By Tom Bezigian, principal consultant, PLC Technologies Film & Extrusion Consulting Co.

Since the development of polyethylene film in 1937 [1], advancements in film technology have been made that even the most foresightful would not have imagined. Multilayer films and composites that protect their contents for months and even years now are commonplace. Food waste is reduced in large part due to packaging. Electronics, building components and a myriad of other products used in everyday life are attributable to the advancements in film-making technologies.

Along with these advances have come consequences, such as solid waste and its resulting disposal issues, energy consumption and more. This article will summarize some of the advances made in film technologies, some challenges posed by films and solid waste, and solutions and outlook for the future. Excerpts from interviews with those who are shaping the industry today will be presented.

Introduction

![Figure 1. Sample 5-, 9-, and 11-layer coextruded film structures available in the marketplace today [4]. Note the absence of chlorine in these structures.](https://convertingquarterly.com/wp-content/uploads/2025/02/cq321bezigian-FINAL_Fig1.webp)

It seems that the old adage, “What goes around, comes around,” still is true today. What used to be a truly circular economy, i.e., when farm to table truly existed, was changed with the development of cellophane film in 1908 [2]. Cellophane was a mainstay of DuPont’s business for years until polyethylene and other polymers unseated this naturally biodegradable film.

Films provide many functions, such as product protection; toughness; heat-sealability; vapor, moisture, grease and chemical barrier; light barrier; UV protection; electrical properties; printability and graphics; and much more. Blown-film and cast-film extrusion are the primary processes used to produce film.

It has been barely 85 years that “polythene” was developed by Imperial Chemical Industries in the UK. The name has changed slightly, and there now are hundreds of grades available for every conceivable application. The only differences between all grades of polyethylene are molecular weight (MW), MW distribution, density and chain branching.

There are thousands of mono-layer polyethylene blown-films line around the world, but this has been changing over the last 20 years or so. Multilayer films of more than 100 layers via coextrusion and lamination now are possible. In the late 1960s and early 70s, Walter Schrenk developed the Dow coextrusion feedblock [3]. The Dow feedblock is capable of producing flat films consisting of thousands of nanometer-thick layers. This development was a monumental gamechanger for the industry.

As the applications for coextrusion grew, the production of coextruded films increased to the point where hundreds of thousands of tons of coextruded films are produced annually. Where coextrusion fell short, adhesion lamination was used to combine layers into beautiful, functional and nearly indestructible composites. Then came the issue of solid waste; that is, where and how to dispose of the waste. Incompatible layers made these complex structures, which quite often included aluminum foil, nearly impossible to recycle.

Figure 1 shows representative 9- and 11-layer structures that commonly are used for fresh and frozen food packaging, as well as retort pouches. The repetition of layers of identical resins allows for substitution of higher-cost seal or abuse layers with lower-cost or recycled inner layers, as well as for improved barrier properties.

Soon it was realized that the cradle-to-grave paradigm was unsustainable. A new concept of sustainability arose, and the so-called “cradle-to-cradle” scenario was embraced [5]. Various US states banned certain plastic items, most notably disposable plastic retail-shopping bags. Public opinion, especially in Europe, has shifted from disposable products to more “environmentally friendly” products.

From this growth in worldwide concern sprang an effort to find a process, or sequence of processes, by which a single recyclable resin could offer product protection, durability, barrier properties and graphic arts, while also being sustainable. Several major corporations have embraced the Ellen MacArthur Foundation Pledge [6] to produce films which either are recyclable, compostable or biodegradable. With major players in the industry such as Mondi, ProAmpac, Coperion and more embracing sustainable technology as the future, others are following.

![Figure 2. Nine-layer blown-film coextrusion (Courtesy of Hosakawa Alpine [Natick, MA]), www.halpine.com/](https://convertingquarterly.com/wp-content/uploads/2025/02/cq321bezigian-Fig2-683x1024.webp)

Discussion

As mentioned above, blown- and cast-film extrusion are the primary processes used to produce film. Coextrusion is compatible with each process. As understanding of rheology grew, extrusion-die technology advanced. More and more uses for multilayer films then were developed. The benefits of coextrusion are that a composite film can be produced in a single manufactured step which possesses the properties of each discreet layer in a manageable, affordable, processable package.

