Labels and packaging are no longer just functional; they are critical components of brand strategy, product differentiation and environmental responsibility.

By Linnea Keen, president, TLMI

In today’s fast-paced consumer-driven world, the label and packaging industry plays a crucial role in not just product presentation but also in sustainability, brand identity and consumer safety. The label and packaging industry has demonstrated its ability to be agile during the pandemic and unprecedented demand while weathering global supply-chain issues. The stock build of 2023 and its ramifications appear to be in the rear-view mirror for the industry, thus product lead times and demands are normalizing.

The focus of the label converter printers and their suppliers has shifted to managing their businesses, costs, internal operational efficiencies and revenue growth, while adjusting to the change in consumer behavior and preferences. Inflation has impacted consumers. They are spending more and buying less, plus they have shifted from premium brands to private label or store brands to save money at the grocery store. This shift sends ripples through the industry, impacting market segments and verticals. It results in changes in label type, material used, run length and many other factors. The industry daily demonstrates its agility by how it continues to adjust to the ever-changing landscape.

While the industry is experiencing changes in consumer behavior and preferences, which result in changes in labels and packaging, this rapid transformation is coupled with technological advancements, normalizing demand and regulatory pressures across different markets and individualized states. Labels and packaging are no longer just functional; they are critical components of brand strategy, product differentiation and environmental responsibility.

Advancements in technology in label printing

Digital printing revolution

Digital printing continues to evolve and improve its speed and capabilities. As a result, it has revolutionized the label industry by offering shorter print runs, customization capabilities and quicker turnaround. This technology allows brands to personalize labels and packaging, thus responding swiftly to market demands while enhancing consumer engagement. Consumer behavior has shifted due to inflation but also due to digitalization, i.e. digital consumer ads. Private small brands have grown significantly as a result of digitalization, leading to personalization and smaller orders and runs. This is a perfect fit for digital printing.

Advances in flexographic printing yield efficiency gains

Flexographic printing remains the dominant print technology in label production due to the significant installed base and infrastructure in place. Flexographic printing is continuously evolving with improvements in print quality, efficiency and sustainability. Innovations such as water-based inks and advanced plate-making technologies have reduced environmental impact while maintaining high print standards. Label printers are investing in digital printing to enhance their capabilities and offer more to customers. This adds complexity to their operation and raises the need to invest in platform production systems to drive efficiency in their operations.

Automation and AI are priorities for business owners and leaders. Investment in automation is a priority not only for operational gains in efficiency but also as a means to managing through workforce challenges. Low unemployment and lack of qualified workers have driven investment in automation, and it will continue.

Artificial intelligence was a hot topic at our recent annual Converter Meeting and will be a session at TLMI’s upcoming Annual Meeting. Many leaders and owners are trying to understand how to incorporate AI into their business strategy and operations. It will be important to learn from one another and share experiences and insights. It is a technology that will bring tremendous benefit, but there will be a steep learning curve first.

Other trends shaping the packaging industry

Alternative packaging solutions

It is all about shelf appeal for the brands to influence consumer buying behavior. There are several packaging solutions to meet the needs of the brands, which include pressure-sensitive label, cut and stack label, in-mold label and shrink sleeve label. Package-decoration technologies have expanded to offer more eye-catching enhancements and embellishments.

Growing label and packaging solutions are linerless label, narrow-web flexible packaging, Smart Labels and RFID Technology. Linerless labels are a solution that is based on the application and fit for purpose. Narrow-web flexible packaging is growing to meet the needs of CPG companies to offer their products in convenient packaging with a stable shelf life and appeal.

Smart labels equipped with RFID (Radio-Frequency Identification) and NFC (Near Field Communication) technologies enable brands to track products throughout the supply chain, enhance inventory management and provide consumers with interactive experiences. These technologies are transforming how brands engage with consumers and manage logistics. These technologies also assist in authenticating products, traceability and origin of products.

Sustainable packaging solutions

The shift toward sustainable packaging solutions continues to be a defining trend in the industry. Consumers increasingly favor brands that demonstrate environmental responsibility through recyclable materials, biodegradable packaging and reduced carbon footprints. Packaging manufacturers are responding by innovating with eco-friendly materials and adopting circular-economy principles. Many states are implementing Extended Producer Responsibility, which will have an impact on the industry and the materials used in labels and packaging. Sustainable product changes will have a positive impact with mandatory recycling targets, reporting and restrictions on single-use plastics. One high-profile product change is the elimination of PFAS in materials, inks and coatings. The suppliers of films, inks and paper products to the industry invested significantly to ensure that their solutions meet the performance requirements of the applications.

