By Patrick Meinen, global product line mgr., Nordson Extrusion Dies Industries LLC

Introduction

Beyond today’s widespread use in consumer electronics, lithium-ion (Li-ion) batteries are expected to grow rapidly in automotive and energy-storage applications. These uses pose great challenges because of stringent requirements for efficient and reliable battery performance. At the same time, global competition forces battery manufacturers to achieve ever higher levels of operational economy and productivity.

Key components in these batteries are the separator films that keep the electrodes apart to prevent short circuits. These films are permeable membranes with 40% to 50% void volume to facilitate ion transport. A common method of producing them is the so-called “wet” process, in which a polyolefin – such as high-density polyethylene (HDPE) that has been impregnated with oil or wax – is extruded from a flat polymer die, then subjected to machine- and transverse-direction orientation before the oil is removed with a solvent, thus producing a uniform fibrous network. The extrusion dies are typically 600 to 780 mm wide at outputs from 200 to 550 kg/hr.

Die design is critical to film uniformity

Even though the separator film provides a passive function in the Li-ion battery, the cost of the film is a significant part of the overall cost of battery production. The film plays a critical role in the electrical efficiency, longevity and safety of the battery. For compactness, it must be as thin as possible – typically 30 µm or less – yet strong enough to withstand the winding process of battery construction and to maintain the mechanical and electrical separation between the electrodes. Permeability must be uniform throughout the area of the film. And, dimensional consistency is essential for ensuring an effective interface with other battery components.

Meeting these requirements calls for – among other characteristics – exceedingly precise thickness uniformity. There are two aspects of die design that help make this possible.

Uniform melt distribution: The function of the flow channel, or manifold, inside the die is to distribute the molten polymer that enters the manifold to the final required width as it exits the die. For battery-separator film, it is especially critical that the thickness and physical properties across the width of the film are uniform. This presents a challenge to manifold design, because the tendency of molten polymer is to exhibit variation in pressure drop across the width of the die as the melt travels from the manifold entry to the die exit.

Designing a manifold that overcomes this tendency and yields a uniform pressure drop across the width of the die requires custom engineering. This is because different polymers exhibit different flow behaviors. Die designers use flow calculations based on a polymer’s viscosity, which can be characterized through use of a capillary rheometer.

Fine-tuned gauge profile: Even with a properly designed manifold, some variation in film thickness can occur across the width of the die. An automatic profiling system that adjusts film thickness as variations occur can overcome this problem. In response to signals from a computerized, downstream thickness scanner that detects variations at points along the width of the film, the profiling system adjusts the thickness at those points. This is possible because the upper lip of the die has an array of adjusters, giving rise to the term “flexible upper lip.”

In the profiling system offered by this firm, these adjusters are thermally actuated bolts that expand or contract to adjust the lip gap in areas of the film that are thicker or thinner than the target dimension. While standard versions of this system are air-cooled, use of ambient cooling recently has become an option. In wet-process production of battery-separator film, the oil from the polymer melt may condense on the air-cooling component and subsequently drip onto the film, causing product defects.

Multiple measures to prevent film defects

Defects such as pinholes, gels, carbonized polymer and contaminants could compromise the performance of the battery, leading to mechanical failure, internal shorts and even safety issues. For this reason, separator-film manufacturers employ rigorous process controls and quality monitoring to prevent defects. A properly designed flat-die system can play a valuable role in this effort while at the same time maximizing “uptime” for producing saleable film.

An expertly engineered die system is sufficiently stable, mechanically and thermally, to minimize the residence time of the polymer within the die, improving product consistency and helping to avoid defects such as gels and degraded polymer. A properly designed system also provides faster purging of the die during a product changeover, preventing contamination and reducing the time needed to reach desired tolerances.

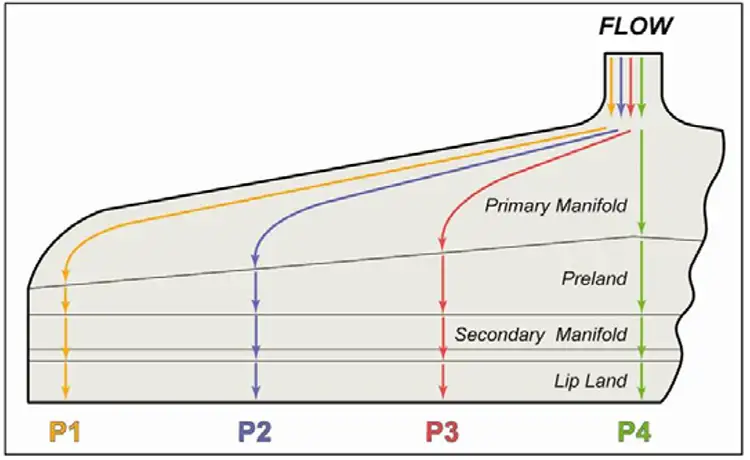

One key to reduced residence time and faster purges is a diminishing-volume manifold, called a “coat-hanger” manifold because of its overall shape (see Figure 1). This manifold has a flow channel whose volume decreases toward each end of the die, resulting in reduced pressure drop and promoting uniform flow across the width of the die (see Figure 2). Besides helping to achieve uniform film thickness, this design provides streamlined, flow-enhancing, uniform film properties across the full width.