There are physical and practical limitations as to the number of layers produced via traditional coextrusion. There is a limited amount of physical space in which to locate extruders, as well as a practical limitation as to the size and weight of the die and coextrusion assembly. From an engineering point of view, the longer the path length the melt must travel between the extruder and die exit, the higher the pressure required to pump the high-viscosity polymer melt through the die. This creates yet another limit to multilayer-film extrusion which acts as a limit to the number of different layers that can be coextruded.

A representative sample of machine suppliers, converters and industry experts were consulted in preparation for this article. The author spoke with Janevieve Parks, technical sales mgr.-INDEVCO Plastics of Longview, TX, about the substrate provider’s plans. “At INDEVCO Plastics [7], we are expanding our portfolio from industrial films to sustainable flexible-packaging films that will be produced in our new Orangeburg, SC, facility,” Parks says. “Our five-layer film line will produce machine-direction-oriented (MDO) PE films suitable for metallization or direct use in all-PE laminate structures to make fully-recyclable packaging, both barrier and non-barrier. Our nine-layer film line will produce sophisticated barrier packaging with the technology to also be fully recycle-ready” (see Figure 2).

![TABLE 1. Comparison of relative advantages of adhesive vs.

extrusion lamination [8]](https://convertingquarterly.com/wp-content/uploads/2025/02/cq321bezigian-Table1.jpg)

Lamination

Adhesive and extrusion lamination are available to combine films that cannot be otherwise manufactured, such as foil laminations. Each laminating method offers its own unique advantages. In comparing various factors such as those shown in Table 1, adhesive lamination clearly is the more sustainable method.

Each of the factors in Table 1, except for line speed and efficiency of long runs, indicates that adhesive lamination is a more sustainable production method. In particular, the last three traits in Table 1 illustrate that adhesive lamination is preferred in the circular economy due to its reduced carbon footprint.

In summary, it can be said that adhesive lamination offers a wide degree of flexibility in product capabilities at extremely low adhesive weights (see Figure 3). This is particularly important in regard to global growth of “sustainable” products, especially in packaging materials. Extrusion lamination offers high productivity rates and performance, and it is well-suited for long production runs. On the downside, extrusion lamination cannot achieve the low coating weights attainable with adhesive lamination. As will be shown, very low coating weights are extremely important to produce a sustainable film.

![Figure 3. An adhesive-lamination line for flexible packaging (Courtesy of Nordmeccanica Spa [Piacenza, Italy])](https://convertingquarterly.com/wp-content/uploads/2025/02/cq321bezigian-Fig3.webp)

So, now the quandary arises. We have films that preserve and protect for years. But this very fact alone makes coextruded films unsustainable. What is the solution to this issue? Parks alluded to part of the solution in her statement above: machine direction orientation (MDO). The answer is a conjunction of three processes: blown film oriented via MDO, vacuum deposition with a suitable material and lamination of these webs with a sustainable technique.

MDO is a simple technique in which rolls moving at different speeds orient the film in-line (see Figure 4). There is little wasted energy needed to accomplish this, and the properties imparted to the film are dramatic. MDO aligns the polymer molecules in a configuration that is similar to more-crystalline materials. The closer the polymer chains, the better the barrier and strength properties. If several different polyethylene layers are coextruded, then blown into a film and oriented via MDO, a sustainable film has taken the first step into creation.

