By Ron Lynch, president/owner, R J Lynch & Associates

After almost 50 years involved with web-handling and consulting, I have seen a few mistakes. I must confess, for the first 15 years, I was an untrained hack and made many of them myself. Here are some of the mistakes I have seen and made as they relate to bowed axis rollers, idler rolls and driven rollers, along with some suggested solutions.

Editor’s Note: This technical article won the Web-Handling Committee Best Paper Award at the AIMCAL R2R USA Virtual Conference held online in October 2020. Part 1 of this article covered dancers & accumulators, and web guides. Part 3 – in our 2021 Q4 issue – will discuss cambered webs, roller surfaces and troubleshooting.

Bowed axis rollers

Bowed axis rollers frequently are used to remove wrinkles: They are effective at removing wrinkles, and they provide an infinite number of ways to make mistakes. There are other uses than wrinkle removal, and each has its own specific setup to do the intended job, but here I will just talk about wrinkle removal.

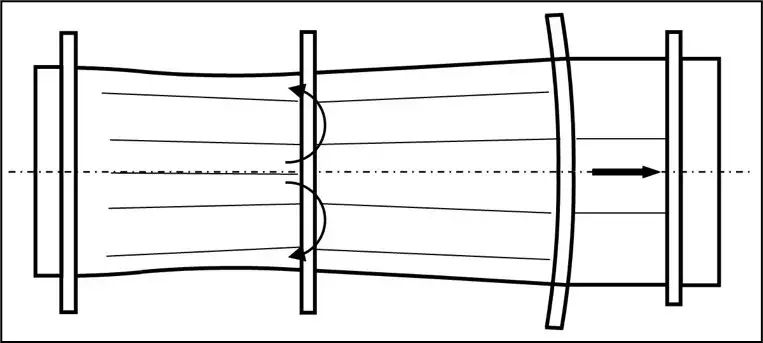

Incorrect bow orientation is a common problem (see Figure 1). For wrinkle removal, the recommended setup is to have the perpendicular to the direction of the bow bisecting the wrap angle. Said another way, if the wrap angle is 60°, the direction of the bow should be rotated about 30° away from the plane of the incoming web toward the plane of the outgoing web, i.e., half of the wrap angle. This provides nearly equal paths over the bow for every lane of web so each lane across the width of the web is stretched the same as the other lanes. This avoids overstretching part of the web and creating baggy centers or loose edges in the web. If the bow is pointed straight into the web (see Figure 1), the center of the web is stretched more than the edges, and there is no spreading, unless the web is sliding, in which case, it works like a very expensive bow bar or D-bar. Pointing away from the web may cause wrinkles, and pointing upstream will cause wrinkles.

You can’t have too much money, but you can have too much bow! Not much bow is needed to remove wrinkles. Too much bow can give erratic spreading due to slipping and can cause wear on the roller near the edges of the web. Manufacturers will have recommendations on how much bow is right for all the various applications.

Bowed axis rollers are intended to be in full traction. If they are undriven, they need enough tension, wrap angle and coefficient of friction (COF) with the web to maintain traction and drive the roller at web speed. Undriven bowed axis rollers are not good idlers, so they need webs that can tolerate and run at higher tension to be able to drive them. For low-tension webs, they generally need to be driven. If the cover wears quickly or looks polished, the web is probably slipping.

If the bowed roller must be driven, it needs to be driven at the correct speed. For most webs and situations, this means driving it within a few fractions of a percent of the speed of the next driven roller. The problem is the curvature of the shaft makes the drive pulley not square to the rest of the line, and variable depending on the direction and amount of bow. V-belts or round belts frequently are used to allow for the angular misalignment; however, neither of these is good for accurate speed control. Speed errors can cause tension problems or allow slipping – neither of which is good for the roller or web. Dedicated and coupled motors can be used to drive the bowed roller at the correct speed but, however they are driven, bowed-roller speed must be monitored regularly and maintained like any other driven roller.

The approaching span length to a bowed roller can be too short. Most of the spreading happens in the approaching span, not on the roller. A short span limits the spreading potential of the roller, or worse, causes wrinkles in the approaching span. I have seen wrinkles first appear in a far too short span approaching a bowed roller and then propagate downstream from there. If you add a bowed roller in a desperate attempt to solve a wrinkle problem on an existing line, achieving the correct span length is more important than settling on a convenient mounting location.

