By Hanze Ying1, Bernhard Kainz1, Marc Black2, Christina Sullivan1, Kristen Gracie Carroll1, Hadrien Lenoir1, Joseph Harris2, William Liechty1, Jonathan Mason1, Ray Drumright1

1 Department of Coating Materials, The Dow Chemical Company

2 Department of Core Research and Development (R&D), The Dow Chemical Company

Consumer demand for sustainability-driven solutions is fueling interest and growth in paper packaging, but challenges remain for paper to deliver barrier performance and processability equivalent to incumbent technologies. In this work, we present waterborne-coating solutions that provide barrier and heat-seal/hot-tack properties meeting paper-packaging needs. Strategies enabling waterborne coating products to form good barriers on papers of varying porosity and smoothness are addressed. To simulate a package forming process, a new testing workflow was developed to characterize the processing window for formation of pillow pouches from coated paper, which showed correlation to the coatings’ heat-seal/hot-tack profiles. This work paves the way for use of waterborne barrier coatings in paper packaging applications that deliver desirable performance and function under a wide range of processing conditions.

Editor’s Note: This technical paper is based primarily on the author’s presentation at the Specialty Papers USA conference, held in Milwaukee (WI) in October 2023. More info: www.specialtypaperconference.com/specialty-papers-us

Introduction

Consumer demand for sustainability-driven solutions is fueling interest and growth in paper packaging [1], but challenges remain for paper to deliver barrier and process performance equivalent to incumbent plastic solutions. Due to their porous nature, paper substrates require thin layers of polymeric coating to prevent package contents from leaking or deteriorating [2,3]. The coatings also need to provide heat-sealability that allows the paper to be formed into various packaging types under temperature/pressure.

Coating products cursorily tested in the lab often face challenges when translated to pilot or manufacturing scales due to the lack of performance robustness. Many factors and conditions change across different production scales and process setups, e.g. paper substrate porosity/roughness, coating/packaging forming line speed, heat-seal temperature/time/pressure, etc. A successful and practical coating solution is expected to be adaptable to meet performance targets across a wide range of scenarios.

In this paper, we discuss the development of two laboratory methods to evaluate the robustness of barrier and heat-seal/hot-tack performance of coatings, as well as the use of these methods to optimize product applications.

Experimental materials and methods

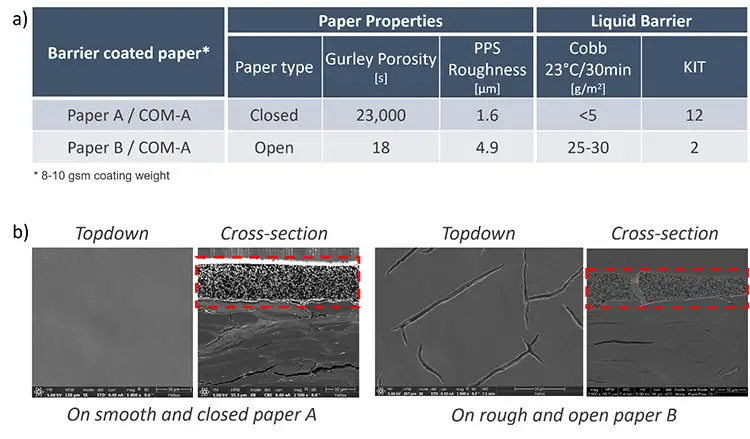

All waterborne dispersions were prepared using a twin-screw extruder-based BLUEWAVETM mechanical-dispersion process [4, 5]. Coating dispersions were applied to either closed (commercially available low-porosity, 62-gsm packaging paper, Gurley porosity: 23000 s/100 mL (following the method based on TAPPI T460), PPS roughness: 1.6 µm) or open paper substrate (commercially available high-porosity, 250-gsm paperboard, Gurley porosity: 18 s/100 mL, PPS roughness: 4.9 µm) with drawdown bars targeting dry coatweights of 8-10 gsm unless otherwise specified. All coatings were cured at 100º C for 2 min before testing.

The water barrier was measured with a “Cobb tester” as water-uptake per unit area represented by gsm at 23° C for 30 min based on TAPPI method T441. Oil/grease barrier was measured based on TAPPI method T559 cm-12 (also named “Kit test”), in which a score rating of 1-12 (12 is the highest performance) was assigned based on the breakthrough of the highest numbered Kit solvent mixture.

The hot-tack curves were characterized by a heat-seal/hot-tack testing system (Enepay MAGMA 3). The hot-tack test followed ASTM F1921 with the following conditions: seal-jaw pressure: 0.5 N/mm, dwell time: 0.5 sec, pull speed: 200 mm/sec, pre-test delay between sealing and pulling: 0.2 sec.

