From the Web Handling Committee of the Association for Roll-to-Roll Converters (ARC)

Editor’s Note: This article is based on the introduction to the work-in-progress “Web-Handling Test Best Practices” document being finalized by the ARC committee. It ultimately will include sections on web-material properties, rollers, tension, nipped rollers, wrinkles, spreaders, guiding, wound rolls and other tests.

Disclaimer: While this document brings together many of what the ARC Web Handling Committee deems to be important best testing practices, it is by no means a complete collection of tests that can be used in the web-handling context. Additionally, no guarantees are stated or implied relative to the best practices included herein. The choice of test and the implementation thereof are the sole responsibility of the individual user of this document.

Introduction

All tests useful to web handling are not assembled into a single location. When tests are described in the literature, such as those commonly found in test labs, web-handling context and application seldom are mentioned. Those web-handling specific tests that are published have not been consistently described nor curated by a team of experts. This collection of web-handling best practices is intended to bring together a curated group of test methods, with specific application to web handling.

Means and Methodology

Each test primarily is the responsibility of a single author. As such, the Web Handling Best Practices function as a living monograph. The test author may be on the committee or in the community at large. The test author is to write up a proposal for a single test, then submit it to the wider committee for review during a short commentary period, and then incorporate those comments as the test author sees fit. New tests and updates to a test will proceed similarly. If the author abandons a test, it may be picked up by another author or by the committee at large. Author and version dates are included at the top of each test.

For ease of use, tests will have a standard format, very much like Smith’s Roll and Web Defect Troubleshooting. For ease of use, the test write-ups will be very brief: one page is the target, three is the maximum. When a suitable write-up exists, such as exemplified by Web Test 101 – Basis Weight, references may be all that are needed. When more than one option might be used, they will be grouped under the main test and numbered as exemplified by Web Test 801 – Wound Roll Diameter 801.1, 801.2, 801.3, etc. When too many variations might exist, only an outline of how the test might be designed and performed is given, as exemplified by Web Test 301 – Dancer Calibration, and all details then would be left to the service engineer. This overview approach, rather than spelling out details, will avoid difficulties for the author and user alike. This especially is true for situations where industry variation is large, such as for machine components like dancers and nips. This also is true for certain tests like curl where some test variations, in common use in industry, are not currently detailed in the literature.

Profile and Testing

Webs are neither perfect, nor perfectly uniform. The word ‘profile’ is shorthand for a variation of ‘____’ across the width of the web where ‘____’ can be any measurable or observable property. Two common examples are thickness profile, a variation of thickness (see Test 101) across the web, and basis weight (see Test 102), a variation of areal basis weight. It is not uncommon for the edges to be thicker or thinner that the rest of the web. Instead of requiring graphs or even measurements, we can describe those profiles as ‘frown’ or ‘smile’ shaped, respectively. Other common profiles include ridges, valleys and tapers. This is important for any test, including those for web handling, as you would get different values – answers, if you will – depending on where on the web the sample and/or measurement was taken. More about sampling next.

Of course, properties can vary down the length, MD, or with time as well. It is not uncommon for webs to be quite different in the first many minutes after startup. Even if QA ‘blesses’ the material at a certain time after startup, it still is likely to have more variability over the next hour than it will later in the run. MD or time-dependent variability often is less or even far less than CD variability. The fingerprint CD profile ‘shape’ of a web may be stable for hours, days or even for the life of a machine.

While not usually a direct concern for web-handling testing, concepts such as where in the web a measurement is made are not trivial, especially when the product proceeds to the next machine, such as a rewinder, which may remove material at the top and bottom of a master roll, as well as cut master roll into daughter rolls from different CD locations, as well as possibly of different individual widths. Those who want to learn more about traceability can view a series of YouTube clips on traceability with titles beginning with Web401.21a-g. Those wanting a bit more about sampling and documentation may wish to view Appendix S in The Web Handling Handbook.

Sampling and Testing

The tester must make two choices about sampling. The first is where across the width, CD position, of the web the sample is taken or the measurement is made. The second is the number of samples at any given CD location, which is the subject of the next section. This, of course, is a judgment that needs to be made by the tester if it is not already spelled out by local testing protocols. Common sampling for Quality Assurance (QA) is three or five measurements equally spaced or seven or more measurements equally spaced on wider webs. For example, five samples would be at the front edge, front quarter point, middle, back quarter point and back edge. However, a choice must be made as to where the ‘edge’ sample is taken. Typically, it is inside the saleable width a bit, but there are cases where you might measure outside the saleable width or much further inside due to edge effects of the sensor itself. Examples of edge effects of sensors include many online scanners as well as roll hardness measurements.

Statistics

Describing statistics is, for the most part, far beyond the intent of this brief guide on testing. However, a few generalities should be mentioned with regard to how many samples are needed to be confident in both the logical and statistical sense.

- For two reasons, always retain individual test values rather than compute and average and discard the original values. First, there is information in the individual values that can’t be reconstructed from the aggregate. The second reason is that data storage is super cheap. An example of poor protocol would be to sample five places across the width, compute the average and discard the individual values. Questions about CD profile could not be answered without those individual values should that need ever arise.

- Some tests are inherently noisy. Examples include web-web (see Test 115) or web-roller (see Test 206) COFs. Here it can be very difficult to tell where the variation is coming from. It could be the web material or the test itself. One can’t simply take the same web sample and repeat the friction test (to check for test variation) because every time you touch the sample you may well change its surface characteristics, perhaps noticeably. Increasing sample size will help both reduce and characterize variation, though at a cost.

