By Paul Lembo, exec vp, New Era Converting Machinery, Inc.

Converting-equipment manufacturers face a variety of challenges related to customization when designing and building machinery for the energy-storage industry. The need for customization, whether based on emerging technologies for conventional battery materials, such as electrodes and separators (or other markets, like polymer membranes, impact protection or recycling), drives lead times in an industry which is changing too quickly to work around a typical equipment-manufacturing cycle. The traditional build cycle for custom equipment designed and manufactured in the USA, coupled with recent supply-chain concerns, begs the question, “How can you build standard equipment for a rapidly growing industry that requires custom solutions?”

Introduction

Roll-to-roll (R2R) battery converters face a variety of challenges related to equipment customization for the energy-storage industry. The need for customization, whether based on emerging technologies for conventional battery materials, such as electrodes and separators (or other markets, like polymer membranes and foam cushioning), drives lead times in an industry which is changing too quickly to work around a typical equipment-manufacturing cycle. The traditional build cycle for custom equipment designed and manufactured in the USA, coupled with recent supply-chain concerns, begs the question, “Can there be standard equipment for a rapidly growing industry that, in many cases, requires custom solutions?”

It’s important to understand that standard equipment historically has been a challenge for R2R-converting equipment manufacturers. With R2R battery converters constantly developing new formulations and products while using a multitude of substrates and chemistries, the demands on the equipment change for every project.

Spec’ing a range of specs

There are several factors that affect all sections of an R2R equipment line. For the sake of this discussion, let’s call these the general specifications. In no particular order, these are specifications such as web widths, line speeds and material tension ranges. Any one of these alone can create issues for standardization, but together they challenge all machine builders, as a standard machine would have a predetermined window of operation for all of these. Anything outside this window would affect drive horsepower, roll inertia, gear-in ratio and a wide range of other equipment specs that typically would push converters to custom-designed equipment solutions.

Beyond the general specifications, there are items that relate directly to individual components of the R2R line, which we will refer to as the detail specifications. Detail specs can range from things such as core sizes, roll diameters and roll weights on unwind and rewind equipment to more process-focused items like coating type (solvent, aqueous or 100% solids), laydown rate (thickness), drying rate, percent solids and more. In general, the items related to input and output materials can be accounted for, though some degree of “over-designing” is required and will build in additional cost to the system. However, the process-related detail specifications are quite possibly the biggest hurdle to standardization of everything we will discuss. The coating chemistry alone affects what type of coating method needs to be used; mixing, blending and pumping systems; as well as the type and size of the drying system needed.

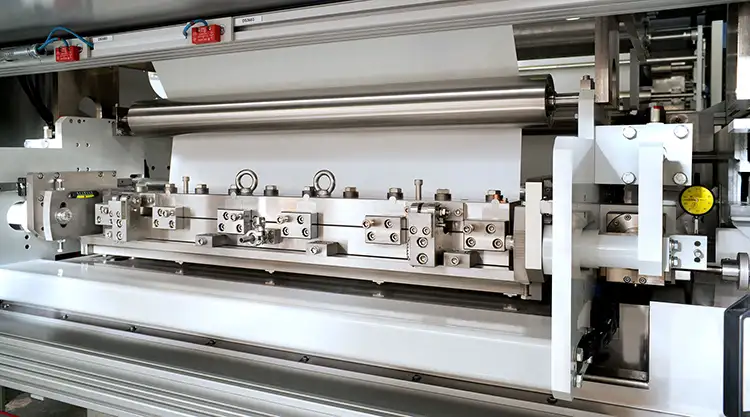

Electrode coating: Breaking these process specifications down by industry makes the picture a little clearer, at least on the electrode coating side (see Figure 1). With a few exceptions, the world of electrode coating for anode and cathode slurries is dominated by slot-die methods (see Figure 2). In addition, the vast majority of the drying is done with long, multi-zone, hot-air systems, though there is a push to move away from solvent coatings and into the UV-curable realm. While this is good news for standardization, machine builders still have to contend with all of the general specs, detail specs and dryer-related process specs as part of a base offering for a machine.

Separators: As we enter the world of separator materials, impact-absorbing foams and other R2R battery materials, things are not as clear-cut. In addition to slot-die, these processes use any number of coating methods, from gravure and Microgravure®, to knife-over-roll, roll-over-roll, comma-bar and others. While modular coating heads make it such that a manufacturer can switch out different coating heads within the same equipment line, they generally cannot solve the issues presented by the general specifications, things such as drastic width, tension and speed differences (see Figure 3).

