By Edward D. Cohen, Ph.D., president, Edward D. Cohen Consulting, Inc.

Guidelines are the specific information intended to advise coating personnel on how to operate the specific process element with which they are involved. Part 1 of this paper presented the first of several functional elements, from R&D to scale-up. The next sections will cover the remaining elements, from selecting a coating method and general coater operation to waste management and technical information.

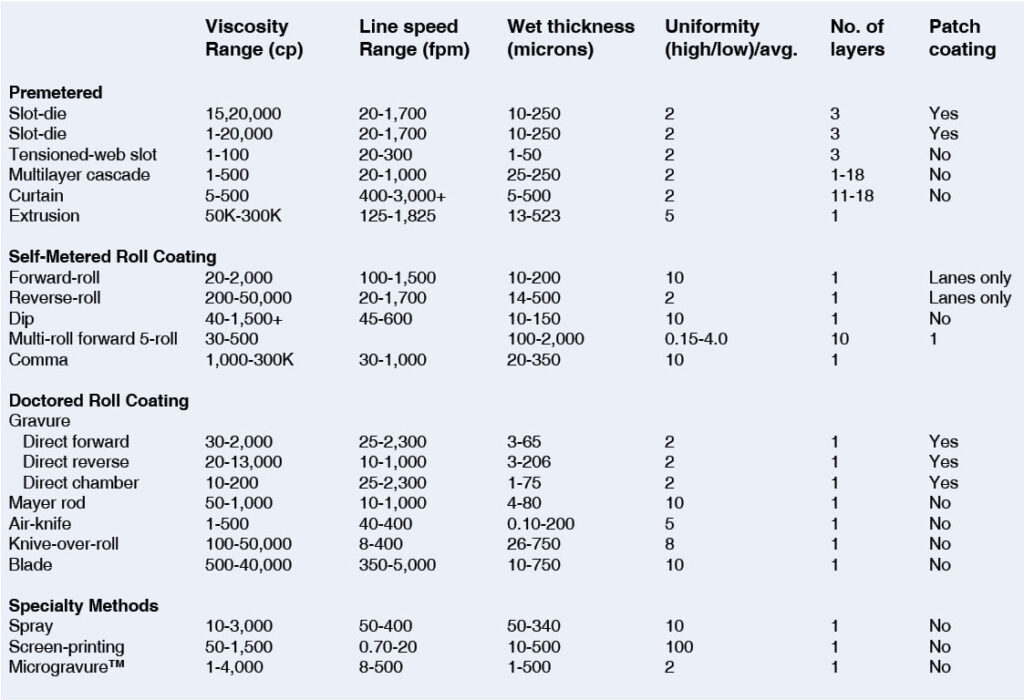

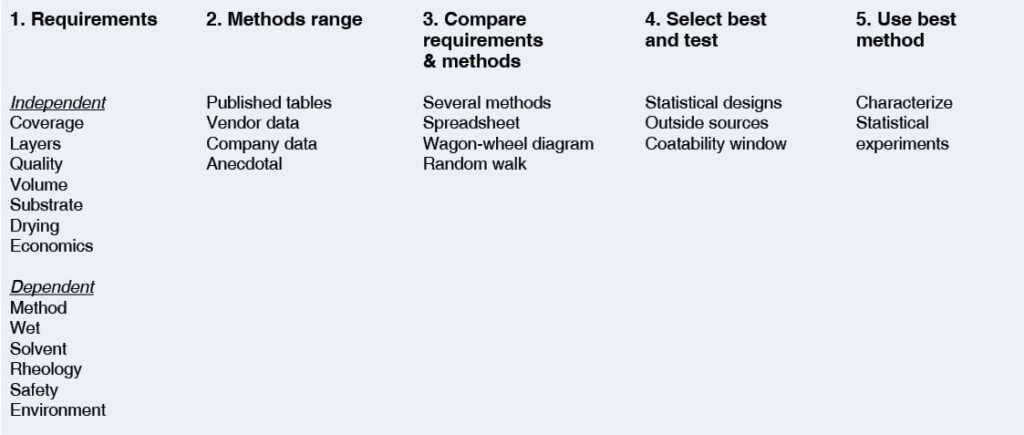

Coating method selection: No single coating method can coat all possible solution requirements, wet-coating thicknesses, solution viscosity, coatweight uniformity or line speed. This can be seen in Table 4, which shows the distinct operating ranges for several widely used coating methods. Therefore, the coating method chosen must meet the specific requirements of the product. Table 5 describes the five-step procedure to select an appropriate coating method.

Sources: Cohen, E.D., and Lightfoot, E.J., “Coating Processes.” Kirk-Othmer Encyclopedia of Chemical Technology, p. 1-68; Cohen, E.D., and Gutoff, E.B., “Coating Process Survey,” Kirk-Othmer Encyclopedia of Chemical Technology, fifth edition, John Wiley and Sons, Inc., New York, 2002.

General coater operation: A typical web-coating line may include all the necessary process modules listed in Figure 6. Specific guidelines for efficiently operating the coater are:

- Use and maintain Standard Operating Procedures (SOPs) for all hardware and product coating and drying conditions.

- Train operators in SOPs, safety and operating all components.

- Maintain coating applicators and all coater components.

- Ensure the coating line and coating building are clean.

- Control air quality and ambient conditions in the coating building.

