By Rob McNamee, business development mgr., Elite Cameron, Inc.

Abstract

Buying new slitting and rewinding equipment can be a daunting task, given all the options available in today’s modern equipment. It can be difficult to determine the best machine type for the application, as well as what features would provide the most benefit. Generally speaking, there are three main types of slitter/rewinders: center-winders, center-surface winders and surface winders. Within these are variations including single-shaft, dual-shaft and turret rewinds, and each type of rewinder has its areas of strength, so it is important to have a basic understanding prior to purchasing a machine.

Introduction

Converters who have experience with purchasing slitting and rewinding equipment have gone through the learning process of determining the right machine for their applications. However, because these capital investments are relatively infrequent and process requirements change over time, it sometimes can be difficult to determine the type of slitter that would work best for the process. It is helpful to have a good understanding of the three main types of slitter/rewinder: center-wind, center-surface wind and surface-wind. Each is given its name by the way in which it drives the rewind, and it is important to have a basic understanding of each to recognize which type will be most beneficial for the application.

Center-Winders

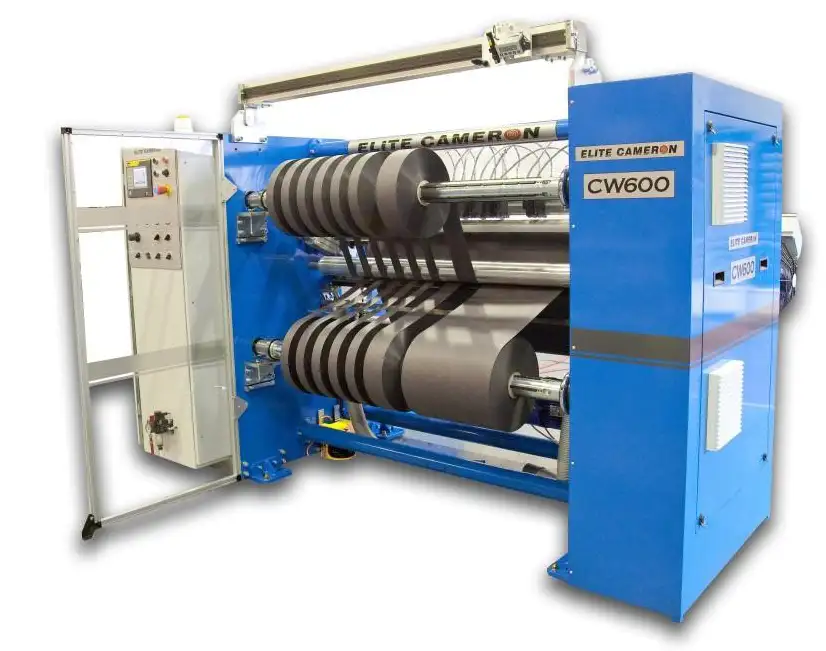

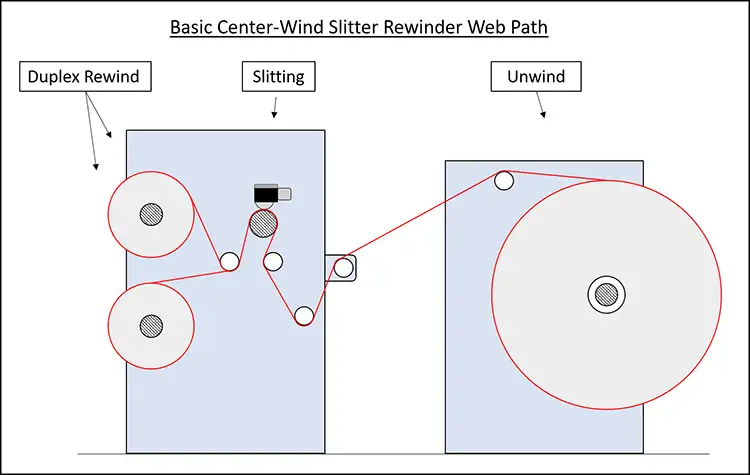

Center-wind slitter/rewinders, or “center-winders” for short, are an increasingly common type of slitter for a variety of converters. As its name suggests, the finished roll’s rotation is driven through the center by the rewind shaft from the engagement between the roll’s core and the shaft. A center-winder normally will have one or two rewind shafts, but it may have more in turret configurations. A single-shaft configuration commonly is referred to as a “simplex” winder, and a dual-shaft configuration is called a “duplex” winder. In a duplex machine, the shafts are in the same vertical plane, one above the other (see Figure 1).