E-commerce packaging challenges

The rise of e-commerce has presented unique challenges for packaging design and logistics. Brands must ensure that packaging is durable enough to withstand shipping while minimizing material usage and optimizing pack-to-product ratios to reduce transportation costs and environmental impact. A challenge that the North American market faces is the import of materials that do not meet the standard or function in the application.

Challenges facing the industry

Cost pressures and economic uncertainty

Fluctuating raw material prices, supply-chain disruptions and economic uncertainties pose significant challenges for packaging manufacturers. Companies must adopt cost-effective strategies while maintaining product quality and sustainability standards. Consumers are spending more and buying less, this trend is forecasted to continue.

These challenges are not new to the industry. Business leaders will employ cost-management strategies and optimize operations to deliver on their promises to their customers and investors. This will bring an opportunity for advancements in technology and innovation.

Workforce opportunity

The rapid pace of technological innovation requires packaging professionals to continuously update their skills and embrace digital tools. Bridging the skills gap and investing in workforce training are essential for leveraging new technologies and staying competitive. The changing generational demographic in the workplace will aid in navigating this change and provide new solutions for companies and enhance their customers’ experience.

Future outlook

The label and packaging industry is poised for further transformation driven by advancements in digital printing, sustainable practices and consumer-centric innovations. Key areas of focus include:

Operational excellence: Companies will continue to invest in automation and equipment to expand their portfolio of capabilities to serve their customers and brands. This will lead to improved efficiencies and more complexity in the operations. The use of technology will provide solutions to manage that complexity.

Personalization and customization: Brands increasingly will use digital-printing technologies to create personalized packaging and enhance consumer engagement.

Circular economy initiatives: Adoption of recyclable materials, sustainable packaging and closed-loop systems will accelerate as brands strive to achieve sustainability goals.

Smart packaging: Integration of Internet of Things technologies and interactive packaging solutions will provide consumers with real-time information and enhance brand loyalty.

In my recent conversations with our members about the market and the future, many are optimistic. Historically, industry has been very predictable and cyclical. Post-pandemic, that has changed. When I asked them about the current market trends, responses ranged from very busy to it is stable, and most said it depends. It depends? It depends on which market you are servicing, who your customers are and on what market you are in. For example, if you are in e-commerce, nutraceuticals, pharmaceuticals and wellness, the demand continues to be strong. If you are in promotional products, transportation, automotive and durable goods, those markets struggled during the pandemic, but the demand is strong now.

The markets that seem to be the most impacted are food and beverage-related. While the demand still is exhibiting growth, the changes in consumer behavior are more visible. Trends that are prevalent are shifts to private label and store brands, lower alcohol consumption, increased craft-beverage demand, dining out vs. eating in and use of weight-loss drugs that result in lower food consumption. These are just a few that were noted. Many cited investing in their operations and their employees.

As the label and packaging industry evolves, stakeholders must navigate a complex landscape of technological innovation, regulatory requirements and shifting consumer expectations. Embracing sustainable practices, leveraging digital technologies and fostering collaboration across the supply chain will be crucial for achieving long-term success and meeting the demands of a dynamic market.

This is a resilient industry that continues to grow. The growth rate is higher than GDP and varies based on the market and label and packaging technology. It always has been and continues to be an exciting industry to be a part of. The future is bright.

Conclusion

While challenges abound, the label and packaging industry’s commitment to innovation and sustainability promises a future where packaging not only protects products but also enhances consumer experiences and preserves the planet for generations to come.

More info: www.tlmi.com.

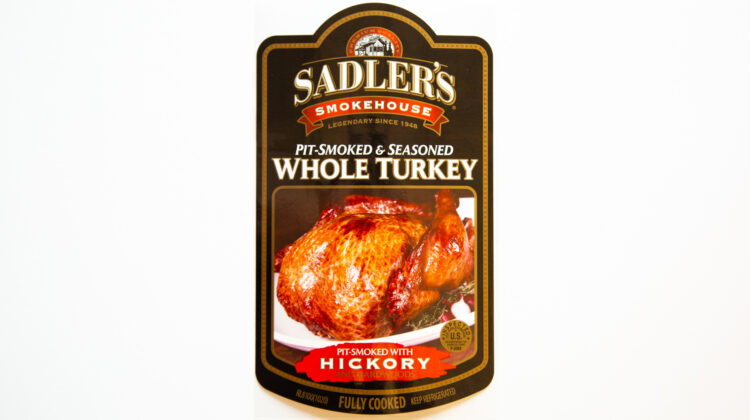

Photo: The Sadler’s Smokehouse Whole Turkey label, printed by McDowell Label, a Resource Label Group company, took First Place in the Food Category in the 2023 TLMI Printing Excellence Awards.