By Carles Masgrau, technical manager and co-owner, Synaptik Lamination SL

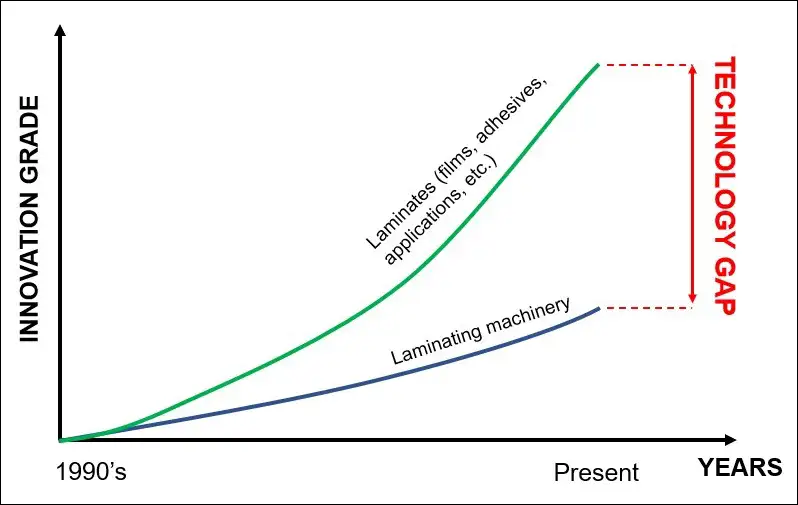

The chemical industry within flexible packaging has evolved in the last 20 years, but the technology in laminating machines has not evolved in those same 20 years. This difference creates a technology gap, and it has led to a situation where the products that are laminated are very expensive; therefore, the waste due to human error also is very expensive. On the other hand, laminating machines continue to require manual adjustments in a sector where it is very difficult to find well-trained operators, which causes issues with customers. New technologies are appearing that make this technological gap smaller by turning laminators into machines that are less dependent on the human factor.

Introduction

In 1998, I started to automate laminating machines for the flexible packaging industry. It was an interesting time in automation, with the evolution of AC-motor controllers, remote units for PLCs and, above all, the industrialization of touchscreens. All these technical advances allowed lamination machines to make great progress in terms of automation, thus making operator tasks much easier.

I can say unequivocally that there was an enormous difference in terms of automation and dependence on the human factor between a machine from the 1990s and one 10 years later, at the dawn of the 21st century. But, can I say the same if comparing a laminating machine from the turn of this century to a machine today? The answer is no. True, there have been improvements with more colorful interfaces; they’re easier to use, have improved data collection and so on; but, in what matters most, there has been no progress in terms of an increased level of automation and less dependence on the skills of the operator. The machines still are very dependent on manual adjustments and, therefore, very sensitive to human error.

On the other hand, in these last 20 years, the lamination sector within flexible packaging has evolved a great deal; multilayer flexible packaging has flooded supermarket shelves everywhere with products that two decades ago would have been unimaginable to see packaged in flexible plastic as they are now. And, the growth forecast for the next few years remains high. All this has been thanks to a great technological leap forward in both flexible plastics and adhesives, as the chemical industries have done their homework and done it well.

The technology gap

This technological evolution of plastics and adhesives has brought an important revolution to the packaging industry, but it also has led to two complications in the lamination process within the converting industry:

- These new plastics, with great barrier and physical properties, are logically more costly than plastics with fewer properties. Currently, the cost of a product that comes out of a laminator during one shift can range from $30,000 to $55,000.

- More difficulty in the lamination process, laminating barrier or metallic films is much more complex than two standard OPPs, for example. Laminating for retort packaging would be another example, as it requires new-generation adhesives, with chemical properties that can complicate the lamination process.

But the technological strides made by the chemical industry have not been proportional to the technological advance of laminating machines, as I explained above, which is a difference that I call the technology gap (see Figure 1).

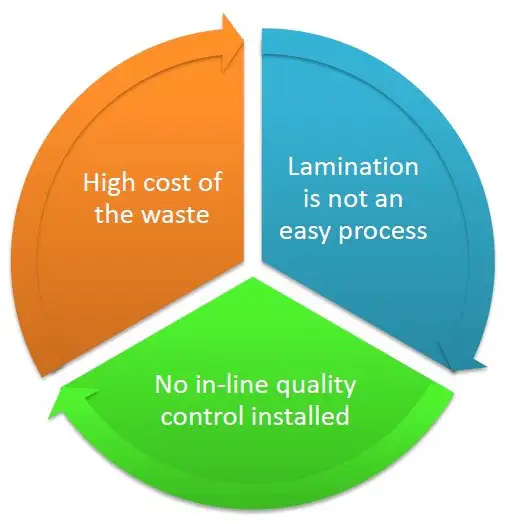

My previous article (2019 Quarter 2) talked about what I call the Trouble Circle (see Figure 2), where the operator is under pressure to make adjustments for a job in which one mistake on his part is a very costly one. Operators generally lack quality-control elements on the line; nor do they have a level of automation to help reduce their reliance on them.

