By Daniyel Firestone, president, Norstone, Inc.

Editor’s Note: The following paper won the 2019 John Matteucci Award for Technical Excellence for Web Coating at the AIMCAL R2R Conference USA 2019 in Myrtle Beach, SC.

Abstract

Most manufacturing processes require mixing and/or dispersing of liquid products at some time in the manufacturing process. The operation of mixing and/or dispersing can be a critical step, at times determining if the final product is a success or failure. Most operators using blades to mix and disperse have not been informed about how to choose the optimum blade, how to set up the tank for optimum performance or how to best operate the blade for maximum results. This paper will review the differences between mixing and dispersing, general rules for optimum mixing, general rules for optimum dispersing, blade styles for mixing and blade styles for dispersing.

Dispersing

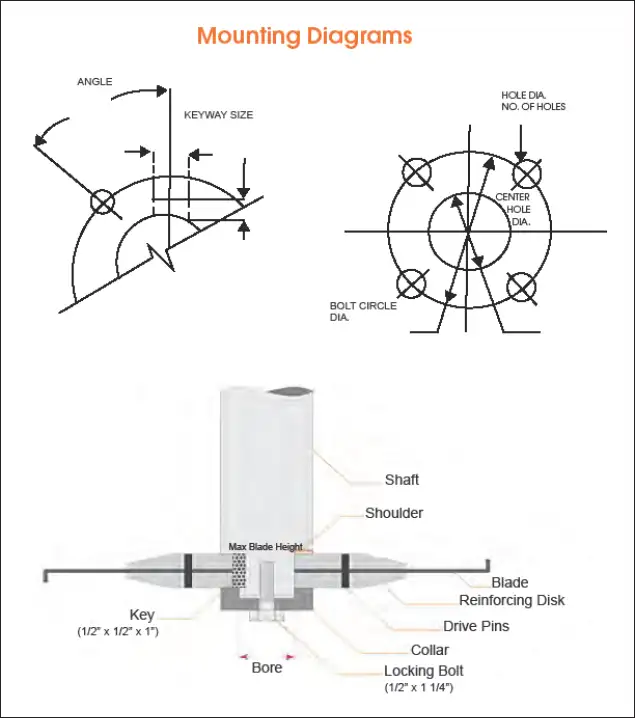

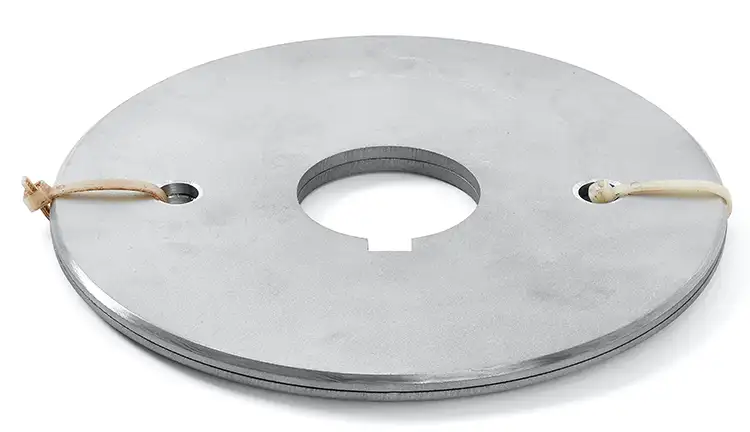

Generally speaking, a dispersing blade is a blade that fits onto a disperser that is built to run at high speeds, forming a vortex and creating shear on the surface of the blade. The blades are flat and bolt onto the shaft using a center bore with pins/bolts or a center bore with a keyway sandwiched between stiffening plates. They can be found with welded collars and set screws being placed on mixers rather than dispersers, but this can be very dangerous. They can be found with center bores and no pins or keyway, but there is nothing to prevent the blade from spinning unless there is a strong compression-plate type fitting.

Most dispersing blades are designed to run at a 4,000- to 6,000-fpm tip speed, which is calculated based on the blade geometry of 1/3 diameter of the tank and 1 hp/10 gals with the diameter of the tank being equal to the height of the liquid.

There are a number of different types of dispersing blade styles. Various styles have different optimum tip speeds. It is important to understand the blade type being used and whether the goal is to disperse or mix on a disperser.

