By Rory A. Wolf, business unit mgr., ITW Pillar Technologies

Abstract

Extrusion coating, lamination and film lamination give rise to complex manufacturing techniques that allow a converter to make high-performance packaging films. The physical properties and the related performance characteristics of composites obtained by extrusion coating & lamination can be comparable to those produced by film lamination. This paper examines how the use of ozone combined with corona discharge compares to ozone combined with atmospheric plasma relative to seal strength for these composite-film constructions and suggests a direction for future improvements in seal strength.

Introduction

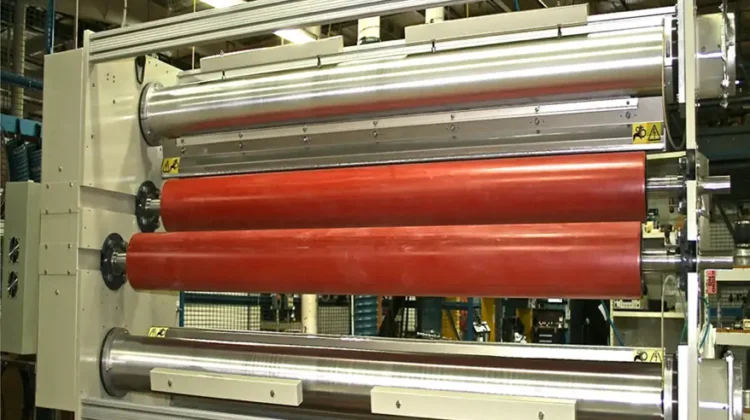

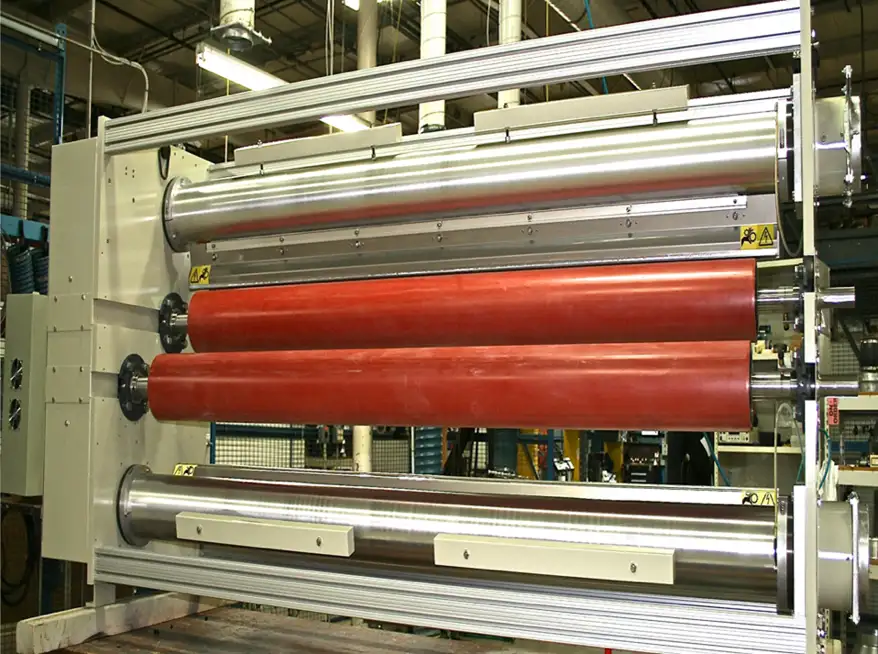

In extrusion coating & laminating, the resin, melted and formed into a thin hot film, is coated onto a moving substrate such as paper, paperboard, metal foil or a plastic film. The coated substrate then passes between a set of counter-rotating rolls, pressing the coating onto the substrate for complete contact and adhesion. A coating-extrusion system is shown in Figure 1.

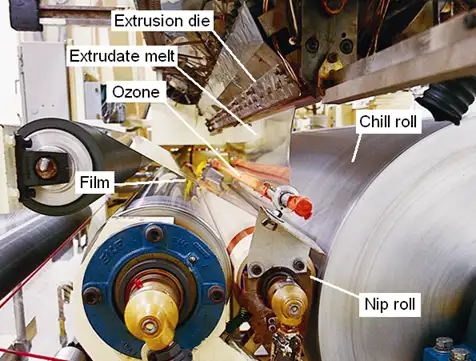

The extrusion lamination, or sandwich lamination, is a process related to extrusion coating. In this case, the extrusion-coated layer is used as an adhesive layer between two or more substrates. A second layer is applied to the extrusion coating while it is still hot, and then the sandwich is pressed together by pressure rolls (see Figure 2). In film lamination, a fabricated film is adhered to a moving substrate by application of heat and pressure. Film lamination includes several methods with different combinations of heat and pressure to ensure adhesion.

