By Emily Williams, innovation and sustainability partnerships leader, TC Transcontinental Packaging

This article presents a top-down review of sustainable-solution development for flexible packaging, starting with consumers and legislation creating new demands for sustainable packaging, how that influences retailer and CPG requests, and what that means for TC Transcontinental Packaging as a converter and our supply-chain partners.

Editor’s Note: This paper is based on the author’s presentation at the ARC R2R USA Conference held in Milwaukee, WI, in October 2023.

Developing meaningful sustainable-packaging solutions can be a daunting challenge. How does one know what is “real?” Are you solving one problem while creating another? What are brand owners, retailers, or consumers really looking for? To understand the challenges and how they should influence choices in package design, you must start at the top of the supply chain. The relationships between consumers, NGOs, regulators, retailers and brand owners must be understood. Beginning with this view, looking at the legislative landscape that impacts these parties, it becomes easier to understand the choices converters are making and how supply-chain partners can help move these innovations forward.

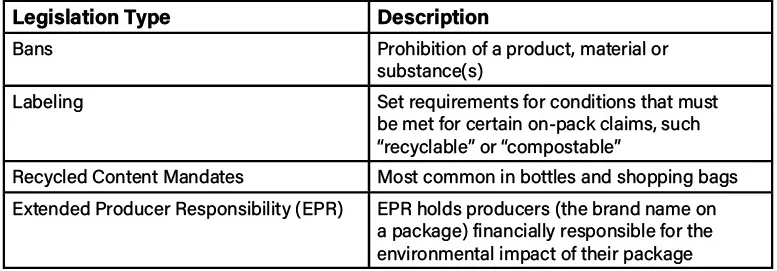

In a perfect world, sustainable packaging would be a core value, with buy-in from the operators to the executive suite. The work should be done because it is the right thing to do, and brand owners would choose the more sustainable-package option accordingly. We all know that this idealistic view is not reality. As a result, governments are increasingly turning to regulation to force packaging innovation to move in this direction. At TC Transcontinental Packaging, we follow four key categories of legislation (see Table 1).

Basics of EPR and eco-modulation

Of these, extended producer responsibility (EPR) is a key focus for many brand owners and retailers, as they are the designated producers in an EPR scheme. The producers generally are the responsible party in an EPR scheme for both developing a plan that meets a law’s requirements and for the fees paid into the system. Generally speaking, the goal of these laws is to generate the funds needed to support collection, sortation and recycling infrastructure improvements, by attaching a fee to every piece of packaging sold within a state based on its material, format and weight.

Many of these laws also aim to drive sustainable-packaging design through a feature called “eco-modulation.” The concept behind eco-modulation is if a company makes a package more sustainable: i.e., recyclable, compostable, downgauged, incorporating recycled content, lessens the environmental impact, the fee will decrease (and alternatively, if it makes the package worse for the environment, the fee will go up). There are very limited exemptions to EPR fee programs, most consumer packaging will be subjected to fees. The result is a shift in how companies must view sustainable packaging – from a trendy item that looks good in a marketing piece to a legal imperative with real financial implications.

