Edited by Managing Editor Dianna Brodine

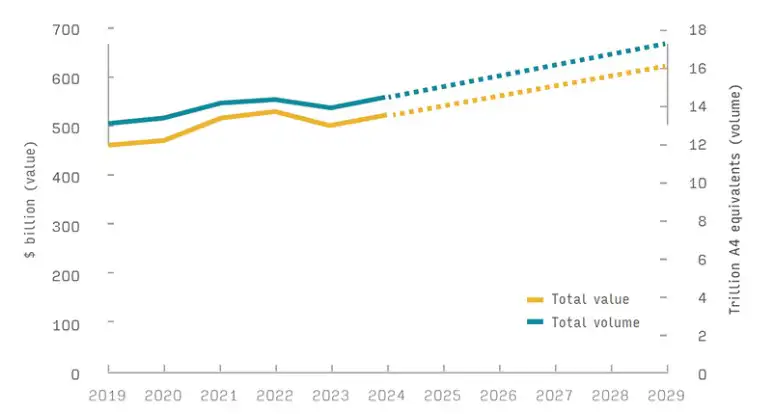

Packaging and labels are increasingly important to the strategic future of the printing industry, with annual sales now worth more than half a trillion dollars, according to The Future of Package Printing to 2029 from Smithers.

While traditional publication and graphics markets are static or in decline, rising consumption of packaged goods is fueling growth. This was witnessed at drupa 2024, with multiple OEMs debuting new machines for printing corrugated board, folding cartons, flexible packaging and labels.

Steady growth for packaging

The report’s market modeling shows that in 2024 total global value in the sector will reach $504.9 billion (constant 2023 pricing). This will see 14.31 trillion A4 print equivalents of labels, corrugated board, folding cartons, flexible paper and plastics, rigid plastic and metal packaging printed this year, consuming 1.54 million tons of ink.

Despite global economic challenges and new sustainability mandates, a steady growth trajectory is reasserting itself. This will push global value to $604.0 billion in 2029, representative of a +3.6% compound annual growth rate (CAGR), by value. Across the same five years, output will increase to 17.12 trillion A4 equivalents (see Figure 1).

Flexo accounts for most print output

Both digital and analog press makers are developing technology to address opportunities across this market. Flexo remains the most widely used print process, especially for high-volume corrugated board, labels and flexible formats. It accounts for 52.6% of contemporary output. Gravure and offset litho also are popular, mainly for printing higher-quality graphics on folding cartons and flexible packaging. These account for 20.1% and 17.9% of packaging and labels volume, respectively, according to the study.

For all analog OEMs, the further penetration of digital print, especially the latest generation of higher throughput inkjet machines poses a direct challenge. Quality is improving on inkjet and electrophotography (toner) presses, even as they become more cost-competitive for longer print runs. These also offer much shorter turnaround times, less wastage, give greater scope for customization and are easier to integrate with online design and ordering systems.

Digital technology asserts itself

At drupa 2024, a host of new machines for high-speed digital printing of folding cartons was shown. There also is a developing footprint of single-pass inkjet corrugated presses, and narrow-web toner and inkjet machines increasingly are being configured to also take short-run flexible jobs. The potential of these systems to offer added value means that while digital accounts for only 1.1% of volume in 2024, it represents 3.9% of value. Smithers’ modeling forecasts further expansion, with digital output growing at a +12.8% CAGR across the next five years.

In response, analog OEMs are investing in greater automation both in pre-press and on-press, combining this with superior workflow, online maintenance platforms and other software, as well as developing hybrid systems with inkjet stations printing variable-data elements on high-speed analog lines.

As technology evolves across the sector, OEMs and print service providers are adapting to changes in packaging materials. The drive for greater sustainability is pushing converters to use more paperboard and coated paper stocks, as well as thicker monomaterial polymer formats

in flexibles.

Emphasis on recyclability

Regulatory developments, including the EU’s Packaging and Packaging Waste Regulation (PPWR), are emphasizing recyclability. This is creating a demand for packaging printers to switch to water-based inks, invest in better de-inking technology and work with new material sets that are easier to recover at end of life. In the narrow web segment, this is pushing converters to move toward thinner, easier to separate label stocks, lowering ink coverage and minimizing or switching adhesives.

More info: www.smithers.com

European markets embrace flexible packaging: Flexible Packaging Europe

The results of a recent consumer survey on the use of flexible packaging commissioned by Flexible Packaging Europe (FPE) [www.flexpack-europe.org] reveal some interesting trends. The representative survey was conducted by the global market research institute Censuswide in the six major European markets of France, Germany, Italy, Spain, Great Britain and Poland in 2024 and recorded the responses of 6,000 consumers.

According to the survey, European consumers particularly value flexible packaging for its very good protective and preservative properties (46%), its ease of use (45%) and its low weight (42%). Flexible packaging enjoys above-average popularity, particularly among younger consumers and in countries, such as Poland and France. In Poland, a total of 28% of consumers are in favor of flexible packaging, followed by 25% in France.

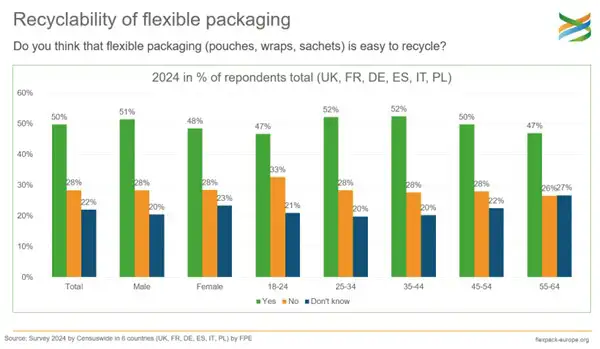

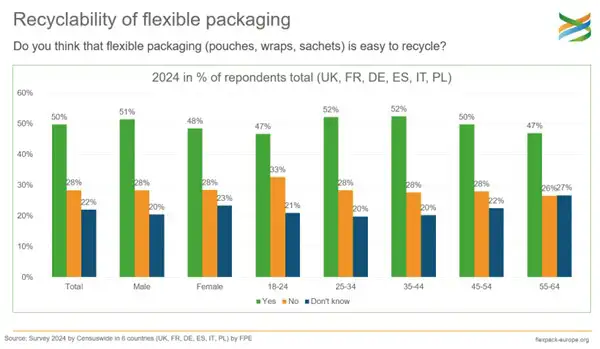

With regard to sustainability, half of all respondents answered that they perceive flexible packaging as recyclable. While there are some differences between countries, e.g. 65% in Spain, 58% in Italy, 40% in Germany and 38% in Poland, the differences between age groups and genders are only marginal.