Simplex center-winders typically are used in log-winding applications, or where the slit rolls do not require differential winding. Because there is no differential winding, an airshaft normally is used to lock to the core(s), and the tension is controlled by the torque of the motor through a clutch.

Duplex center-winders are arguably the most common slitter/rewinders used by converters. The slit webs can be rewound alternating between top and bottom rewind shafts, creating separation and preventing interleaving (see Figure 2). This configuration also allows for differential shafts to be used to ensure good tension control and rewind quality. This is especially important for materials that may have caliper variation across the width, which will cause the finished-roll diameters to build at different rates, and thus, create tension variations between rolls. Differential shafts help to mitigate this issue by allowing rolls that build faster to slip, therefore maintaining tension and preserving roll quality.

General characteristics: Duplex center-winders normally will have a maximum rewind diameter of 32 in., and simplex machines can rewind slightly larger. Some manufacturers provide 40-in. duplex machines with roll-ejection systems for unloading, though it should be noted that rewind diameters above 32 in. may present ergonomic challenges because of the height of the top rewind shaft. These machines can range in width from narrow benchtop machines to ones up to 90 in. wide, depending on roll weight and shaft sizes. The average web width for many converters is approximately 60 in. (+/-12 in.). The maximum speed of these machines normally will range between 1,500-2,000 fpm, with the appropriate shaft-bearing arrangement. The minimum slit width is normally above 1 in., depending on product stability and running factors. These machines also may have turreting capabilities, where the inboard shafts are winding while the outboard shafts are being unloaded and re-cored for the next run.

Center-Surface Winders

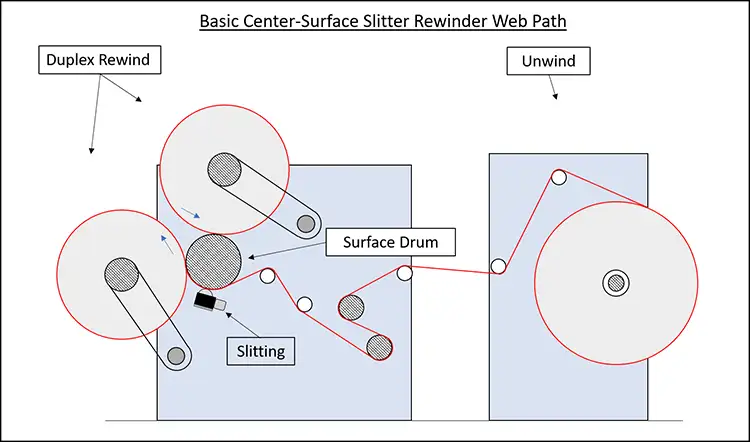

Center-slitter/rewinders are another popular style of equipment for converters. In this machine, the finished rolls are driven at both the center, by the rewind shaft, and at the outer diameter, by the “surface drum.” The shaft or shafts are mounted on rewind arms that pivot away as the roll builds in diameter (see Figure 3).

The drive from the center of the roll is much like the center-wind machines previously described. The drive at the outer diameter is the contact between the drum and the material. For modern machines with this configuration, the nip pressure between the rolls and the drum is adjustable, with higher nip pressures creating “harder” rolls and lower pressures creating “softer” ones.

These machines also can be designed to run in a mode called “minimum gap,” where the rolls do not contact the drum, but maintain a set distance even as the roll builds in diameter. This mode is considered center-winding, but the configuration of the web path will provide more support than the standard center-winder. This is well-suited for products that are sensitive to contact or require differential rewinding.

Because the rewind can be driven in two places, the tension can be more finely controlled, which allows the center-surface machine to process delicate, stretchy and, otherwise, difficult-to-wind materials. In addition to this, the web path for this style of machine ensures the material is fully supported from the slitting section to the rewind (see Figure 4). Once the material has been slit, the section from the knives to the rewind is where the web is the most vulnerable to movement or breakage. Without the support that a center-surface machine provides, it would be difficult to produce good rewind quality, especially at slit widths below 1 in.

General characteristics: Typical center-surface machines either are simplex or duplex and have a rewind-diameter capacity up to 50 in. Because the rolls can be supported by the surface-drum, the machine can support heavier rolls at wider widths than a center-winder with the same shaft sizes. As mentioned before, the configuration of the web path supports the web up to the rewind, making it ideal for delicate materials and slitting/rewinding narrow widths (<1 in.) to large diameters.

