By Ron Lynch, president/owner, R J Lynch & Associates

After almost 50 years involved with web-handling and consulting, I have seen a few mistakes. I must confess, for the first 15 years, I was an untrained hack and made many of them myself. Here are some of the mistakes I have seen and made as they relate to dancers & accumulators, as well as web guides, along with suggested solutions.

Editor’s Note: This technical article won the Web-Handling Committee Best Paper Award at the AIMCAL R2R USA Virtual Conference that was held online in October 2020. Part 2 of this article – in the 2021 Q3 issue – will cover bowed rollers, idler rolls and driven rollers.

Dancers and accumulators

Dancers and accumulators are two of the more important systems in a web path but often are the least understood and most neglected. These can be large festoons to support splicing or small dancers to control tension at an unwind or locally in a process.

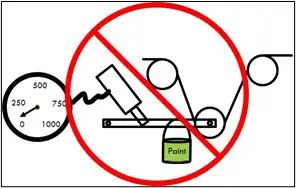

Uncalibrated and poorly calibrated systems are common mistakes (see Figure 1). These take the form of adjustments that have no measurements or are poorly labeled. Examples are a weight that can be slid along the arm without any measurement or trying to set 3 psi on a 0- to 100-psi gauge calibrated in 5-psi increments. Another problem is readings in percent or psi where there is no calibration between the reading and the tension in the web. Without accurate measurements and adjustments, it is difficult to fine-tune any web-handling system or duplicate a lucky success.

A large web-angle change as a dancer arm moves indicates a poorly designed dancer. The web’s entry and exit spans should remain roughly parallel to each other and perpendicular to the arm or carriage as the dancer or accumulator moves. If the angles are changing, the tension is changing, so the calibration is correct at one position only – which may or may not be the normal running position. None are perfect, but plumb, square and level seems to be a good design philosophy for dancers and accumulators.

Another mistake is making “undocumented” changes to a dancer system to increase or decrease tension, but without changing “official” setpoints. I believe this is done because the “official” targets for setup don’t work, and people find unofficial ways through trial and error to make the system work. Or maybe the right parts just weren’t in the storeroom. Ad-hoc changes that don’t make it into “official” documentation can cause only problems with subsequent machines and production.

Binding cylinders, pivots and slides cause poor tension control and are an indication of neglect. Without regular inspection and maintenance, rust, dirt and lack of lubrication will cause problems eventually. The visual clue is jerky motion of the dancer or accumulator. Some gentle, low-amplitude oscillation of the system is normal, but jerks or exaggerated swings are an indication of problems.

Dancers and accumulators are sensitive to alignment. Because of the multiple moving rollers, even small amounts of misalignment between the stationary and moving rollers can cause significant mistracking as the device fills and empties. The misalignment can be well within tolerances to avoid wrinkles, but any alignment error can cause tracking change as the span lengths increase and decrease.

Overly large, high-mass moving parts in dancers and accumulators, and high-mass idlers cause tension transients during speed changes and splices. Too massive a design forces lines to run higher tension or slow down just to avoid breakouts and slack during splices. On the other hand, too light a design results in deflection that leads to wrinkles and mistracking. Components need to be sized to avoid excessive deflection under the expected range of tension, but no bigger to avoid mass-related transient problems.

Web guides

A web guide is a common piece of equipment. Smaller offset-pivot guides and steering guides for narrow webs seem to have the most problems. I believe this is because they are small, sometimes installed and maintained on-site, and are not engineered and installed at the original equipment manufacturer.

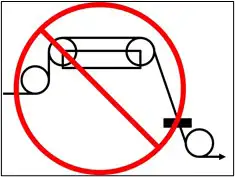

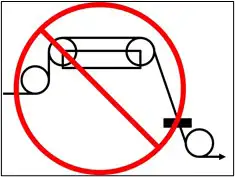

The most common mistake I see is the sensor mounted at the downstream end of the guide’s exit span (see Figure 2). With the sensor in this location, the guide’s controller gain must be turned down to prevent overshoot and oscillation. The turndown is done either manually or as the consequence of the auto-setup function of the guide’s controller. In some cases, an operator just turns the guide off to stop the oscillation. Whichever way it may be done, the result is the same: The guide is slowed down or inoperative, and tracking quality is degraded. The farther downstream the sensor is from the guide, the slower the guide reacts. The sensor needs to be as close to the guide’s moving exit roller as possible for all types of guides.