Therefore, the Trouble Circle in which operators find themselves has become more dramatic. The cost of the product they handle is much higher, the process is trickier and they are using a highly manual machine that depends too much on their skills.

I have visited hundreds of customers all over the world, and each country or region has different problems, but if we focus on Europe and especially on North America, it is exceedingly difficult to find and retain good machine operators. In many cases, operators with less than a year’s experience are on the lamination machine, with little knowledge of the process, as they have not had time for proper training or to gain experience. The turnover is very high. But, one mistake on the operator’s part can cost hundreds of thousands of dollars – too much pressure for an inexperienced operator and too much risk for a company.

The growth of flexible packaging also has led to a huge increase in production in the lamination process, thus increasing the need for skilled operators in these processes, which there really aren’t enough of…

We are in the era of artificial intelligence and machine learning. We are able to make self-driving cars and access virtual assistants. The technology exists – we experience it every day. Why this technology gap? My experience leads me to believe that there are two reasons:

- Machine manufacturers are companies created in the second half of the last century with a very mechanical tradition in which a greater emphasis always has been placed on mechanics rather than on automation and software. There is no doubt that these machines have extraordinary mechanics and that these companies are full of highly knowledgeable mechanical engineers, but I believe that mechanics is not the way forward in this new industrial revolution.

- The level of investment that many converters allocate to machinery in the lamination process traditionally is low, and machine manufacturers have devoted more effort to reducing costs and efficiency in the production processes than to advancing technologically. This has led to converters not allocating much investment in this process, since it has not progressed much technologically either, so they see no point in investing further in it.

Reducing the technology gap

Could we reduce this technology gap and minimize the Trouble Circle? Let’s examine the two reasons I discussed for the technology gap.

Emphasis on automation

Regarding the first point, the good news is that the technology exists. Companies have appeared in recent years that have created various accessories and software that complement the good, original mechanics of the machines, considerably reducing the dependence on human operators and the risk of human error by making the adjustments more automatic and less manual. Let’s give examples.

More than 60% of waste in the lamination process is due to not applying the right amount of adhesive or the wrong adhesive-mixing ratio. If we look at a solventless laminator, the operator must manually enter the speed % on the feed rollers to choose what amount of adhesive will be applied, according to what the quality department has indicated. And, how does the operator know which speed % to choose? Well, it depends on the operator’s experience and the training received. So, we now have a big problem – the dependence on the operator’s skills for the most important settings on the machine.

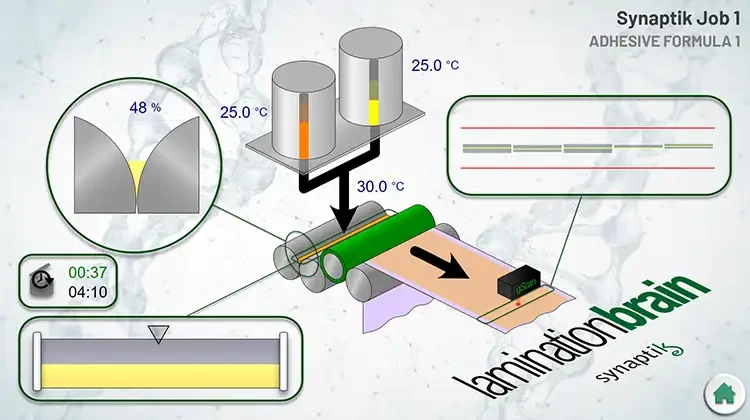

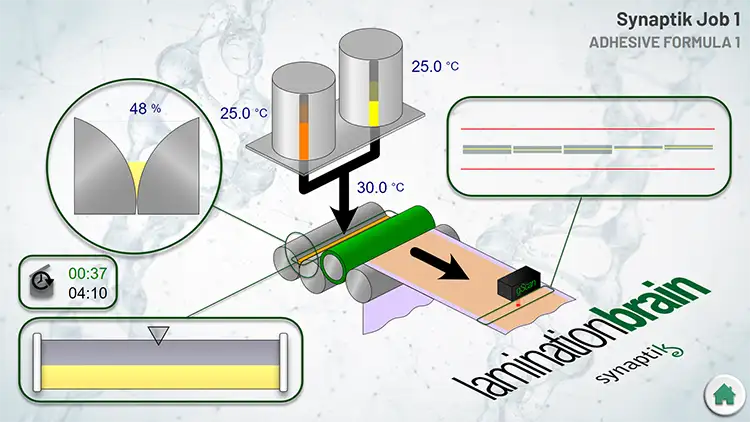

This process, which causes companies to lose hundreds of thousands of dollars, can be solved by installing an online scanner for the detection of the applied coating weight (see Figure 3), where an error instantly is reported, and the operator can stop the machine or act on it to fix the problem. Or, to reduce the dependence on the operator, automatic-control software can be installed, so the operator or the quality technician only will have to enter the desired adhesive coating weight and the machine then adjusts automatically, with no manual intervention.

