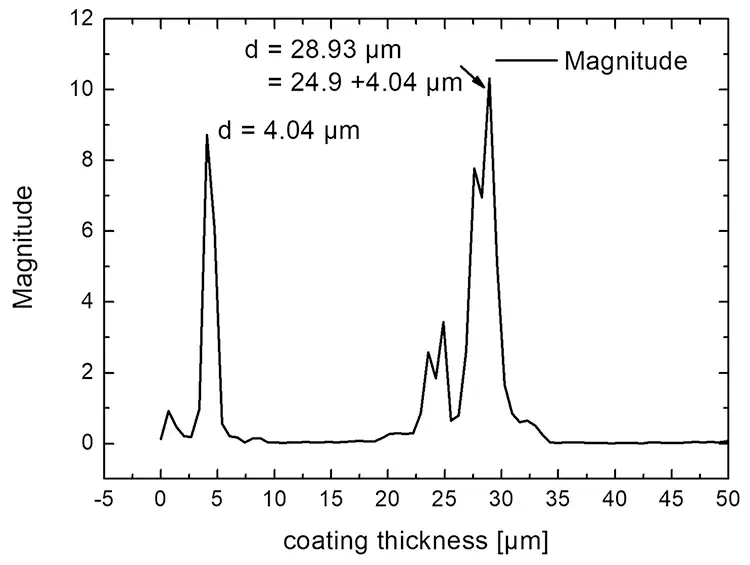

The frequencies of the interference are determined by an FFT algorithm using one of two spectrometers, Near Infrared (NIR): 940 to 1,700 nm, and Ultraviolet/Visible (UV-VIS): 350 to 1,020 nm. The FFT analysis (see Figure 6) results in very sharp peaks at the thickness of the total combined varnish + PET at 28.93 microns, as well as at the varnish coating peak at 4.04 microns.

In most cases, the total thickness and the coating / layer thicknesses can be measured simultaneously.

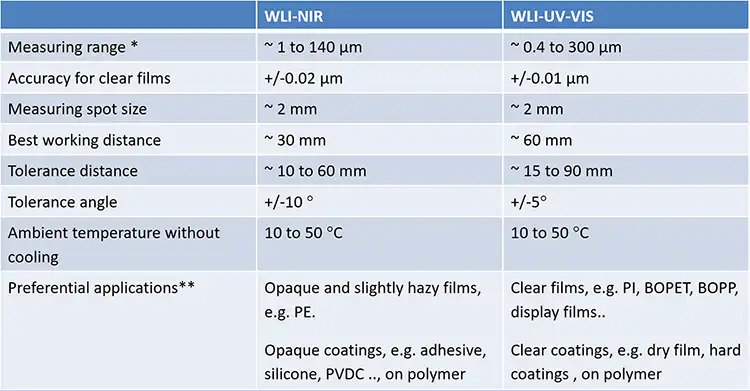

The optical interferometer sensor (see Figure 7) can measure coatings down to a thickness of 0.40 microns. Additional applications for the optical interferometer are PVDC coatings on PVC film, silicone-based release coating on PET and PE films, monolayer films and the total thickness of multilayer extrusions, such as packaging film, where extremely high accuracy is required.

In addition, the optical interferometer is able to determine even extremely thin coatings in the nanometer range indirectly with aqueous or solvent-based applications on films, depending on the % solids content (see Table 2).

Features of the optical interferometer include:

- Measures films, coatings and layers down to 0.40 microns thick

- Fast (<0.10 to 5 millisecond) measurement and very high stability

- Small measurement spot for excellent defect detection

- Very easy to calibrate

- Non-nuclear

- Single-sided measurement

Optical interferometer applications

Applications for the optical interferometer are wide-ranging, and the type of spectrometer needed also varies.

Monolayer films

- All polymers, thicknesses from ~1 to 300 µm (UV-VIS or NIR type)

Coatings

- Clear coatings on PET, metallized films, metal sheets (UV-VIS type)

- Adhesive coatings on soft films, e.g, PE, PP (NIR type)

- Colored lacquer coatings on aluminum (NIR type)

- PVDC on PVC (NIR type)

- Liquid solvent coatings (on PET and metallized PET) (NIR type)

Multilayer films (multiple layers simultaneously)

- Total thickness from ~1 to 300 µm (UV-VIS or NIR type)

- Thicknesses of coextruded layers, barrier layers (UV-VIS type) (refractive index dependent)

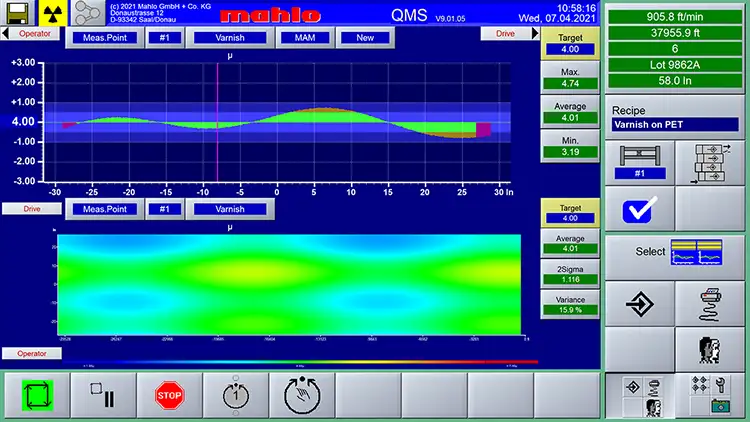

The coating thickness information can be compiled as complete roll reports in various formats. The high-resolution coating details also can be displayed in real-time in many forms, including numerical displays, bar graphs, SPC charts and as a cross-direction (CD) profile as in the top graph or as a two-dimensional trend as in the bottom graph shown in Figure 8.

Conclusion

The new solid-state NIR sensor will replace both older filter-wheel IR sensors and nuclear gauges for a more cost-effective, in-line measurement solution for polymer films and sheet, coatings on paper and moisture. For thin coatings on polymer films or poly-coated substrates, as well as thin monolayer or multilayer films, the optical interferometer provides a single-sided, non-nuclear measurement with extremely high resolution.

Eric J. Reber, technical director for Mahlo America, Inc. (Spartanburg, SC), holds advanced degrees in Physics and Mathematics from Marquette University (Milwaukee, WI). His web-gauging sensor development work began in the mid-1980s with Barber-Colman’s purchase of Indev Gauging. He set up a sensor design center for web gauging for Eurotherm International (now Thermo-Fisher Gauging) in Newberry, England, and headed up sensor development for NDC Systems (Irwindale, CA), where he was responsible for the development of NDC’s original beta transmission sensor and laser caliper sensor and O-frame scanner. Eric has numerous publications throughout his 35+ years in the web-gauging industry and holds multiple sensor patents. He can be reached at 864-576-6288, fax: 864-576-0009, email: eric.reber@mahloamerica.com or www.mahloamerica.com.