Now it’s the converter’s turn

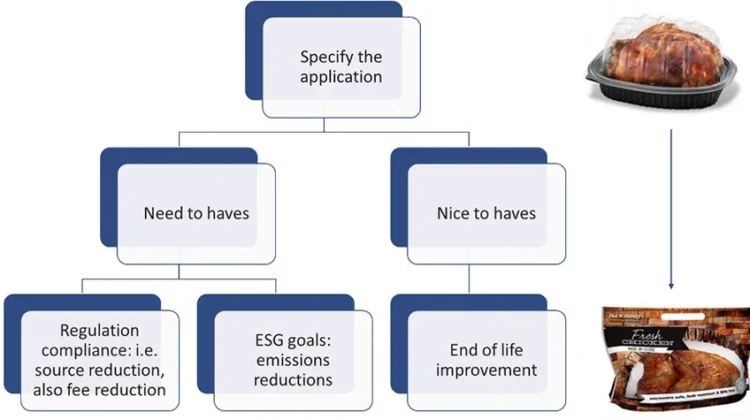

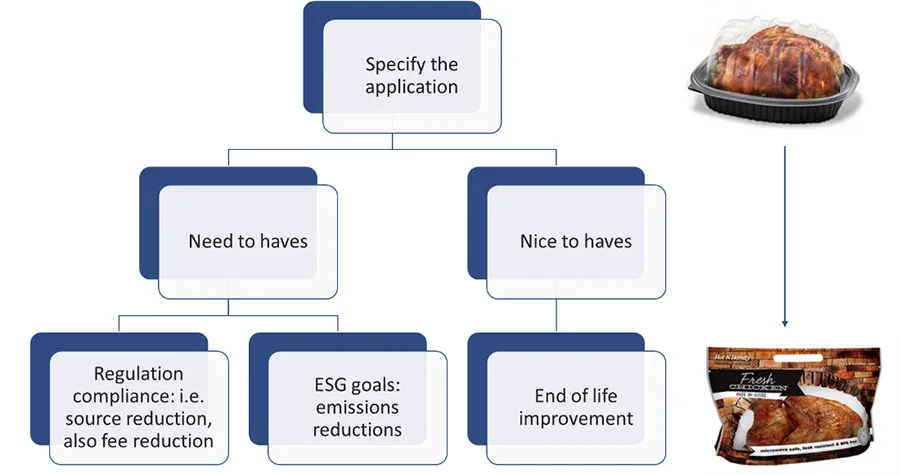

This legislative landscape, in turn, puts pressure on converters to provide solutions. At TC Transcontinental Packaging, we have developed the approach of helping our customers determine the “right tool for the right job.” It is important to recognize that there is no singular sustainable-packaging solution that solves all one’s problems. Solutions must be tailored to the goals of a company and to the needs of a particular application because, at the end of the day, the most important thing a package must do is protect and preserve its contents.

Accordingly, we always start these conversations by identifying an application of choice. The example we will use here is the faithful rotisserie chicken sold at grocery stores across the country. These chickens are sold in huge quantities; one retailer alone may sell more than 100 million a year. Historically they have been sold in rigid containers comprised of two pieces: a tray and a dome. With the application determined, the discussion can begin (see Figure 1).

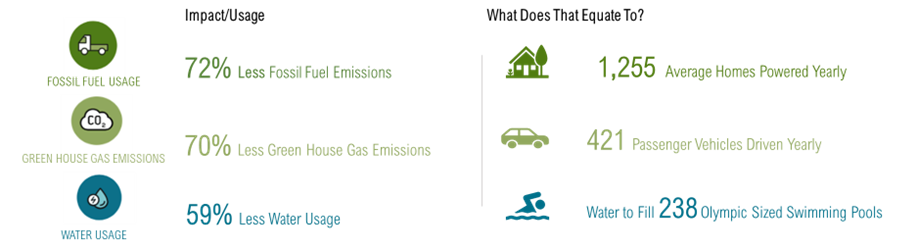

Through this discussion, a solution is determined, which is a flexible pouch. This pouch has a zipper, can stand up to the heat of the retailer’s hot case, is easy to carry, requires significantly fewer boxes and back-of-house space, and fewer trucks to ship the pouches. These are all appealing attributes and could lead to a very attractive on-pack claim. Anytime a claim or label is being discussed, it is important that the verbiage used is backed by supportive evidence. At TC Transcontinental Packaging, we have several sources for data, depending on the application of choice. This includes validation of recyclability per APR guidelines to obtain How2Recycle labels, compostability certification, procuring certified recycled materials, and uses life cycle analyses (LCAs) to look at overall environmental impact.