Another example is in adhesive application. The market trend is to try to reduce the time-to-market as much as possible. This involves the use of fast-curing adhesives, which allow the laminated rolls to be slit as quickly as possible and then sent off to the final customer. Standard lamination machines for solvent-free adhesives are not set up to ensure that the adhesive that is applied is always fresh (i.e., the mixing of the two components has been made less than a minute before being applied) and properly distributed along the entire lamination width. This problem can be solved by installing an external device that controls the level and distribution of adhesive applied by the machine, depending on the production speed and the coating weight applied. This lets operators work with fast-curing adhesives without delamination problems and greatly reduces the emission of harmful vapors. Therefore, the technology to reduce this technology gap exists now and is implementable.

Investments in lamination

If the focus shifts to the second point in the reasons for the large technology gap, the levels of investment in lamination machinery is low when compared to the cost of the product that the machine is producing. This, as I have said, results from the excessive emphasis on reducing costs to be able to offer low machine prices, rather than moving forward with automation. Since the technology exists to reduce this dependence on the operator’s skills, it all comes down to converter companies being aware of these technological advances, doing the calculations to see the rapid ROI of these technologies and then expanding their investment budget in the lamination process.

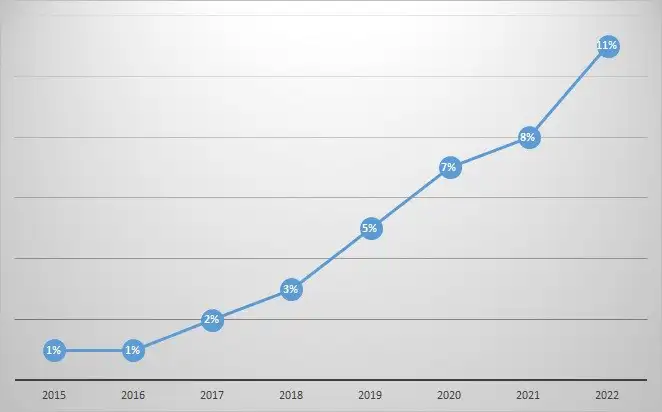

There is a rapidly rising number of laminators on the market with these new technologies, although the percentage still is small. Figure 5 shows the % of medium-high performance laminators with a scanner to read the applied adhesive coating weight online is growing; although it still could be considered “low,” the upward trend suggests that in a few years it will reach at least 30% of laminators.

Conclusion

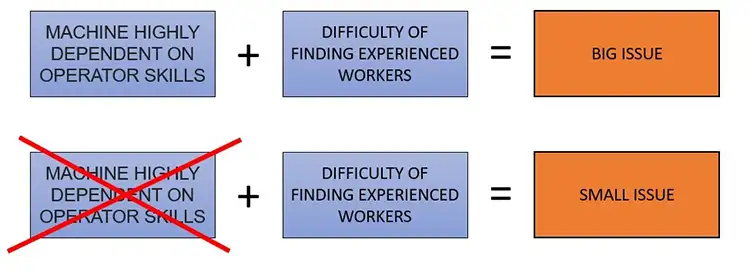

In summary, we find that one of the biggest problems facing the converting industry is the difficulty in finding experienced operators. This is a very big problem that our customers have to deal with, given the fact that laminating machines still require a great deal of manual adjustment. The emergence of new companies that design and manufacture equipment to reduce this dependence on the skills of operators is helping to solve this problem (see Figure 6).

The technological strides made in flexible plastics and adhesives have made the lamination process more complex, accompanied by an increase in production, making it impossible to find sufficiently trained operators and creating a problem in this industry. The emergence of new companies aimed at creating accessories to minimize the dependence on operator skill in this process is reducing this problem, and although fewer than 10% of laminators have this equipment, the trend is toward exponential growth.

Carles Masgrau, technical manager and co-owner, Synaptik Lamination SL, has been in the flexible packaging industry for more than 25 years and worked as an R&D project manager in coating and laminating before becoming technical manager and co-owner of Synaptik Lamination SL. Masgrau can be reached at email: cmasgrau@synaptik.cat, www.synaptik.cat.