By Emily Williams, global growth platform leader-Circular Economy, Michelman

Editor’s Note: This technical paper is based on a presentation at Specialty Papers US 2019, held in Milwaukee, WI, and organized by Smithers.

Abstract

As we look to innovate a more sustainable future for our planet through development of packaging that fulfills the vision of a Circular Economy, existing paper-based foodservice packaging (FSP) has inherent end-of-life challenges, resulting in a focus on developing compostable packaging. Creating fiber-based solutions for compostable foodservice packaging faces an unusual set of requirements which are governed by regional standards, certification bodies and infrastructure challenges. This article is an in-depth examination of how to develop verified solutions for compostable packaging that will help achieve goals consistent with the Circular Economy model.

Introduction

It is essential to understand the purpose of compostable, paper-based foodservice packaging (FSP) before hypothesizing and designing solutions. Most food waste today ends up in landfills, and consumers erroneously conclude that it biodegrades on its own. If compostable packaging is developed and employed, the result will be more food waste that is diverted from landfills.

Food waste is a valuable feedstock in compost piles. Diverting food waste to industrial compost facilities together with foodservice-packaging products requires that the packaging component be verified as compostable. Therefore, foodservice articles present a tremendous but challenging opportunity for innovation. Many types of potential solutions are available for fiber-based foodservice articles, but each has its challenges regarding compostability. Acceptable solutions for compostable packaging must meet a multitude of criteria, which vary regionally. The goal of this overview is to allow the reader to learn more about what “compostable” means, how to meet differing global standards on compostability, market drivers and availability of infrastructure for composting.

Current paper-based FSP uses a variety of barrier solutions to meet functional requirements. These range from extruded materials, such as polyethylene (PE) or polylactic acid (PLA) resins, to treatments applied on the paper machine at the size press, such as starches and perfluorinated alkyl substances (PFAS), or coated applications, such as waxes or water-based coatings. All are valid solutions that meet real needs with a range of end-of-life options, depending on the extent of their food contamination. For example, size-press treatments and water-based coatings enable the recyclability of a minimally contaminated fiber-based article. Extruded PLA is industrially compostable, and PFAS, previously permitted in industrially compostable articles, will be discussed in further detail later in this analysis.

Biodegradation and industrial composting

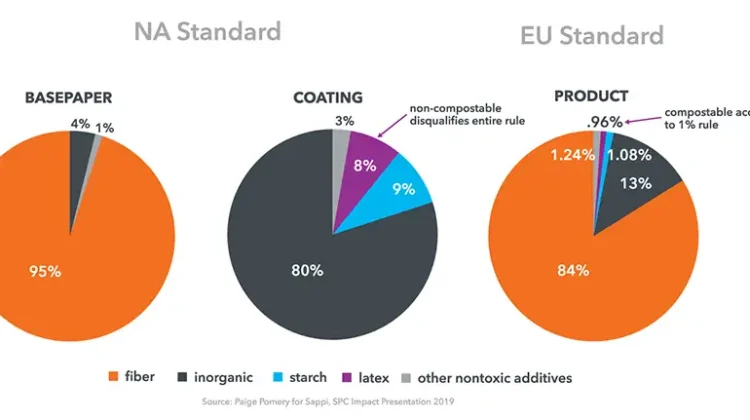

Global standards exist for material certification for industrial composting and include a range of conditions under which biodegradation occurs. There are common misconceptions over the terms “biodegradable” and “compostable.” Biodegradability does not mean that a material is compostable as biodegradation occurs in a variety of environments, some of which are highly controlled and aggressive, and others which are not (see Figure 1).

Industrial-composting environments have very aggressive biodegradation. Highly controlled by moisture, oxygen and temperature, they allow the appropriate fungi, bacteria and actinomycetes to thrive and degrade materials effectively. Comparing industrial composting to landfill, biodegradation is less aggressive and controlled in a landfill. Material breakdown will take a longer period of time in a landfill than in an industrial composting facility. For example, a head of lettuce in an industrial composting environment may degrade within a few weeks. In a landfill, that same head of lettuce may take up to 25 years to degrade.

