Michigan-based Dürr Systems AG has received a significant order from Italian battery manufacturer FIB S.p.A, a Seri Industrial Group company. Awarded in December 2024, the order includes a giga-coating system comprising four anode and four cathode lines, as well as associated calenders, slitters, and solvent-recovery systems. The order value is in the upper double-digit million-euro range.

The order result from a strategic intensification of activities in battery production, which Dürr began in 2018 with the acquisition of the US company Megtec/Universal. With its coating, drying and solvent-recovery systems, Megtec brought solutions for three key steps in lithium-ion battery production. In 2020, the partnership with Japanese coating-equipment manufacturer Techno Smart Corp. was established. The acquisition of Ingecal in 2023 brought a specialist in calendering technology into the company.

From January 2025, Dürr’s coating business operates in the new Lithium-Ion Battery business unit. FIB S.p.A., active in the production of lithium-iron-phosphate batteries, is investing in a competitive, technologically advanced battery-production facility in Europe, using innovative, predominantly Western technology.

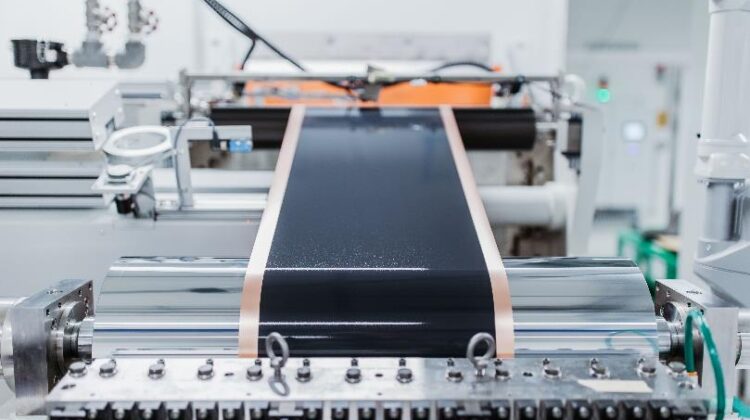

The equipment supplied by Dürr includes the tandem coater, a proven system that sequentially coats the foil on one side and then the other. Other sections include the webline, dryer, calender, slitter and solvent recovery for the anode and cathode areas. The plant’s capacity at full load, based on the FIB cell and capacity design, is expected to be 8 GWh/year.

The schedule for the two-phase project near Naples is tight, with installation to begin in fall 2025 and production to start in 2026. “Particularly noteworthy is the short time from receipt of the order to the start of installation of the first lines in just 10 months – after all, the ink is only just dry,” says Bernhard Bruhn, vp-Global Business Unit Lithium-Ion Battery at Dürr.