To calculate tip speed: Take the Blade Diameter divided by 12; multiply by 3.14; multiply by shaft RPM.

- Steel tooth-style dispersing blades – 5,000-5,500 fpm

- Steel tooth-style dispersing with pumping – 4,000-4,500 fpm

- Steel tooth-style with low-shear pumping – 4,000-4,500 fpm

- Polyblades without teeth – 4,000-4,500 fpm

- Polyblades with teeth – 4,500-5,500 fpm

- Ring blade – 5,800-6,000 fpm

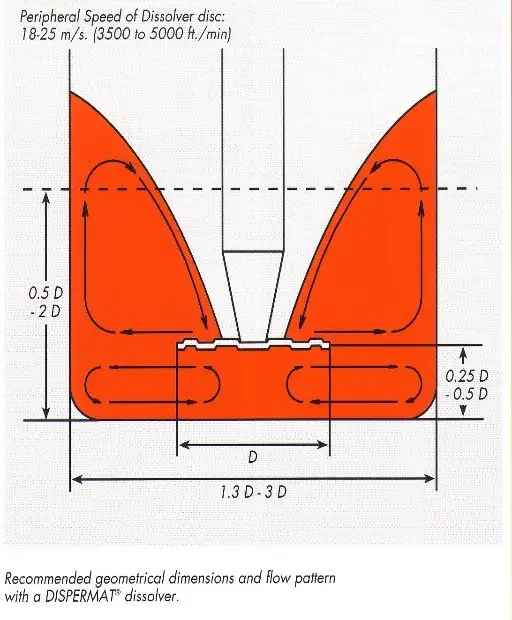

The ideal setup of the tank for dispersing should be such that the liquid level of the tank should equal the diameter of the tank with a dished bottom (see Figure 1). While the ideal, most plants must work with the tanks that they have. A specific blade design could be chosen to help optimize the dispersing process in a less-than-ideal tank.

In addition to blade speed, blade size also is critical with relation to tank diameter. Each style has an optimum diameter-to-tank ratio:

- Steel blades, low to medium viscosity – 33% tank diameter

- Steel blades, medium to high viscosity – 50% tank diameter

- Polyblades, low viscosity – 25% tank diameter

- Polyblades, medium viscosity – 28% tank diameter

- Polyblades, high viscosity – 33-50% tank diameter

- Ring blade – 25-40% tank diameter

Each style has an optimum height position in the tank:

- Steel blades – ½ blade dia. off tank floor

- Steel pumping blades – 2/3-1 blade dia. off the tank floor

- Polyblades – 2/3-1 blade dia. off the tank floor

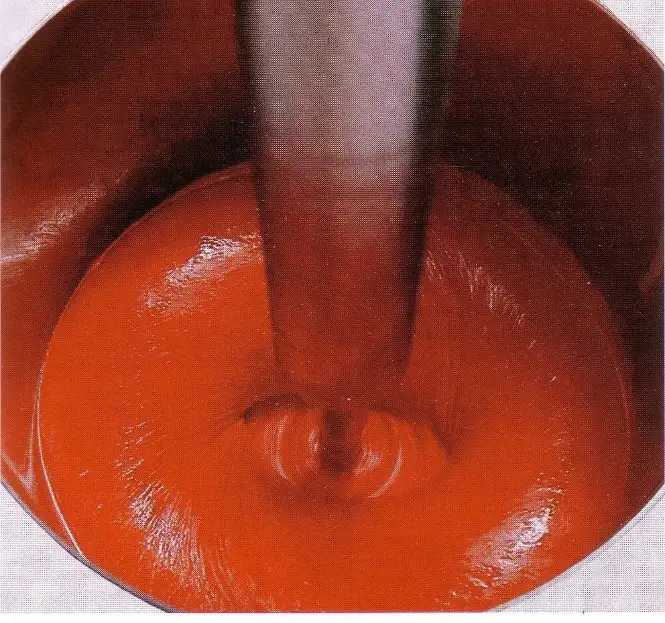

During operation, the blade should never be exposed more than where it meets the shaft during the rolling donut-type of vortex (see Figure 2). Keep in mind the following: 1) Dispersers require approximately 1 hp/10 gals for viscosities up to 2,000 cps. The higher the viscosity, the more power is required; this can be either in terms of speed or torque. The higher the speed, the lower the torque and vice versa; 2) They should be centered in the tank or just slightly offset; 3) Baffles cause an interference and should not be used with dispersers.