There are testing standards for all of the biodegradation conditions listed in Figure 1 if one chooses to target that environmental situation for end-of-life as it relates to fiber-based FSP development. These standards are available through bodies such as the International Organization for Standardization (ISO), American Society for Testing and Materials (ASTM) and Organization for Economic Cooperation and Development (OECD). Conspicuously absent from Figure 1 is what one might refer to as “roadside” or simply litter for end-of-life design. Why is this? Because it is impossible to standardize a field test around this scenario – such as how long an item might take to biodegrade on the side of the road. The environmental influences and environment on the side of the road in the United States is different from that of France, China, India, etc. Therefore, no standards exist for typical roadside litter.

What exactly is biodegradation, what does it mean in an industrial-composting environment and what testing is required? As previously mentioned, an article can be biodegradable but might not necessarily be industrially compostable. Biodegradation is one of several tests a material must pass for validation for industrial compostability. These core tests include the following:

- Specified limits for heavy metals and fluorine content

- Biodegradation

- Disintegration

- Eco-toxicity

Biodegradation and disintegration are two different tests. Biodegradation is the actual conversion of ≥90% of the organic carbon present in a material to carbon dioxide, water and biomass within 180 days in controlled test conditions. Disintegration is the physical breakdown and visual disappearance of the material. No more than 10% of the original material can remain on a 2.0 mm sieve after 12 weeks of controlled composting. Eco-toxicity means that the material does not hurt the ability of the compost to support plant growth. Eco-toxicity also is the test that sets usage limits, a critical consideration when developing additives and coatings for paper. A material’s validated usage limit is a dry-weight percentage and becomes the upper limit for use in an application.

The 1% Rule

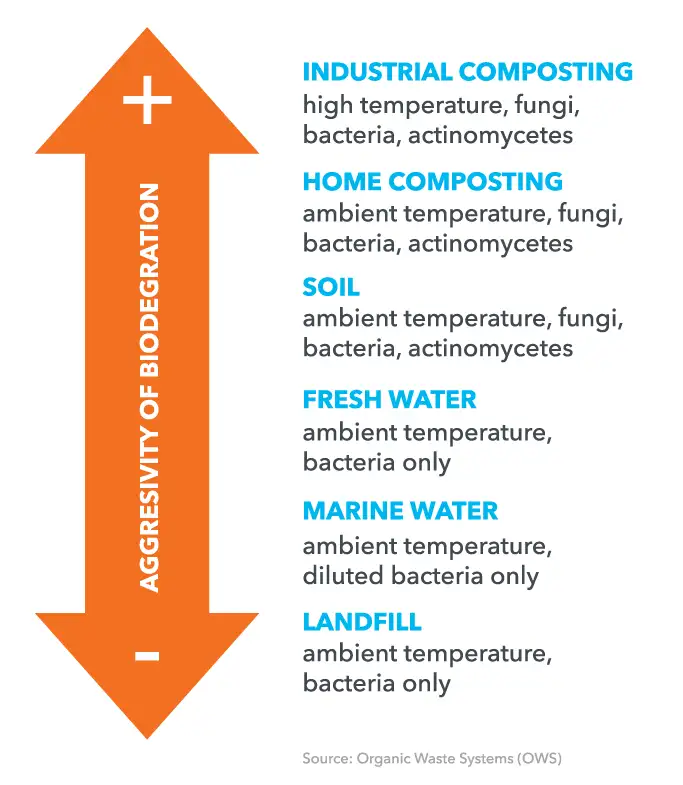

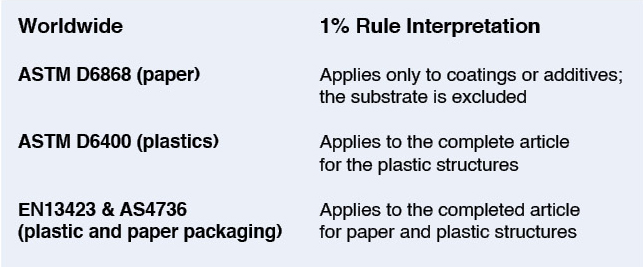

The 1% Rule, described in Table 1, also is critical when determining if a solution is compostable, according to a given standard.