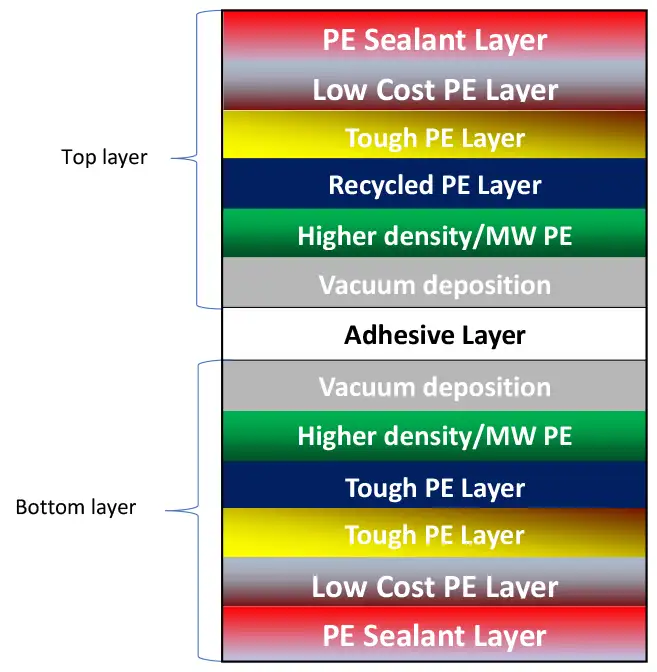

The next step is vacuum deposition for barrier protection. The vacuum-deposited layer (also known as metallizing) can be aluminum, AlOx (also referred to as ceramic), or SiOx [9, 10]. The vacuum-deposited layer has basically zero thickness and weight, and the dry adhesive weight is just a few gsm. Figures 5 and 6 illustrate two sample structures. Figure 5 is an MDO-PE film that has been metallized, primed, printed and then adhesive- laminated to a PE-sealant film. Figure 6 is a more advanced coextruded structure shown without printing.

The author spoke at length with Ginger Cushing, principal of G Prime LLC, about sustainable films, focusing partly on the challenges facing film suppliers and brand-owner customers in achieving their commitment to the Ellen MacArthur Foundation Pledge. “Sustainable package design involves significant liquid-coatings innovation, especially when it comes to the barrier properties needed to produce a packaged food with acceptable shelf life,” Cushing says. “While offering excelling moisture barrier, recyclable PE-based film structures need improved gas barrier. Bio-based film structures intended for composting often have good gas barrier but poor moisture barrier” [12].

![Figure 5. Sample of a sustainable, barrier-film lamination using MDO polyethylene [11]](https://convertingquarterly.com/wp-content/uploads/2025/02/Fig5.webp)

On the issue of achieving the high barrier level required for certain products, Cushing adds, “Vacuum metallizing combined with liquid coatings can be a powerful solution. The right primer will provide adhesion and smooth out a rough surface, which provides a suitable foundation for vacuum-deposited Al, AlOx or SiOx. Once applied, metal or ceramic surfaces can be fragile and a protective topcoat can assure the structure will survive the rigors of converting, package formation and storage. Regulatory legislation and raw material costs also present a challenge.”

Vacuum deposition

Metallizing, or vacuum deposition in general, is a well-established process which offers source reduction, cost reduction, flexibility and many other end-product benefits. The desire for sustainability has brought this technology to the forefront of industry attention. Because the technology is well known, nothing will be added in this article on the subject of metallizing, except to show the heart of the process and an overview of the equipment. Converting Quarterly has obtained rare photographs of the evaporation boats used in the vacuum deposition/metallization process. The entire process can be viewed at www.nordmeccanicaevents.com/events/1351/streams/161.

The author interviewed Andrea Glawe, regional sales dir.-KROENERT in Hamburg, Germany. When asked about trends, Glawe sees “new packaging trends with respect to recycling, sustainability and circular economy as well as packaging solutions for electronic products, such as flexible printed electronics and battery pouch-cells. Technology developments will integrate artificial intelligence into new machine concepts and become more energy-efficient and modular to be adaptable to growth and future needs.” Figure 8 shows a modular adhesive laminator.