Surface-Winders

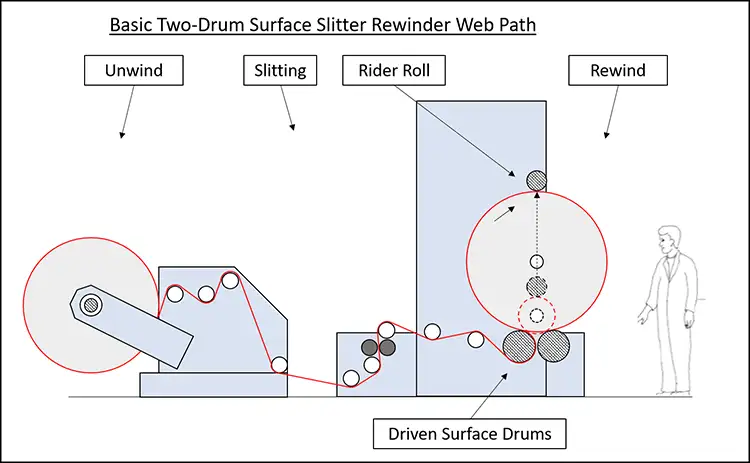

The final major type of slitter/rewinder is the surface-winder (see Figure 5). This machine has been a popular style for large-scale paper, textile and nonwoven applications where wide-width, large-diameter and heavy roll-weight capacities are required. In this mode of rewind, the finished roll is driven only by the outer diameter, or surface, of the roll. From this, there are multiple configurations, but one popular arrangement is the two-drum surface winder (see Figure 6). In a two-drum winder, the rewind roll rests between two driven cylinders called drums with a third “rider-roll” that pushes downward from the top of the roll. As the material builds in diameter, the rider roll raises and applies a programmable nipping pressure.

These machines generally have a greater overall footprint to support larger roll sizes. Because the rewind roll is fully supported from the bottom, the machine is well suited for winding at high speeds. This is important for manufacturers that need to produce bulk rolls efficiently.

General characteristics: Two-drum surface winders normally have a rewind diameter up to 80 in., but they have been known to be even larger. These machines also are known to have a larger footprint, with widths up to 160 in. and rewind-weight capacities of several thousand pounds. They are designed with heavy-duty side frames for high-speed winding with web speeds up to 6,000 fpm.

Summary

Each of the machine types have their areas of strength; aligning those strengths to the application requirements is critical to success. Once the rewind style is determined, machine features, such as slitting and shaft type, can be defined more easily.

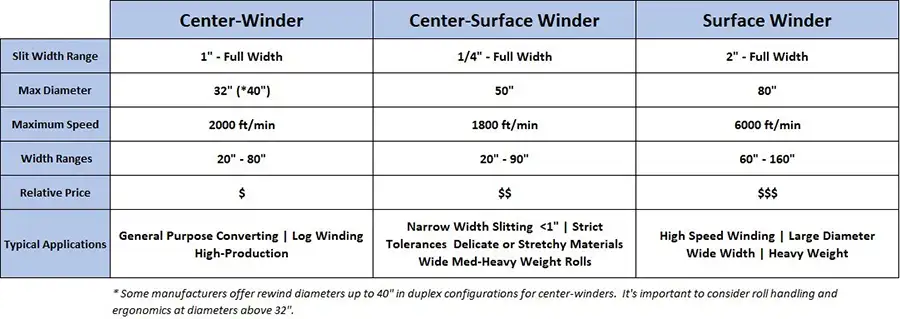

Table 1 offers a general outline of machine types, their main differences and typical applications where they are used. However, as the converting industry is broad and machine designs vary between equipment manufacturers, the table should serve only as a general reference. More thorough discussions are needed to be certain the right machine is specified.

Conclusion

Armed with a better understanding of the three main types of slitter/rewinders, converters will know the right questions to ask and discuss with the machine manufacturer. Through these conversations, they can feel more confident that they are selecting the right machine outfitted with the right features for their application.

Rob McNamee, business development mgr. at Elite Cameron, Inc. (Windham, ME), holds a Bachelor of Science in Mechanical Engineering from Worcester Polytechnic Institute. He has over 10 years of technical sales experience, the last four of which have been in the converting industry. McNamee oversees North American sales to create partnerships and develop custom-equipment solutions for converters in need of slitting/rewinding, laminating, hot-melt coating and core-cutting equipment. He can be reached at 207-894-7016; email: rmcnamee@elitecameron.com, www.elitecameron.com.