Small material changes that may seem inconsequential, such as changes in preservatives, have an impact on materials that may have been verified already and require new testing. Locking-in formulae and maintaining tight procurement, quality standards and documentation around verified compostable materials are vital in maintaining compliance. Multiple components that are <1% that are not biodegradable are permitted, but the sum of those additives may not be higher than 5% and they cannot be chemically identical. For example, applying 0.99% of the same material three times is not permitted. These rules exist within all global standards and typically are applied to the completed article, with one standard being the exception (see Table 2).

In general, these standards are quite similar but have some minor differences. For instance, the same core tests are required for all, and the 1% Rule is interpreted equivalently in EN13432, ASTM D6400 and AS4736. It is important to note that the ASTM standards for compostability are separate for plastic and paper, and there is not a single standard for packaging. This lack of a single packaging standard is the reason for the discrepancy in interpretations of the 1% Rule.

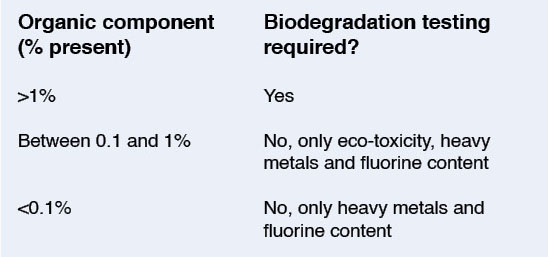

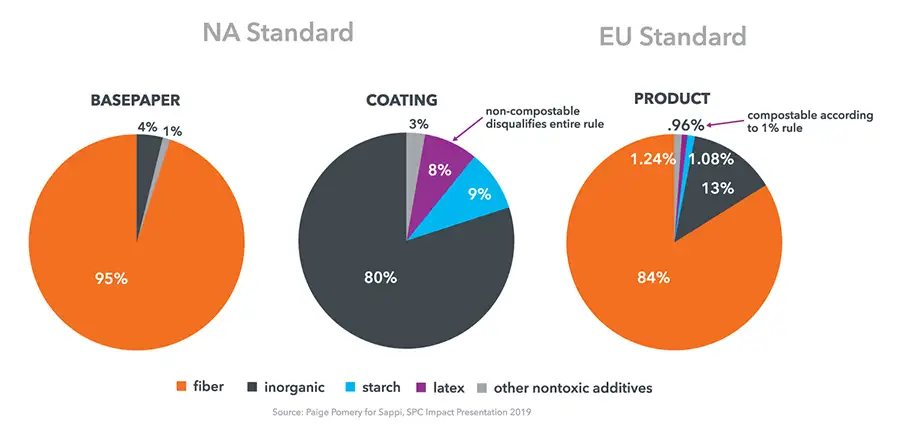

When looking to determine what types of coatings or additives to use, there is a sharp difference between applying the 1% Rule to the coatings or additives vs. applying it to the completed article (see Table 3). When referring to the finished article, there is a coatweight limitation. Any solution, regardless of chemistry, which passes eco-toxicity testing and is within the heavy metals and fluorine content limits, can theoretically be used in a finished article. Figure 2 (Sappi 2019) illustrates the distinction between the United States standard for paper products (ASTM D6868) and other standards. It outlines a 250-gsm finished-paperboard product, of which 220 gsm is the substrate and 30 gsm is a coating.

This difference in interpretation makes meeting the US standard very challenging for paper products, and meeting this standard is a requirement to be certified as compostable in the States. There are four major global certification groups. The Biodegradable Products Institute (BPI), based in the United States, abides by the ASTM standards. TUV Austria, known for OK Compost, based in Europe, abides by EN13432. The Bureau de Normalisation du Quebec (BNQ) follows the ISO standards and supports the 1% Rule interpretation outlined in EN13432 and AS 4736. Finally, the Australian Bioplastics Association (ABA) uses AS 4736.

Importance of regional certification

It is essential to consider the region in which your product will be sold and discarded to determine the appropriate certification body. For example, in the United States, BPI has been working closely with composters, and many only recognize BPI for certification of products they deem acceptable. This consideration is important especially for parts manufactured around the world – for instance, molded pulp products that are produced in Asia but sold, used and disposed of in the United States.