Bowed axis rollers can have the same moment transfer problem that steering guides have (see Figure 2). If you are slipping on the roller upstream of the bowed axis roller, moment transfer will make the edges of the web in that span track closer to each other. This can cause wrinkles to form in the span approaching the slipping roller. I once saw slit webs, which tracked parallel to each other everywhere else, overlap as they approached the slipping upstream roller. It was moment transfer at work. A few spans downstream, they became interwoven parent rolls, the very problem the bowed roller was meant to prevent. Not only must the bowed axis roller be in traction, but the next upstream roller also must be in full traction.

When not set up correctly, bowed axis rollers and web guides are examples of correction devices that can cause or magnify the problem they were installed to correct. Read and understand how these things work and follow the rules.

Idler rolls

The ideal web path, from the web’s point of view, is all driven rollers and no idlers. Idlers have two uses: They are the low-cost way to make up and down changes in the web’s direction, and they are sometimes used as a low-cost backup roller in a process.

Idlers eat the web’s tension. The more idlers you have, the higher the tension you must set to feed them. Fewer idlers are better if you want to run lower tension. Review every web path before it is built to see if you can eliminate idlers. It saves money, and it minimizes idler-related problems.

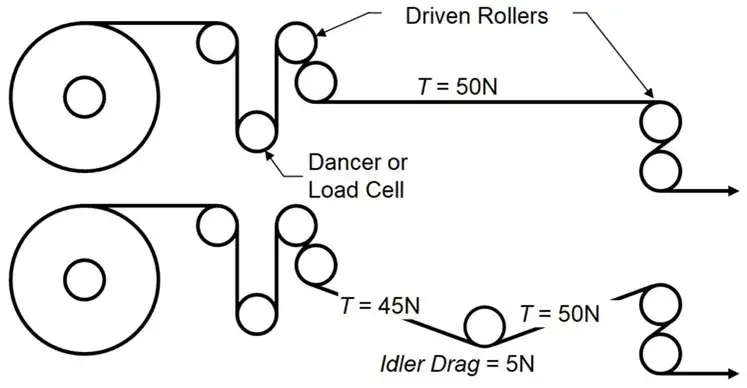

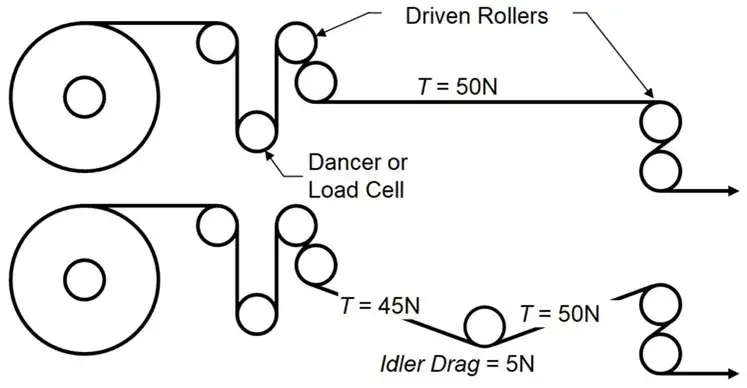

Idlers don’t increase tension; people increase tension. More than once, I’ve heard someone say that idlers increase the tension or an idler was added to a path to increase the tension. This is a fallacy. I think the idea comes from pulling a wagon. If you put more stuff in the wagon, you have to pull harder. But that is not the way webs work. Driven rollers and brakes create tension. Idlers eat tension, and the tension upstream of an idler is lower than the downstream tension that is pulling it (see Figure 3). The only way tension can increase after adding idlers is if someone or a load cell adjusts a driven roller or brake to compensate for the tension lost to the new idlers. If you need more tension, just turn it up. Don’t add rollers you don’t need.

Don’t run tension outside your idler’s design range. Size does matter. Idlers, and all other types of rollers, generally sized to run in a tension range based on the web for which they were originally designed. If you try to run a web and tension outside of the idler’s design range, your idlers can be too heavy or too small for the tension you are trying to run. Too large and heavy an idler, or too many idlers, in an accumulator or along the web path can wreak havoc with tension during starts, stops and splices. Too small of an idler in an accumulator or along the web path can have deflection problems and be a wrinkle-generator. Know your idler’s design range and design your processes to stay within that range.