- The number of samples required to be confident can vary enormously, well beyond the differences individuals might have in setting confidence levels. An extreme example is that a web break during a brief acceleration period may be sufficient to say that the tension control may be brutish during that challenging portion of a minute. That is because the web presumably runs for hundreds or thousands of minutes during steady state without a web break. At the other extreme, it can take the running of as many as 10,000 wound rolls to conclude that one paper supplier provides a less break-prone material than another. [Page, D.H. and Seth, R.S. The Problem of Pressroom Runnability. TAPPI Journal, vol. 65, no. 8, pp 92-95, Aug, 1982]

- Paul Frost has looked at sampling and testing and MD/CD variability in great depth with some quite statistically shocking conclusions. That is the sampling protocol in some test labs is insufficient to make some of the conclusions that might be useful, such as whether one roll is better than another. Even the online scanners that take thousands of measurements per roll are not immune because those measurements often are exceedingly noisy [The Application of Statistical Process Control to Web Products. TAPPI Polymers Conf. Proc., Sept 1989 and a self-published book by Paul Frost Associates].

- Testing, like everything else, is subject to economics. The quality of the instrument and the number of samples is, at best, a judgment call that tries to balance consumer and producer risk.

Environmental Conditions and Time

While web-handling tests may not always be as fussy as is a dedicated quality test lab, there may be a few things to consider. ‘Standard’ test conditions often are specified as 20º C and 50% RH. Conditioning and pre-conditioning also may be required to give time for the sample to equilibrate. TAPPI has as much or more to say about this subject as any. For example, TAPPI/ANSI 402 sp-21 defines environmental conditions for preconditioning (which is required for paper that is wetter than standard conditions), conditioning (as well as the time required) and testing. This especially is important for cellulosic materials, such as paper, because most material properties are sensitive or extremely sensitive to moisture content, thus RH and time.

There are other environmental conditions that may apply. In-situ testing may be preferred because it is the environment in which the web behavior takes place and because it is simpler. Behaviors taking place in hot ovens are much more challenging for testing. Finally, some material properties and thus behaviors can be noticeably time-dependent. An example is that the web-web COF (see Test 115) of some films can get lower with time due to migration of slip agents. Similar behavior is seen on some paper grades for unknown reasons.

Units and Unit Conversions

Almost all test values have units. Common exceptions include COF, ‘draw’ and web strain, all of which are unitless. All test values should include units when written and often when spoken. For example, web speed could be measured as 500 mpm. Only if there were no ambiguity, such as when speaking informally with an operator of a European-built machine, could one perhaps safely omit the units. In the US, there can be much ambiguity and inconsistency of units among machines and even on different sections of the same machine. Sometimes the displayed units are improper machine units, such as bar or psi of pressure on a dancer or nip, instead of PLI (pounds per lineal inch) or kN/m (kilo-Newtons per meter). Units can be no less confusing for test lab equipment. Often, a test instrument might not display units, and/or the units recorded may not be listed on a data recording sheet. Units could/should be in the machine’s or instrument’s instruction manual or in the original test write-up, if they can be found. If there were any doubt still remaining, one could calibrate or check calibration of the instrument – a best practice for other reasons as well.

Sometimes when the units are known, they may not be in the desired form or system. An example is if you were vacationing in the US and looked at the day’s weather forecast, you likely would see temperatures displayed in degrees Fahrenheit, rather than in your familiar degrees centigrade. The conversion factor is well known and easy enough. The formula can be found on the Internet readily or as a convenient Internet calculator: ? = 5/9(?−32)C=5/9F−32

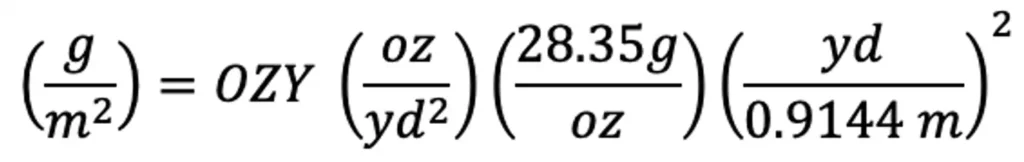

Other times, the conversion will not be as easy to find, and you may need to figure out the conversion factor yourself. Figure 1 is an example for converting one odd basis weight, OZY (ounces per square yard), used only in nonwovens and textiles in the US, to a more universal GSM (grams per square meter). While this can be found online, we will do this here as a simple illustration.

The user must first find the individual conversion factors, such as 28.35 g/oz and yd/0.9144m. Then one must check to make sure all units ‘cancel’ except the ones that one wishes to remain (g/m2). Finally, you can do the calculations to get conversion formula. As an extra check, you could go to a conversion utility (that may or may not always list the formula and certainly not the derivation): g/m2 = 33.9 X OZY.

The purpose of this example is not to teach unit conversion. Rather it is that if you can’t readily perform this type of operation yourself, perhaps because you never learned or since forgot, then it could be risky to use any conversion formulae or Internet calculators.

Because there are so many tests given here and so many possible conversions one might want to do between one set of units and another and in either of two directions, we will not provide them in the body of this text. As a brief concession, what we will do is provide some common conversion factors used for web handling in the appendix taken from The Web Handling Handbook, courtesy of Destech Publishing.

The ARC Web Handling Committee consists of industry experts who have demonstrated knowledge of web handling based on science and decades of practical application. Its mission/vision is to educate sponsor companies on web-handling best practices, connect members to discuss common challenges and potential solutions, grow the technical capabilities of the sponsor companies and foster innovation in web handling. More information is available at www.rolltoroll.org/committees.

Additionally, check out this valuable resource: www.rolltoroll.org/roll-to-roll-glossary