Why standardization is important

Taking a step back, we can examine why standardization is important to the industry as a whole. As R2R battery converters begin to move their processes from lab and benchtop operations into the world of continuous web processing, it is important to understand the lead times associated with custom equipment. While each manufacturer is different, most reputable machine builders are incredibly busy in this global economic environment. This, coupled with supply-chain issues largely centered around the drive and control systems needed to make these machines worth more than a penny a pound, is resulting in lead times from date of order placement to fully installed and commissioned equipment of anywhere from 12 to 18 months. For many converters, this blows through the window of opportunity that they have to bring a product to market.

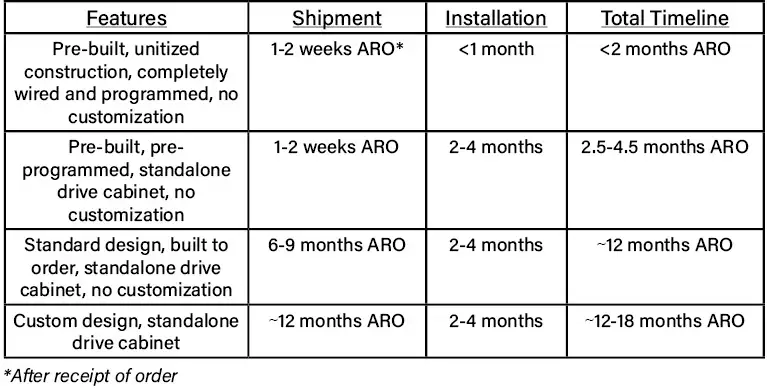

There are standard-equipment designs that allow for compressed timelines from order placement through installation and commissioning. For all the reasons outlined above, these typically are not a good fit for R2R battery converters, but Table 1 shows an outline of what these could look like in comparison to fully custom equipment.

Land, plug and play

The first example in Table 1 is equipment designed completely pre-wired to machine-mounted drive and control cabinets, allowing installation to consist of landing the equipment on the factory floor and dropping utility connections to it. Building larger machine lines in this manner adds a lot of cost upfront to the control system and requires multiple utility drops for individual machine sections. For smaller, pilot-scale equipment lines, particularly those where all sections are on one unitized base, this approach becomes more viable. In a perfect world, this machine could be ready to ship when an order is placed and be installed and commissioned in a few weeks.

More typical for larger coating and laminating lines is equipment that is prewired within each machine section but has a standalone drive cabinet. Even if this type of equipment was sitting on the shelf at a machine supplier, which is highly unlikely given the variables previously discussed, it still would take between 2 to 4 months to install, startup, commission and be in production. Another scenario would be that a machine builder had a design that was mostly standard and ready for production once an order was received. As soon as the order was placed, the equipment vendor would release component parts for purchase and assemble them upon arrival. While far better from a lead-time perspective than a custom-designed machine, this would still result in a 6- to 9-month deliver from receipt of order until shipment. Tack on another 2 to 4 months for installation and commissioning, and R2R converters need to prepare for approximately a full year from date of order placement until they can begin producing material. As you can see, lead times quickly grow, and end-users still are getting what is available, not necessarily what is optimized for their process.

As shown in Table 1, installation can be the limiting factor on the timeline for a lot of these options. There are some manufacturers who can include prefabricated installation materials to cut down on the installation time. Other options allow for a large portion of the install work to be pre-done during the equipment build cycle, which also may reduce the schedule.

Conclusion

There is no perfect solution for the challenges the R2R battery market will throw at converting-machinery manufacturers, but that doesn’t mean steps can’t be taken to reduce lead times. In the case of standard equipment, while it may not offer converters all of the features or throughput they desire, they can be available quickly so that converters don’t miss a market opportunity and the ability to prove their products to clients. While custom equipment always will have long lead times, equipment builders can take steps – such as stocking common parts, using standard components and modular designs – to help reduce them.

For converters, remember that the weeks before the PO are just as long as the weeks at the end of a project, so start planning for a new line as early as possible, even if that is just identifying vendors for a future RFQ.

Paul Lembo, exec vp at New Era Converting Machinery, Inc. (Patterson, NJ), holds a Bachelor of Science from Bucknell University. He has more than 20 years of experience in the R2R web-converting field with multiple contributions to industry trade publications and associations. Paul can be reached at 973-413-4602, fax: 201-670-8867, email: paul.lembo@neweraconverting.com, www.neweraconverting.com.