Sustainability

The very word “sustainability” is nebulous to the scientific mind. It commonly is defined by government agencies, technical associations and other such groups. Then there is the scientific viewpoint. The equation for Gibbs Free Energy is well known:

EQUATION 1. G = U + PV−TS

Where: U is internal energy, P is pressure, V is volume, T is temperature, S is entropy, H is the enthalpy

This equation tells us that no matter what chemical or mechanical process is used in a system, energy will be wasted. This is because the Carnot Cycle does not exist in the real world. Wasted means energy that is given up to the system and cannot be recovered. The “system” is everything within the Earth’s atmosphere. This is a dismal thought.

![Figure 7. (Left) The evaporator assembly inside the vacuum chamber. (Right) Closeup of a single evaporator boat. (Courtesy of Nordmeccanica Spa [13])](https://convertingquarterly.com/wp-content/uploads/2025/02/cq321bezigian-Fig7-1024x285.jpg)

This brings me back to the first paragraph of the introduction and the circular economy. The circular economy existed before the Industrial Revolution. It (the circular economy) is similar to what one sees in a rural European village even today…on Monday mornings. Vendors bring their wares, unpackaged, to the market. Minimal packaging is used, and minimal energy is required to bring the goods to market. Cows grazing in the field and no use of fertilizers would go a long way to minimize CO2 addition to the atmosphere.

![Figure 8. A modular adhesive-laminating system (Courtesy of KROENERT [14])](https://convertingquarterly.com/wp-content/uploads/2025/02/cq321bezigian-Fig8.webp)

The development of the single-piston internal combustion engine during the late 1700s changed everything. Machines replaced horses, and the technology race began. Fast forward to today, with climate change in full gear, the future is uncertain. Plastic films definitely offer many benefits in terms of food protection, preservation, storage and scores of other positive benefits. They also simultaneously do less harm than the alternatives.

Summary and on the horizon

Sustainable films will become the norm. Look for many more blown-film lines and MDO upgrades, vacuum metallizers and adhesive laminators to be installed to meet the needs of sustainable films and future packaging structures. The elimination of vinyl and PVDC from the supply chain is essential for the future. Two-part / electron-beam-cured adhesives will fuel the modernization of equipment. Look to brand owners to enter the flexible-packaging market in a big way. On the technical side, we already have seen off-site technical troubleshooting, and artificial intelligence will add more to existing capabilities. The global COVID-19 pandemic has driven the need for this technology, and more is sure to come.

References

- https://www.globalplasticsheeting.com/our-blog-resource-library/bid/23095/The-History-of-Polyethylene#:~:text=The%20first%20patents%20for%20polythene,HDPE%20(High%20Density%20Polyethylene)

- https://www.forbes.com/sites/hbsworkingknowledge/2017/06/26/how-cellophane-changed-the-way-we-shop-for-food/?sh=7142dc482ad0

- US Patent No. 3,924,990

- Bezigian, Thomas; “A Review of Adhesive and Extrusion Lamination,” AIMCAL WCHC/SPE FlexPackCon 2015, Naples, FL, Oct. 2015

- https://www.cradletocradle.com/

- https://www.ellenmacarthurfoundation.org/

- https://indevcoplastics.com/

- Ibid No. 4

- http://www.idvac.co.uk/review-and-evaluation-of-alox-clear-barrier-production-processes/

- https://www.flexfilm.com/alox-coated-films.php

- https://www.bobst.com/uken/blog/detail/article/1611838980-transparent-mdo-pe-solutions-as-an-alternative-to-metallized-polyester/

- http://www.gprimellc.com/

- https://www.nordmeccanica.com/

- www.kroenert.de

Tom Bezigian, principal consultant at PLC Technologies Film & Extrusion Consulting Co., is a graduate of the University of Massachusetts at Lowell Plastics Engineering program. He has more than 40 years of experience in the industry and has worked in various capacities for companies such as Cryovac, Mobil Chemical, James River Corp. and Felix Schoeller GmbH. Tom then founded his own specialty film and extrusion laminating business, Great Lakes Technologies (Syracuse, NY), until he sold it to begin full-time consulting to the film & sheet extrusion and converting industries, serving many major clients around the world. Tom can be reached at 315-382-3241, tom.bezigian@gmail.com.