Morphologies of paper coatings were examined using an FEI Nova Nano SEM scanning electron microscope (SEM). For cross-sectional analysis, samples were embedded into epoxy, allowed to cure and then cryo-microtome polished. Samples were then vapor-stained by suspension over solutions of osmium tetroxide and then ruthenium tetroxide.

A laboratory corona treater (DocuDyne Hybrid Corona Treatment Station) was used to treat coated paper with an energy density of 25 watts/(m2×min).

The surface tension of a liquid dispersions was measured by Wilhelmy plate method described in ASTM D133-20; the surface energy of a solid, dried coating was measured by Dyne pen based on ASTM D2578-23.

Enhanced barrier robustness and reduced coatweight with “two-layer” coating approach

One of the challenges in paper barrier-coating design is the variation in paper substrate type. As shown in Figure 1a, the commercial product COM-A showed great barrier performance on smooth and closed paper A, which deteriorated when coated on more rough and open paper B with the same coatweight. The barrier performance correlates with the scanning electronic microscopy (SEM) images, which showed more cracks and defects of coating on paper B (Figure 1b). This issue with the open paper is universal across different coating systems due to the faster loss of water or emulsion/dispersion particles from the wet coating into the porous substrates that hurts the film formation [6]. Therefore, the performance of coatings on open paper becomes an indicator of robustness of a coating’s barrier properties.

One way to improve the barrier performance on open paper is through the approach of a “two-layer coating.” The first layer applied to the bare paper seals off the pores and smoothens the surface, and the second layer covers defects and gives improved film formation. With this approach, coatings can achieve improved barrier performance with the same or even less total coatweight than applied in a single pass. Reduction of coatweight can improve the fiber recycling yield of coated paper, which is a critical part of this sustainable-packaging solution.

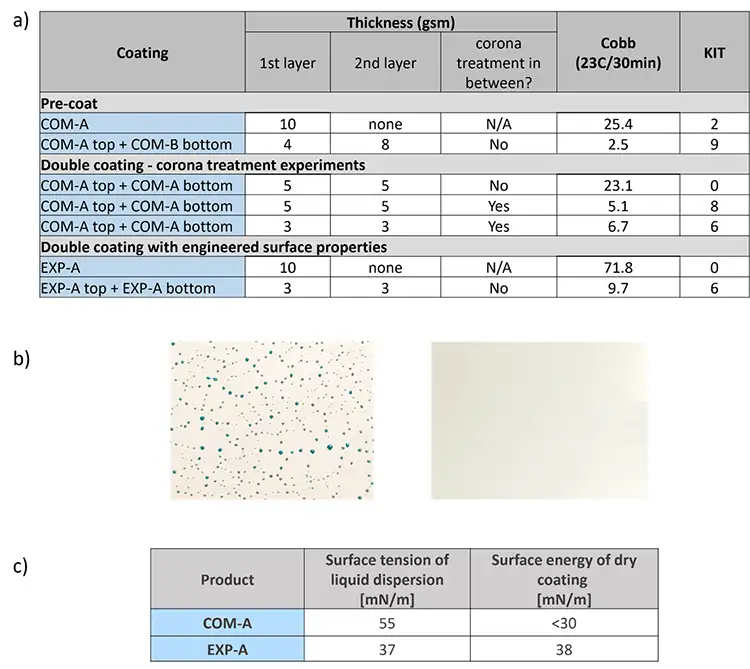

Figure 2a shows an example of the “two-layer” coating approach: One layer of COM-A on open paper at 10 gsm gave a Cobb of 25.4 gsm and KIT of 2. However, with the use of a pre-coat (8 gsm COM B), a significantly lower Cobb of 2.5 gsm and higher KIT of 9 was achieved with only a 4-gsm topcoat of COM-A (12 gsm total coatweight).

Another way to build the two-layer structure is through the application of the same coating twice. This sometimes can be a challenge for waterborne coatings designed for water barrier due to poor recoatability (the second layer tends to de-wet from the first layer) arising from hydrophobicity and low surface energy. Two 5-gsm layers of COM-A showed similar poor performance as compared to the single 10-gsm layer of the same coating. In fact, the wet second layer beaded up quickly when applied to the dry first layer, as shown in the left image of Figure 2b. Corona treatment was found to be a good solution that increased the surface energy of the first layer and improved the surface wetting. With corona treatment, the second layer wets evenly (right image of Figure 2b) and provides a high performing coating at the same (5+5, 10-gsm total) or reduced (3+3, 6-gsm total) coatweight than the single-layer approach.