The quality of the flow surfaces in the die also affects development of defects. It is recommended that flow surfaces be polished to a mirror finish to provide improved release properties and prevent the mechanical transfer of defects.

Importance of flow-surface plating

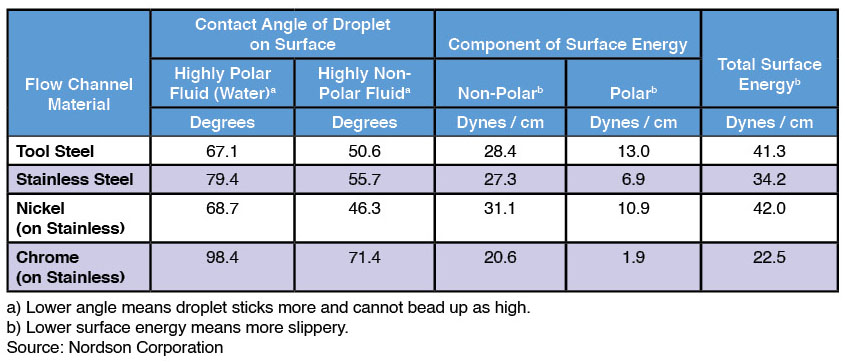

Selection of an appropriate plating for flow surfaces prevents polymer buildup while reducing production downtime. Polymer buildup can contaminate the finished product unless the line is stopped periodically for cleaning. To maximize the run time between die cleanings, a flow-channel surface with low surface energy is needed. Chrome plating has nearly half the surface energy of nickel plating, so surface buildup takes longer to accumulate (see Table 1).

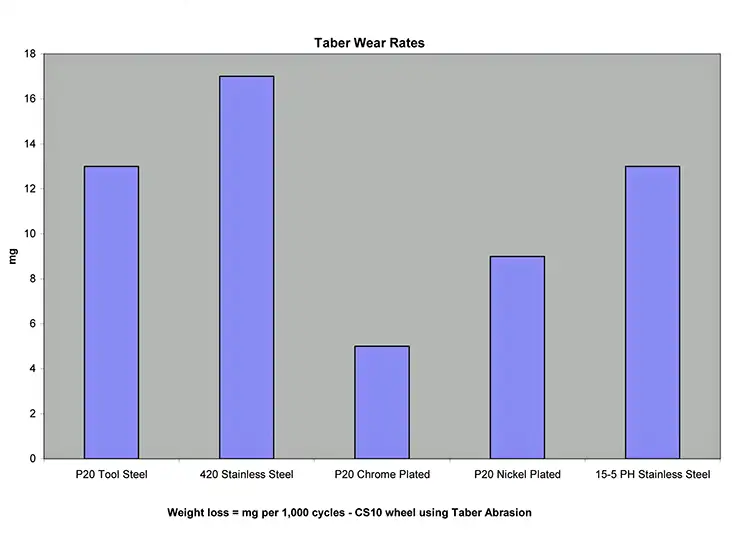

Plating also affects surface lubricity and the length of runs between cleanings. Chrome-plated surfaces are hard, around 65 Rockwell C, and resist wear from cleaning and handling. In a standard Taber Wear Abrasion Wheel test, chrome-plated surfaces wear the least, so surface finish remains highly polished for longer periods for durable, buildup-resistant performance (see Figure 3).

Another defect encountered in film extrusion is that of die lines – striations in the film caused by carbon or other buildup at the die exit. A frequent cause of this buildup is extended contact of the exiting polymer with the lip face. This can be minimized by means of a sharp lip edge, which provides a precise release point for the polymer. It is recommended that the edge have a radius of less than 25.0 µm, be highly polished and uniform, and be made of durable material.

Die-edge coating boosts uptime

One material option offered by this firm for die edges is a coating for the lip lands (the areas just before the exit) and lip faces (see Figure 4). This material reportedly lasts eight times longer than standard chrome plating, enabling the film producer to gain several days of added machine uptime each year. Compared with chrome plating, this coating is substantially more resistant to microfractures during initial sharpening, abrasion during normal use and cleaning, and corrosion.

A lower-cost, lip-edge option is that of laser hardening. The process involves machining away the chrome plating on the lip lands and faces and replacing it with a hardened area that is 0.8 mm deep and has a hardness of 55 Rockwell C. The lip edge can be re-sharpened frequently.

Conclusion

The measures outlined in this article have been employed in numerous battery-production facilities around the world. Die technologies are available for budget-sensitive applications, as well as those that require the most sophisticated and advanced tooling. With demand for lithium-ion batteries likely to be strong for years to come, there is little doubt that die engineers will continue to develop new ways to enhance productivity and quality in separator-film production.

Patrick Meinen, global product line mgr. for Nordson Corporation’s EDI® polymer extrusion dies and feedblocks, holds a degree in Mechanical Design Engineering from Wisconsin Indianhead Technical College (Shell Lake, WI). He joined EDI (which was acquired by Nordson in 2012) as a design engineer in 1996. Subsequently, Meinen served the EDI brand in sales, account management and business development positions. A member of the Society of Plastics Engineers (SPE), he is based at EDI headquarters in Chippewa Falls, WI. Meinen can be reached at 715-726-1201, www.nordson.com/en/divisions/polymer-processing-systems.