Driven rollers

Slipping on driven rollers is the ultimate failure. The roller may be going at the correct speed, but if the web is slipping on the roller, the web is not at the correct speed. When the web is slipping on a driven roller, velocity control is lost and along with it goes tension, registration and phase control. The tension ratio, wrap angle and COF must be such that the web does not slip on a driven roller during any expected operating condition.

Don’t underestimate the importance of having driven rollers in the right place and at the right speed. Their job is to control the velocity of the web and, therefore, its strain and tension. If the speeds of driven rollers aren’t set to appropriate targets, don’t accurately follow their ramps, don’t quickly settle to their target’s speeds or oscillate about their targets, there will be tension upsets. On startups, this can delay the production of good product. During splices, it can cause failures. During steady state, it can cause variation in the product, and on shutdowns, it can leave you with a poorly tensioned web that can lead to more transients on the following startup.

You can estimate the cost of a driven roller and may be temped to reduce project costs by skimping on the number of driven rollers in a web path. The problem comes from not being able to see the cost of reduced adjustment capability, intolerance to normal variation and limited material-grade options in the future.

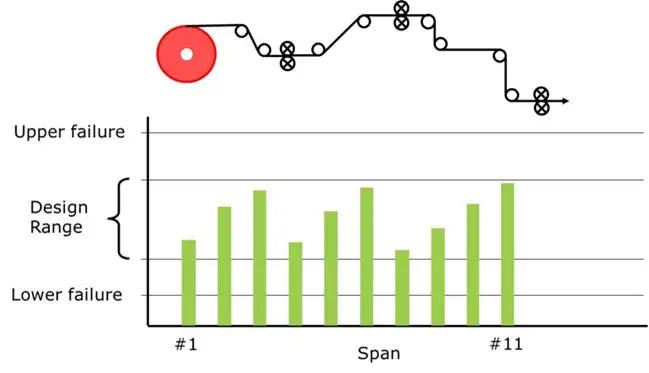

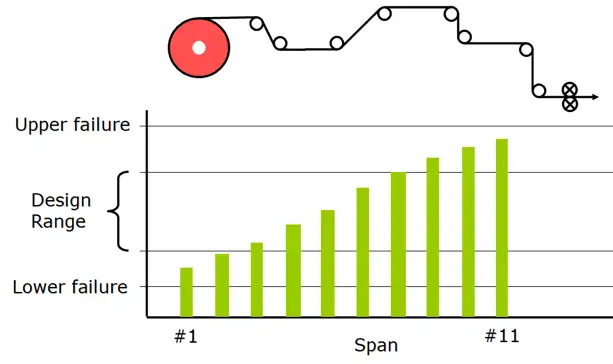

So, how many driven rollers are needed and where do you put them? In a well-designed web path, driven rollers are distributed along the path to balance idler drag and keep tension within the intended operating range (see Figure 4). Too many drives waste money, too few forces you to run tensions closer to the web’s failure limits. You are left with no room for adjustment and can’t tolerate normal variation of the web and process (see Figure 5). In a future article, I will talk about web path modeling and how to locate driven rollers within a web path.

Conclusion

As a web-handling trainer and consultant, my goal is to have people not make these mistakes. There is no substitute for having trained, willing and empowered employees to avoid and solve web-handling problems. Anything less is a mistake.

Ron Lynch, president/owner of R J Lynch & Associates, holds a Bachelor of Science in Mechanical Engineering from the University of Cincinnati and is a registered Professional Engineer. He worked 39 years for Procter and Gamble, with 36 of those years working with web products and web-handling. In the early 1990s, Ron became the in-house web-handling trainer and consultant for P&G’s web-based products and their equipment and web suppliers. He has conducted more than 200 classes and trained over 3,000 engineers and technicians on web-handling in 10 countries on four continents. He was the principal instructor for the Basic Web Handling Seminar at the Web Handling Research Center at Oklahoma State University from 2000-2019. Today, R J Lynch & Associates provides web-handling training and consulting services for clients. Ron can be reached at 513-503-5160, email: ronjlynch@hotmail.com.