In the case of the chicken package, emissions were at top of mind in initial discussions. An LCA was performed to determine the environmental impact of this new package format. Figure 2 shows the data for replacing 10 million rigid containers with the flexible-pouch alternative.

Investing in supporting claims

Providing data to support claims can be time-consuming and expensive, especially when using external labs as required by any certification body. At TC Transcontinental Packaging, we have invested significant capital into expanding our own in-house testing capabilities to ensure success for our customers when moving to an external laboratory. This includes investing in analytical testing equipment, applications and packaging pilot-scale equipment such as a blown-film line; a BPI-recognized, ISO-accredited compost lab; and a recycling lab modeled after the testing performed by PFE to APR guidelines. These facilities save time and money during the development process. Finally, we have invested $60 million into a BOPE-extrusion line and associated building expansion currently being installed in our Spartanburg, SC, facility. This line fills a regional need for material supply in North America and provides what we believe to be superior material necessary for the transition to mono-material flexible packaging.

Partner collaboration is key

Another critical component in the development of sustainable packaging is collaboration with supply-chain partners. All materials and equipment used must be taken into consideration. Raw materials such as inks, resins, coatings and additives all can have an impact on successful development. Are they free of any bad-actor chemicals that may be found in a toxicity ban? Can they aid in achieving specific sustainability goals such as recyclability, compostability, downgauging, waste and residue reduction, deinking or decreasing emissions? If they can, is there data to back it up?

There is an astounding amount of fascinating innovation happening around the globe; the challenge for a converter is establishing what provides a tangible change in a development, and this requires data. Supply-chain partners that come prepared with data or a clear plan on how to obtain the necessary data find themselves moved to the front of the line for collaboration. Another key requirement for many, including TC Transcontinental Packaging, is FDA food-contact approval. Due to the sensitive nature of direct food-contact packaging production within our facilities, we cannot bring in materials that do not meet these standards.

Equipment manufacturers also play a key role in supporting sustainable-packaging development. Materials used in sustainable alternatives are both chemically and physically different from what has traditionally been used. This presents a production and converting challenge as there is significant existing capital in equipment designed to run the incumbent packaging materials. Moving to mono-material polyethylene packaging in a flexible pouch from a multi-material laminate presents many such challenges due to the different properties of the polymers used. Can this equipment be modernized to allow new materials to be run at equivalent efficiencies? Additionally, can it be modified to improve efficiency and reduce emissions? This aids corporations when reporting out their ESG goals.

Conclusion

Ultimately, what a converter needs from supply-chain partners is active participation and alignment of innovation efforts to support brand-owner and retailer goals. This can be achieved by maintaining awareness of the legislative landscape and understanding how it influences decision-making at converters and their customers and participating in the right industry organizations. If you have questions no one in your organization can answer, then there is an organization you can join that can. Key groups that TC Transcontinental Packaging uses include AMERIPEN, the Assn. of Plastic Recyclers, the Biodegradable Products Institute, ASTM and the Sustainable Packaging Coalition.

Sustainability can no longer be viewed as a trend; rather, it must be viewed as a requirement. If the topics discussed here are new to you, then you already are behind, and it is time to get urgently involved.

Emily Williams, innovation and sustainability partnerships leader at TC Transcontinental Packaging, holds a Bachelor of Science in Chemical Engineering from The Ohio State University and a Master of Science in Chemical Engineering from the University of Cincinnati. TC Transcontinental. Packaging is a leading flex-pack converter with operations mainly in the US, as well as in Canada, Latin America and the UK, serving a variety of end markets. Prior to joining TC Transcontinental Packaging, Emily held product development and product management roles for a coatings supplier where she worked with water-based coatings for film and paper packaging for recyclable, repulpable, and compostable applications. She has been a panelist and speaker at numerous industry conferences and is involved in several industry groups including the Sustainable Packaging Coalition and AMERIPEN. Emily can be reached at 513-276-6632, email: emily.williams@tc.tc, https://tctranscontinental.com/en-us/packaging.