Disperser shafts should be centered in the tank or just slightly offset. Swirling is not an issue with dispersing blades. Disperser blades use a vortex to feed the shear zone of the blade. Baffles cause an interference and should not be used with dispersers. For dual-shaft dispersers that have a center-mounted scraper blade, the disperser blade is forced to be placed on the side. This handicaps the dispersing process both due to the placement of material to the side but also due to the reduced size of the blade needed to fit into that space. The scraper blade helps by feeding the material to the blade, but in this situation, it is that much more critical to choose the correct style of blade; i.e., a blade that can both disperse and pump efficiently.

Critical accessories for dispersers would be:

- Stiffening plates are needed for steel blades to control a fluttering effect during high shaft speeds to delay fatigue.

- Stiffening plates are needed for plastic blades to prevent the holes and keyway from stretching (see Figures 3-4).

- Blade guards are very important for steel blades (see Figure 5). In many applications, especially abrasive ones, the teeth and other edges on the steel blades can get razor-sharp. Guards are important to prevent personnel from getting cut during times when the machine is idle and the blade is exposed to operators and maintenance personnel. One of the many benefits of polyblades is that they do not sharpen with wear and thus remove a safety hazard from the plant.

Saw-tooth blades: The saw-tooth style blade is the most commonly used high-shear blade (see Figure 6). It is an excellent shearing blade and can keep air entrainment to a minimum. However, it does not do a good job of pumping and can get very sharp with use. The blade and teeth can bend if a heavy product is dropped on it or it hits the tank sidewall, and bent teeth will not perform as well as aligned teeth. This style blade can be made in various thickness gauges and also be hard-coated for longer life. Price-wise, it is the least expensive style and consequently is the most popular but not necessarily the optimum for the process.

Steel blades: For processes requiring steel blades, there now are many different styles to consider. There are blades that can shear and cut, blades that can shear and pump, blades that are low-shear that pump and blades that can aerate.

Polyblades: A new and growing group of dispersing blades is the polyblade, which has numerous benefits (see Figures 7-8). These were originally designed for abrasive products and products sensitive to metal contamination. Customers who prefer polyblades state that the No. 1 reason is safety because the blades do not sharpen with use. Additional benefits are as follows:

- High shear with excellent pumping

- Dual-sided and can be turned over when the initial side wears

- Last far longer than steel blades, sometimes 2 to 20 times

- Teeth can’t bend nor can the blade itself

- There are many designs, some that run cooler than steel blades

- Available in many polymers depending on solvent and temperature requirements

- Can run at slower speeds and still be quite effective

- Available on a free trial basis up to 16 in. in diameter

- Available in a one-sided design for reduced air entrainment

Mixing

Mixing is a much simpler process than dispersing with fewer variables. A mixing blade is a blade that fits onto a mixer with a collar and set screw. It is built to run at low to moderate speeds, creating an axial and/or radial flow to provide good blending of different products, prevent product from settling, transferring temperature from a tank jacket or keeping products in solution. Mixing blades do not require stiffening plates, and they cannot fit onto dispersers. Unlike dispersing blades, they work well in tall tanks and can be stacked onto the shaft to ensure efficient mixing from top to bottom.

Mixing blades are designed to run at approximately 1 hp/100 gals. Depending on viscosity, the blade can be 25% to 50% of the tank diameter and made to pump up or pump down.

There are a number of different types of mixing-blade styles. Various styles create different flow patterns, so it is important to understand the possible patterns to choose the proper blade. They also operate at different speeds and viscosities.

Shaft location for mixers can be placed in the center or off-center. When centered, there is the potential for swirling where the material runs around the outside of the tank, and thus does not mix the product. This can be prevented with the addition of baffles.

Daniyel Firestone, president and owner of Norstone, Inc. (Bridgeport, PA) since 2000, holds a Bachelor of Science from Temple University and an MBA from Humboldt State University. She has 27 years of experience working with particle-size reduction, grinding, dispersion and mixing equipment and media. Norstone is the inventor of the polyblade with teeth and radius scoops. She enjoys consulting with customers on the topics of blades, media, milling, mixing and how to improve the manufacturing process. She can be reached at 267-246-3416, email: daniyel@norstoneinc.com, www.norstoneinc.com.