Short spans and incorrect angles are another problem often seen with web guides. Offset-pivot guides mostly twist the web, and steering guides both bend and twist the web. For both types, short lengths and incorrect angles make the web more likely to wrinkle and can cause even more mistracking in the web, thus making it harder or impossible to control.

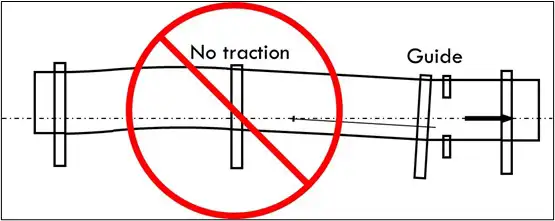

A problem I’ve seen with steering guides is insufficient traction on the roller upstream of the guide. When the guide bends the web, the upstream roller must anchor the web to keep the bending from traveling into its upstream span. If the web slips on the upstream roller, the bend travels upstream. This is called “moment transfer” (see Figure 3). When this happens, the bend pushes the web more in the mistrack direction. The guide then has to move more in the correction direction; this makes more bending traveling upstream and the web moves even farther in the mistrack direction. The result is the web runs off in the mistrack direction, the guide runs to its limit of travel in the correction direction, and correction is no longer possible.

Many adjustments and rules must be satisfied to achieve good web-guiding performance. The bottom line is to read the manuals and follow the rules for all types of guide systems. It is the best way to avoid mistakes with web guides.

Costs and schedules are not solutions

Cost and schedule are why you work on something, but they are not where the solution is. I see companies hire new engineers and assign them to track quality statistics and downtime, run team meetings, set priorities, make budgets and make lists of things to work on. Consequently, those engineers define problems in terms of cost, schedule and staffing. These things are important, but you quickly need to turn to observation, hypothesis, testing and data collection to identify and actually solve a physical problem.

But on the job, I often see that engineers don’t get training in web-handling, troubleshooting and equipment, nor the management guidance to do that kind of work themselves. Problems often are left to others to solve by “guess-and-try” methods, leaving the root cause and robustness of the solution unknown.

Maybe it was a 1980s or 1990s thing, but it seemed like some “expert” would write a book, and suddenly there was an in-house guru preaching and teaching a new project management technique, product quality methodology or Xeroxed troubleshooting templates or putting blue tape on the lunchroom tables so we knew where to find the salt and pepper. I don’t miss those days. I spent my time preaching and teaching web-handling. The troubleshooting templates and blue tape are long gone, but web-handling is still around.

Web-handling is not a fad. It is a science rooted in Hook’s stress equals strain times modulus and Newton’s F = ma. Web-handling skill, not management fads, is what makes the machines run. You don’t need fad managers – you need trained web-handlers who can and want to do it and are enabled and valued by management.

Conclusion

As a web-handling trainer and consultant, my goal is to have people not make these mistakes. There is no substitute for having trained, willing and empowered employees to avoid and solve web-handling problems. Anything less is a mistake.

Ron Lynch, president/owner of R J Lynch & Associates, holds a Bachelor of Science in Mechanical Engineering from the University of Cincinnati and is a registered Professional Engineer. He worked 39 years for Procter and Gamble, with 36 of those years working with web products and web-handling. In the early 1990s, Ron became the in-house web-handling trainer and consultant for P&G’s web-based products and their equipment and web suppliers. He has conducted more than 200 classes and trained over 3,000 engineers and technicians on web-handling in 10 countries on four continents. He was the principal instructor for the Basic Web Handling Seminar at the Web Handling Research Center at Oklahoma State University from 2000-2019. Today, R J Lynch & Associates provides web-handling training and consulting services for clients. Ron can be reached at 513-503-5160, email: ronjlynch@hotmail.com.