Another strategy to improve the wetting behavior of a double coating is to redesign the coating compositions to obtain altered surface properties. As shown in Figure 2c, EXP-A is a new experimental prototype with lower surface tension of the liquid dispersion and higher surface energy of dried coating as compared to COM-A. Both changes were expected to improve the wetting behaviors between two layers [7]. As can be seen in the bottom rows of Figure 2a, a second layer of EXP-A easily wets the first dry layer of itself, giving improved barrier performance from the two-layer structure with reduced total coatweight (3+3, 6-gsm) compared to one single layer of 10-gsm coating.

Robustness of coating heat-seal/hot-tack with pouch-forming/leaking test

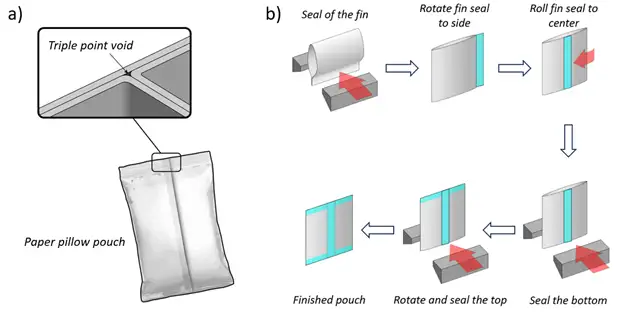

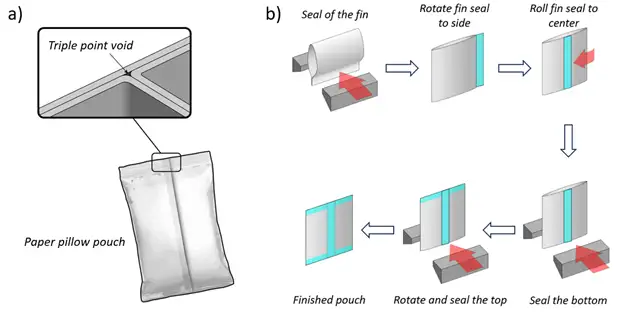

In addition to the barrier performance, the heat-seal/hot-tack properties of coatings also are critical to ensure successful paper-packaging forming processes resulting in good package integrity and hermeticity. Standard lab testing is good for measuring the heat-seal/hot-tack properties between two flat and parallel coated-paper sheets. However, these standard tests do not always reflect the behaviors of real pouch-forming processes, especially the ones with “fin” or “gusset” folding that have “triple point voids” (see Figure 3a).

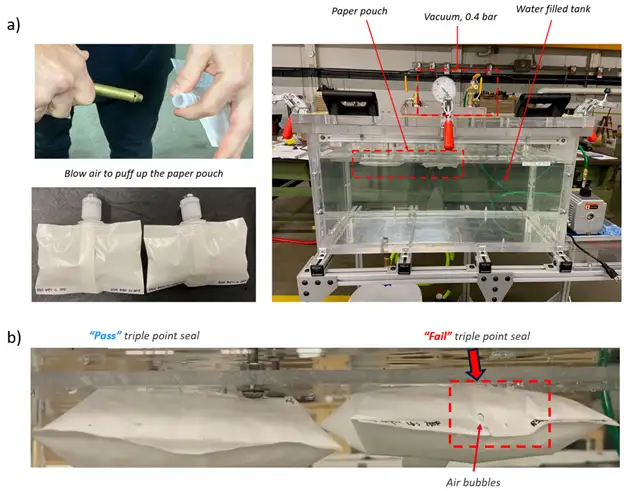

To better mimic the real industrial process, a new lab-testing workflow was developed to evaluate the robustness of coating-sealing performance in a pillow pouch-forming process. Figure 3b illustrates the process to form the paper pillow pouch from a flat sheet of coated paper, which involves multiple steps of fin seals, side seals and rotations. A plastic fitment is installed on one side of the pillow pouch, which allows the inflation and containment of positive pressure that facilitates visualization during leak tests (see Figure 4a, left).