- Record all process data in easily available databases.

Solution preparation: The solution-preparation process uniformly mixes the raw materials using the appropriate high shear rate or low shear mixers. The sequence of raw-material addition, mixing time, temperature, filtration and cleaning of kettles is critical to ensure uniform solutions or dispersions.

Solution delivery: The solution-delivery system transports the coating solution from a holding kettle to the applicator. Its functions include:

- Maintain a uniform reproducible flow rate to the coating head.

- Remove all air bubbles and contaminants that could result in coating defects.

- Maintain a uniform solution temperature and viscosity.

Coating application: The coating solution is delivered to the applicator, which then applies the solution to the substrate. Key factors in this step are:

- Use the appropriate coating method.

- Keep a uniform flow rate of coating solution to the applicator.

- Maintain a reproducible solution rheology and applicator setting during coating.

- Keep a clean coater and coating station.

- Understand that higher flow rates give better quality and coating-application stability.

Drying & solidification: After the wet coating solution is applied, it must be solidified by removing the solvent or cooling the coating if it is a hot-melt coating. The drying air is delivered to the wet coating by a variety of nozzle configurations. The air must be contaminant-free, of a uniform temperature and be uniformly delivered to the wet coating so it dries evenly. The transition temperatures (Tg, Tm, Td ) of the substrate should be known so the substrate does not deform or decompose in the dryer.

Quality control: QC procedures for the web-coating process are a system of measurements intended to ensure the quality of the coated product is achieved and also reproduced in each future production campaign. Customers must receive material that functions as intended and has no defects that impair its use. Important considerations are analytical instruments that can accurately measure solution and coated-product requirements. On-line coating quality and defect-inspection systems are very effective and should be used on all coating lines.

Roll storage: Storage conditions of the uncoated substrate and finished, coated-product rolls must be maintained so the performance properties and overall roll quality are not damaged. This requires controlling ambient-air conditions in the storage facility at a temperature and relative humidity that, for example, does not cause rolls to stick when moisture penetrates the material. If there is a significant temperature difference between storage conditions and coating-room air, raw-material rolls should be held at coater conditions so they can adjust before they are opened for coating. For instance, a cold roll in a high-humidity room can lead to moisture condensing on the material. Storage-area air also should be relatively free of particles that could deposit on the substrate. In addition, heavy rolls can sag under their own weight on the storage racks. This can be avoided by rotating the rolls at fixed time intervals.

Waste management: As much as any web converter can try, the coating process is not perfect, and a variety of causes results in waste materials, be it uncoated substrates, defective coated webs, or waste solutions and dispersions. Safe, efficient disposal methods for these materials must be established and maintained. These include collection and storage capability in the laboratory and at the coating line. Recycling of waste should be considered where appropriate. When formulating new products, ease of disposal should be considered when selecting raw materials.

Technical information: Web coating obviously is a high-technology process, and it is essential to understand (and potentially use) all previously well-developed technology and current technologies available. This results in a process being continually competitive and cost-efficient. Additionally, this technical information can help develop and troubleshoot any web-coating problems. Readily available sources include coating-hardware and raw-material vendors, university research programs, technical organizations (AIMCAL, TAPPI), trade journals (Converting Quarterly), Blogs, Webinars and, of course, online searches. Some traditional sources, such as technical books, are listed in the References below.

Finished-product customers also are a source of product-performance information, and their data should be obtained and disseminated.

The R&D, scale-up and manufacturing process, and data for each product should be saved in an easily accessible database that is available for all personnel when needed. It often is much more effective to spend 30 minutes searching all available literature for a solution to a problem than it is to plan and run several laboratory-coating experiments without any background information.

References

Cohen, E.D., and Lightfoot, E.J., “Coating Processes.” Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons 2011.

Cohen, E.D., and Gutoff, E.B., Coating and Drying Defects Troubleshooting Operating Problems, second edition, John Wiley & Sons, New York, 2006.

Cohen, E.D., and Gutoff, E.B., “Modern Coating & Drying Technology,” VCH Publishers, New York, April 1992.

Greener, J., Pearson, G., and Cakmak, M., “Roll-to-Roll Manufacturing: Process Elements and Recent Advances,” John Wiley & Sons, 2018.

Shepherd, F., Modern Coating Technology Systems, Emap Maclaren, Ltd., UK, 1995.

Smith, R.D., The Ultimate Roll and Web Defect Troubleshooting Guide with Glossary, TAPPI Press 2013.

Evans, D.F., “Fundamentals of Interfacial Engineering,” Wiley-VCH, New York, 1997.

Tracton, A.A., “Coating Technology Handbook,” third edition, Marcel Dekker, New York, 2005.

Wagner, J.R., “Multilayer Flexible Packaging,” Elsevier, second edition, 2016.

Edward D. Cohen, Ph.D., president of Edward D. Cohen Consulting, Inc. (Fountain Hills, AZ), has expertise in the coating and drying of thin films, coating-process development and scale-up, film-defect mechanisms and analytical-characterization techniques. With 45+ years of experience in coating research, Cohen is the author of several books. He is an AIMCAL technical consultant, writes the “Coating Concepts” Q&A technical column for this publication and moderates the online Web Coating Technical Topics Channel. Cohen can be reached at 480-836-9452, e-mail: cohened146@aol.com.