Historically, these parts have used PFAS to obtain their barrier properties. In 2019, BPI released a new certification structure prohibiting the use of intentionally added PFAS in certified compostable parts. Molded pulp manufacturers now seek new solutions but must carefully choose materials to maintain the desired BPI certification by many end-users. Commercially available materials exist that can meet the performance demands of these parts. Still, the majority are not biodegradable on their own, including most standard latexes, polyethylene and other commonly used packaging chemistries. Because these materials are not biodegradable on their own, they cannot be used in a solution that is targeting BPI certification for compostability.

Once a preferred certification is selected, proceed with testing using an accredited third-party laboratory. BPI maintains a list of globally approved laboratories for reference. All certification bodies require the use of third-party laboratories for accreditation on preferred standard(s). These time-consuming and often expensive accreditations are part of the reason why compostable packaging should be thoughtfully developed based on market needs for appropriate applications. It also is important to keep in mind that changes to a formula or approach, after certification has commenced, may mean that the process must be re-initiated.

Consideration of infrastructure

It also is important to note that infrastructure availability is a significant challenge in the practical use of compostable packaging. The US has areas of developed infrastructure for composting, heavily concentrated on the East and West Coasts with a few facilities in the middle of the country. This lack of infrastructure results in single facilities dominating large areas, thus enabling them to charge prohibitively expensive fees for pick up. Because of this, certain states have established legislation around compostable packaging, while others have none. Despite this, US consumer demand for compostables is very high, likely driven by the assumption that a compostable item will biodegrade anywhere. Consumer education continues to be a missing piece of this work that will have an impact on the success of compostable parts.

Compostable packaging is a tool to successfully divert food waste from landfills. And, to reach an ideal future with significantly reduced food waste, compostable packaging has to meet appropriate global standard(s) and be completed in parallel with infrastructure and collection improvements, and consumer education.

Industry drivers and collaboration

The advancement of products that enable the Circular Economy is more than a trend and has gained widespread adoption, becoming a requirement for many entities who work within the packaging supply chain. Consumer-driven demand for compostable foodservice packaging has caused brand owners to re-think and change their requirements for selection, qualification and adoption of foodservice-packaging solutions. These requirements must conform to evolving and often consumer-influenced legislation at the local, state and national levels for both performance and claims.

Collaboration throughout the supply chain is critical for developing compostable materials and packaging. Understanding the nature of these requests and the underlying drivers are vital to creating and commercializing real solutions. In many applications, taking step changes toward the ultimate goal of compostability may be a sound approach and could be beneficial for all. On the other hand, demanding the final ultimate solution and refusing to consider alternative options may result in lengthy and expensive development projects, of which many may not produce winning solutions and may result in longer lead times to meet sustainability goals than the step-change approach. Developing materials in silos without including the consideration and perspectives of the composters themselves also may result in unsuccessful products that they will not accept. Measured, informed and thoughtful changes in materials are what will lead to successful fulfillment of compostable foodservice packaging that will be a key contributor to and enabler for the Circular Economy.

Conclusion

Compostable packaging is the right tool for a specific job. The development of compostable packaging that meets the appropriate global standard(s) must be done in parallel with infrastructure and collection improvements and consumer education so as to reach an ideal future in which food waste is successfully diverted from landfills.

Emily Williams, global growth platform leader-Circular Economy at Michelman (Cincinnati, OH), holds a Bachelor of Science in Chemical Engineering from The Ohio State University and a Master of Science in the same from the University of Cincinnati. She has over 10 years of experience in R&D of polymeric chemistry, crosslinking, additives and nanoparticles for coating technology. Williams’ particular expertise is in compostable coatings and packaging development, focusing on the design of formulated, water-based coatings for packaging solutions using renewable resources. She is an active member of the ASTM committee for compostable plastics, the Food Service Packaging Institute with the Paper Recovery Alliance, and Plastics Recovery Group, and the Sustainable Packaging Coalition. Williams can be reached at 513-794-4192, fax: 513-305-8783, cell: 513-793-2504, email: emilywilliams@michelman.com, http://www.michelman.com/.