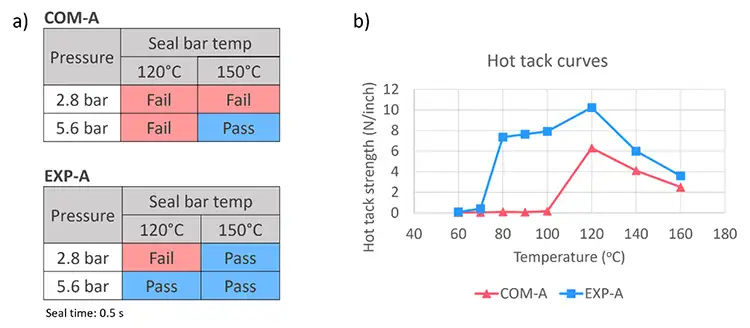

For the leak test, a “fish tank” is set up as a partially water-filled container connected with valves and a pump that pulls vacuum of about 0.4 bar on the headspace. Inflated paper pouches are put into the tank, which float at the top and are pressed down by a plastic mesh-board to ensure full immersion under water. When under vacuum pressure, any pouch leaks are highlighted by a stream of escaping air bubbles (see Figure 4b, right), whereas a well-sealed pouch shows nothing (see Figure 4b, left). With this method, the paper pillow-pouch sealing with COM-A and EXP-A coatings were evaluated at various sealing temperatures and pressures (all with the same sealing time of 0.5 sec and same coatweight of 8-10 gsm on closed paper A).

COM-A coated paper passed the test under the condition with the highest temperature and pressure. Showing more robust behavior, EXP-A passed at three of the four conditions and failed at the condition with the lowest temperature and pressure (see Figure 5a). The results demonstrate that the EXP-A is expected to be a robust coating product for the industrial pillow pouch-sealing process. It is satisfying that the results of the “fish tank” testing is in line with the hot-tack curves collected from flat sheets (see Figure 5b), where EXP-A shows high hot-tack strength with a broad temperature window.

Conclusions

In this work, we presented strategies for applying waterborne barrier coatings to open and closed paper substrates to achieve robust water- and oil-barrier performance. In addition, a new laboratory method for characterization of the quality of heat-sealed pouches from barrier-coated papers was introduced. These strategies and methods are being applied to develop new materials and products that enable sustainable paper packaging.

References

- Mordor Intelligence (2020) “Paper Packaging Market – Growth, Trends, COVID-19 Impact, and Forecasts (2021-2026).” Available at: www.mordorintelligence.com/industry-reports/paper-packaging-market# (Accessed: 26 Feb. 2024).

- Globe Newswire (2021) “Global Barrier Coated Flexible Paper Packaging Market Size – Forecasts to 2026.” Available at: www.globalmarketestimates.com/market-report/global-barrier-coated-flexible-paper-packaging-market-3164. (Accessed: 26 Feb. 2024).

- Holik, H (Ed)., Paper with Barrier Properties, Handbook of Paper and Board, Wiley-VCH, 1st Edition, 2006

- Piwowar A.; Rosen K.; Ellison C.; Mason J.; Katzenstein J.; Einsla B.; and Smith R., “Polyolefin-Based Waterborne Barrier Coatings for Paperboard,” 19PaperCon, TAPPI.

- Katzenstein J., Rosen K., Ellison C., Roper J., and Smith R., “Polyolefin-Based Waterborne Barrier Coatings for Paperboard,” 17PaperCon, TAPPI.

- VÄHÄ-NISSI M., SAVOLAINEN A., TALJA M., AND MÖRÖ R., “Dispersion barrier coating of high-density base papers,” TAPPI JOURNAL, November 1998, Vol. 81(11).

- Prakash J.C.G., Prasanth, R. “Approaches to design a surface with tunable wettability: a review on surface properties.” J. Mater. Sci. 56, 108–135 (2021).

Dr. Hanze Ying is an Associate Research Scientist from Dow Chemical’s Business Research & Development organization. He received his B.S. in Chemistry from the Peking University. Then he earned his Ph.D. in Materials Science and Engineering from the University of Illinois at Urbana-Champaign, developing a new type of dynamic covalent chemistry named “hindered urea bond” for smart materials design. With Dow, he developed expertise in mechanical dispersion-derived coating materials for various sustainable industrial solutions in paper packaging, metal beverage/food packaging, lamination adhesive, etc. He has authored 19 peer-reviewed publications and nine patents. Dr. Ying can be reached at 989-636-4636, email: hying@dow.com.

Dr. Bernhard Kainz is Principal Scientist at Dow Coating Materials. He received his B.S., M.S., as well as his Ph.D. in Chemistry from the University of Stuttgart in Germany, and his M.Ec. from the University of Hagen, Germany. During his long career, he has driven technology development of epoxy resin coatings for packaging and general metal-coating applications and spearheaded the development of waterborne mechanical-dispersion technology into packaging-coating applications. He is engaged in multiple industry associations including metal and fiber-based packaging. He has authored more than 20 patents and multiple publications as well as conference presentations.

Marc Black is a Research Scientist from Dow’s Materials Engineering Center (MEC), part of Core Research and Development. Marc is also an Industrial Designer with over 30 years of experience and is a focal point for Additive Manufacturing. In his role as a leader in front end innovation, Marc supports a variety of programs and businesses using Design Thinking tools. He has authored 30 papers and has 22 patents in his career.