In the US, we are familiar with safety approval agencies like UL, ETL and IECEx, and others. At some point, readers might have encountered a product labeled with an ATEX approval and wondered what exactly it meant. In industries such as printing, where flammable atmospheres or combustible dust are present, safety is paramount. ATEX, short for “Atmosphères Explosibles,” is a certification framework established by the European Union to ensure equipment and protective systems used in explosive environments meet strict safety standards. These approvals are not just a legal requirement in many jurisdictions but are critical to protecting lives, assets and the environment.

This article explores what ATEX approvals entail, the risks associated with counterfeit certification labels and the importance of maintaining up-to-date approvals.

What are ATEX approvals?

ATEX certifications originate from two directives set forth by the European Union:

1. Directive 2014/34/EU (also known as ATEX 114): Governs equipment and protective systems intended for use in explosive atmospheres.

2. Directive 1999/92/EC (ATEX 153): Focuses on improving the safety and health of workers in hazardous environments.

For manufacturers, the key focus lies in compliance with Directive 2014/34/EU. This directive ensures that products have been rigorously tested to verify their safety under potentially hazardous conditions. Certified equipment will feature a label indicating compliance, with symbols and codes specifying the product’s classification, intended environment and level of protection.

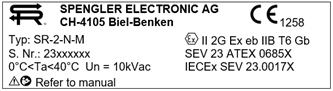

Decoding the label

Every ATEX-approved product includes a label with critical information.

- CE Marking: Indicates conformity with EU directives

- Identification number: 4-digit number following the CE marking that identifies the notified body responsible for the certificate.

- Explosion Protection Symbol (Ex): Highlights that the equipment is designed for explosive atmospheres

- Equipment Group and Category: Identifies where the equipment can be used

- Temperature Class: Specifies the maximum surface temperature the equipment may reach

A sample of an ATEX label (courtesy of Spengler Electronics Ag) is shown in Figure 1.

This labeling is a guarantee that the equipment has been tested and certified according to ATEX standards. However, as demand for certified products increases, counterfeit labels have become a growing concern.

The threat of counterfeit labels

Counterfeit ATEX labels undermine safety and compliance. Fraudulent certifications may appear legitimate, often mimicking the look and feel of genuine approvals. However, these fakes often represent products that have not undergone proper testing. Using such equipment can lead to catastrophic consequences, including explosions, injuries, insurance disclaimers and costly fines for non-compliance.

To ensure the legitimacy of ATEX certification, the following steps can be taken:

1. Verify Certification Numbers: Cross-check the certification number with the issuing notified body or the EU’s public databases.

2. Work with Reputable Suppliers: Source equipment only from manufacturers or distributors with proven track records.

3. Ask for the full documentation: Full documentation includes:

- Operating instructions

- CE declaration of conformity

- Current type examination certificate (see Figure 2).

- Valid ATEX quality management certificate (see Figure 3).

If there is any doubt about a product’s certification, consult the notified body responsible for issuing ATEX approvals to confirm its authenticity.

Why current approvals matter

Equipment certifications are not static. Changes in manufacturing processes, materials or safety regulations can render older certifications obsolete. Therefore, equipment must be regularly re-evaluated to meet updated safety requirements.

Keep approvals up to date

There are several reasons to keep approvals up to date.

1. Compliance with Evolving Standards: Safety regulations periodically are revised to address new risks or incorporate advances in technology. Outdated certifications may no longer meet current requirements.

2. Insurance and Liability Risks: Using equipment without current certifications can lead to denied insurance claims or legal liability in case of accidents.

3. Assurance of Safety: Up-to-date certifications provide peace of mind that equipment has undergone the most recent safety testing and is fit for its intended purpose. For facility operators, periodic audits and inspections are essential to ensure all equipment remains compliant. Proactively replacing or upgrading equipment as regulations evolve is a best practice that protects both employees and business operations.

Conclusion

ATEX approvals play a crucial role in ensuring the safety of equipment used in hazardous environments. Understanding how to identify genuine certification labels and the importance of keeping approvals current is critical for compliance, risk mitigation and safeguarding lives. By staying vigilant and informed, companies can ensure they are not only meeting regulatory requirements but also fostering a culture of safety and responsibility.

Alison Crawford

224-358-3085

Alison@midwestprintsolutions.com

CEO of Midwest Print Solutions LLC