Examples of common composite films are the materials for drink-pouch stocks and composites for the medical-packaging industry. The typical beverage-pouch stock is a combination paper/PE/foil/PE, while the material used for medical packaging usually consists of PET/PE/foil/PE. These materials then have four substrates and three interfaces among substrates, sometimes with adhesives or primers used at the interfaces. Converters can laminate the four substrates by means of three separate operations, or the layers are combined in extrusion laminations. In fact, the polyethylene layer can be inserted in the combination by means of a coating extrusion from PE pellets or with a laminating process of a PE film.

Modifying interfaces

A major factor influencing the extrusion bonds is the specific adhesion; that is, the capability of the molten polymer to conform to or match the chemical composition of the substrate. In the examples mentioned above – for instance, that of the composite polyester/PE/foil/PE used for medical packaging – the actual construction to consider is more likely polyester/interface/PE/foil/PE. At the polyester-polyethylene interface, a primer, an adhesive and/or surface modifications are necessary so the polyester will adhere properly to the PE. Likewise, a surface pretreatment between the foil and PE is necessary to form a sufficient bond between those two substrates.

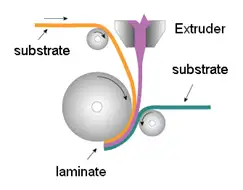

Application of surface modification to a substrate before an extrusion-coating or extrusion-laminating operation requires combinations of corona, flame, ozone and atmospheric-plasma equipment to optimize adhesion (see Figure 3), (a combination of ozone and surface treatments). In some instances, a chemical primer or an adhesive layer is used to improve lamination. A detailed discussion on the role of primers in extrusion lamination was provided by PFFC Editor David Bentley in his paper on primers.

Choice of surface modification technique

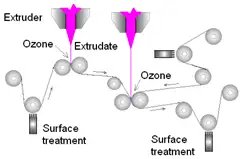

The corona discharge, particularly bare-roll and universal-roll designs and flame treatment at atmospheric pressure, have been effective for improving adhesion of various substrates on extrusion coating lines (Figure 4 shows a multilayer system). The more recent variable-chemistry, atmospheric-plasma treatment (APT) has proven to be able to significantly promote covalent bonding of coatings to substrate surfaces.

Let us consider, for instance, the coating with LPDE. To have adhesion, it is necessary to provide oxidation of the nonpolar plastic material. For molten plastic to oxidize, high temperature and contact with air are required. And in fact, nonpolar LDPE oxidizes at high temperatures (300-330º C) in the extrusion-coating process. But excessive oxidation caused by running at low speed and high temperatures can promote odor and taste problems for the product contained in the packaging. For this reason, extrusion coaters and laminators seek to use lower process temperatures without special resins or chemical priming of the substrate. A common way to accomplish this is to blow ozone (O3) directly onto the molten plastic, thereby oxidizing it. However, the influence of ozone on different plastics together with various surface-modification techniques, such as corona and atmospheric plasma, has not been quantified by exhaustive experimental data, and it is still then an open research problem.

Extrusion coating experiments

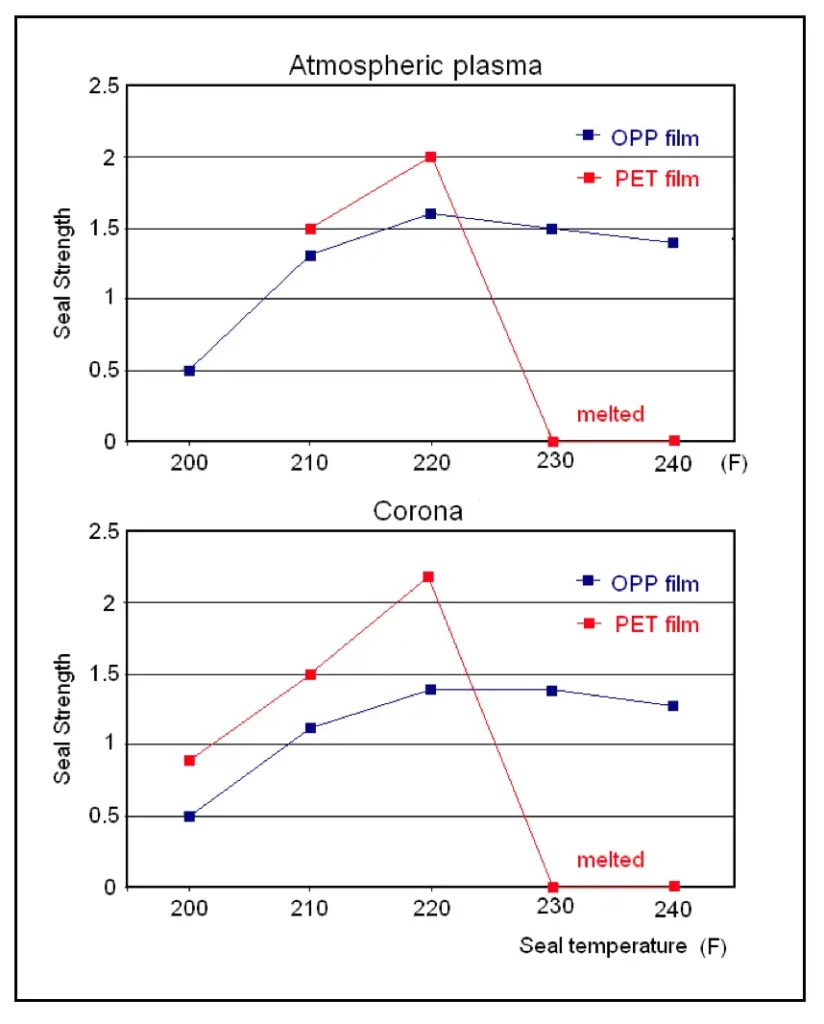

The analysis of a process such as extrusion coating & laminating is rather complex. Here, we discuss only the role of the surface treatments in these coating processes, reporting some results obtained comparing ozone/corona with ozone/APT treatments. In particular, two experimental runs were performed by coating LDPE onto OPP and polyester film. Ordinary heat-seal strength techniques were used to quantify the effects of the variables on heat-seal strength vs. seal temperature.

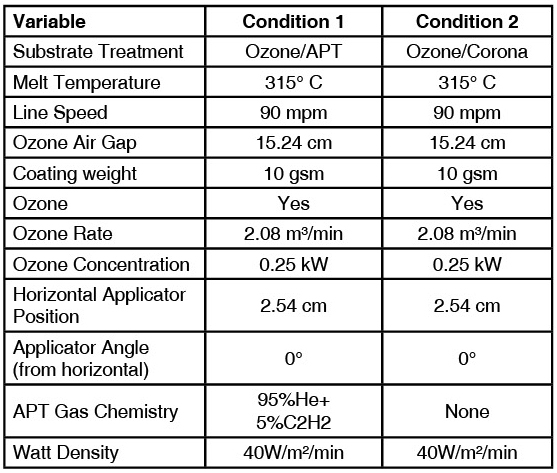

Including atmospheric-plasma treatment, five variables are thought to affect adhesion and heat-seal strength, namely substrate surface modification, melt temperature, line speed, air gap and coating weight. Besides these factors, several ozone-related parameters were identified that could affect adhesion and heat-seal strength. These parameters were ozone flow rate, ozone concentration (power setting on ozone unit) and geometry of the applicator setup (such as horizontal distance and angle from horizontal). The levels used in this design are shown in Table 1, accomplished by a combination of oxidation of the extrudate and treatment of the substrate. The level of oxidation is a function of the melt temperature, line speed, air gap and coating weight. Some combinations of these variables will yield acceptable adhesion but also produce undesirable effects, such as increased taste and odor problems or poor heat-seal strength.

The atmospheric-plasma trial runs were performed on an APT pilot line. The extrusion-coating trial runs were performed on the Equistar Millennium Petrochemical extrusion-coating pilot line. For all extrudate runs, an LDPE (Melt Index 10, 10 g/10 min) was coated onto OPP and PET film. The samples were prepared and tested according to ASTM Test Method F88 (see Figure 5). Heat-seal tests were made on a heat-seal machine using a pressure: P = 206.8 kPa and a dwell time T = 1 s.

Conclusion

Because the effectiveness of melt temperature on heat-seal strength is much greater at higher air gaps and lower line speeds when using ozone/corona treatments, such adjustments also may improve the heat-seal strength results of atmospheric plasma. Further enhancement of the heat-seal strength can be obtained by optimizing the protocol of APT combined with ozone.

References

- Tietje, A., Fifteen Years of Ozone Treatment in Extrusion Coating, 1987 TAPPI PLACE Conference, TAPPI PRESS, Atlanta, p. 221-224

- Sherman P.B, The Benefits of Ozone in Extrusion Coating, 1996 TAPPI PLACE Conference, TAPPI PRESS, Atlanta, p. 93-99

- Hosmer, D.W. and Lemeshow, S., Applied Logistic Regression, John Wiley & Sons, New York, 1989, p. 1-23

Rory Wolf, business unit mgr. for ITW Pillar Technologies (Hartland, WI), is a recognized industry resource in the field of polymer surface modification with 30+ years of industry experience. He holds a BBA with emphasis in Finance/Marketing from the University of Wisconsin-Milwaukee and an MBA with emphasis in Finance/Marketing from Marquette University. Wolf has published 35 technical papers, 41 industry articles and three books on the topic of plastic surface modification by atmospheric-plasma technology. He is active with AIMCAL, TAPPI and SPE, among others. Wolf can be reached at 262-912-7212, email: rwolf@pillartech.com, www.pillartech.com.