By Giancarlo Caimmi, Ph.D., commercial director, Nordmeccanica Group

The development of algorithms replicating the selection of machine settings and process control, powered by AI, may bring significant advantages to the converting industry. These include uniformity of machine settings, simplification of operator training and improvement of machine up-time.

Artificial intelligence (AI) uses are growing within our day-to-day lives as consumers. From cellphones to TV sets to cars, AI applications constantly are on the rise. AI applications in the business world, however, are less invasive. The need to tune AI to specific uses is definitively one of the causes as the investments needed for the R&D behind such applications may reach levels feasible only to large software organizations. These organizations obviously are targeting areas of the market that will result in a fast return for their investments. Consequently, the first industrial applications have been seen in logistics, production-process management (material handling and flow management) and the like, and the standard available software packages can be upgraded only with reasonable levels of customizations.

The application of AI to the management of equipment in general, and converting equipment in particular, is a different story. I refer to something similar to applications implemented in the automotive industry: Cars driven by AI, without human supervision. Projects of that nature have been under development for years now, with only partial implementation to date due to the complexity of the task. The same complexity applies when talking about industrial equipment, especially for those applications where the operator’s job is crucial to the quality of the final output, as is the case with converting equipment. Printing presses, coaters and laminators all require trained personnel, with know-how and experience, to run production. But, even those applications can be targets for AI.

The question is: Can a converting machine be driven by AI? That is the R&D route the company I work for started investigating a while ago.

Justification for AI R&D

A converting process in general, and coating and laminating processes in particular, is very complex to govern. The combined contribution of properly engineered equipment and the experience of the converter/operator is at the base of the quality of the outcome.

Machine technology nowadays has greatly evolved toward reliability and ease of use. Decades of technical developments allowed the industry to master process handling. Advancements in electronics and mechatronics have made modern equipment easier than ever to run for an operator through machine set-up and production-run supervision.

Consequently, we may state that process handling these days is easier, but what about the selection of and decision on proper machine settings for a specific job? This step remains heavily influenced by human knowledge and experience. It is the selection of technical inputs that are vital to the quality of the production process. The experience and ability of the operator make a difference.

It is obvious that the application of AI to process handling may bring significant advantages. In this case, the target is the selection of machine settings in an automated process and the follow-up in process control during machine runs. Let’s consider the time required to train a new operator. Several pieces of information are provided to the new employee – first, how to use machine controls and then how to handle the decision-making process on specific settings. Operator ability will grow with time (and obviously, errors), only to know that one day the operator may decide to change jobs, leaving the company and taking with him or her a wealth of knowledge that should be the employer’s property.

Consider the benefits of potential uniformity in machine settings that Artificial Intelligence may provide to benefit the quality of the final output. Then consider the potential machine up-time increase provided by a speedy and automated decision-making process. This is enough to justify the R&D required to develop a technology based on AI to take care of these tasks.

Applying AI in manufacturing

The company I work for focuses on the core business of manufacturing coating and laminating machinery. A project was started to investigate and eventually develop an AI application for job set-up and production-run supervision.

One of the benefits of the company’s focus on manufacturing machinery in our industry is that the extensive database and know-how that are the primary feeders for AI in industrial applications were available. Before we can even think to use AI in whatever application, in fact, we need to be sure about the availability of the founding bricks of knowledge; the specific package of information extensively used during the day-to-day activities around equipment. The challenge has been to understand if the data used to train operators and converters can be used as well to “train” AI so that AI can support in the selection of process variables during job set-up on a converting machine.

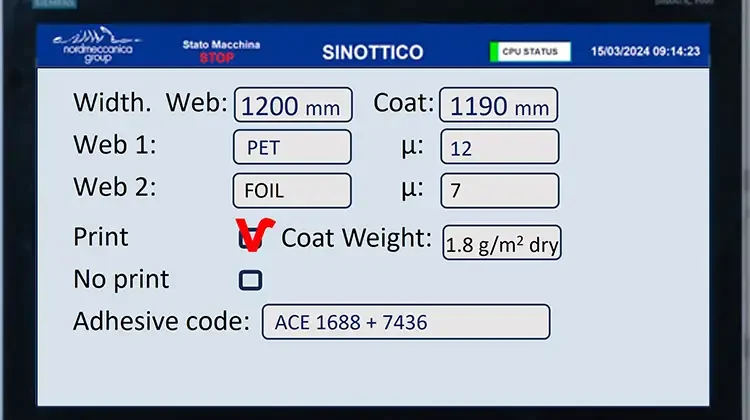

This is not a simple task considering the number of variables involved in the specific field of coating and lamination. These are not just machine-related specifications, but a number of other data influenced by substrates to be converted, the chemistry of the coated compound, target specs of the final converted product, etc. The initial approach has been to schematize the job-analysis phase and the decision-making process that leads to the identification of the proper settings in a conversion process (see Figure 1).

The second stage has been the development of algorithms replicating that same process and powered by AI. These processes, normally handled by an operator, can be brought into the AI environment.

Three steps in machine set-up

In order to explain the evolution of the project, let’s consider the practical case of a two-ply lamination job. Identification of proper machine set-up evolves through three distinct steps:

- Inputs (job description)

- Analysis (decision-making process)

- Outputs (machine settings)

Inputs

Inputs include the two webs to be laminated, chemical structure for the two webs, width and thickness of each, coated width, printed/non-printed, chemical specifications of the coated compound, etc.

Analysis

Given the information provided as Inputs, the experience and know-how of the analyst will identify job parameters (machine settings) for set-up.

Output

Output refers to all of the technical settings for field devices generated as the outcome of the analysis. Just to list a few, these include web tension in each tension-control zone; percentage and profile of the taper tension at the rewind; temperature settings at each temperature-controlled point; air volume and temperature for a dry-bond process involving the drying oven; coating weight; mixing ratios of adhesive compounds (two-component solventless adhesives or three-component solvent-based adhesives); corona treater settings; and anything else that may be involved.

Developing a technology to assist operators during the job set-up stage conveys multiple benefits for the converter. Firstly, it reduces the variable brought in by the human factor. Operators tend to have their personal preferences in machine set-up. Lack of uniformity brings in fluctuations in the quality of the output. Another benefit is the practical effect of supporting operators with little experience in the handling of a production run. This last is a significant benefit. As an OEM, we witness the reality of the fast rotation of operators within the industry, which requires our constant availability to support customers with additional training. No matter how fast and efficient the support provided to the customer, it will never be “real time” and also will carry a cost to the converter. The “experience factor” requires time to be developed, and that is independent from OEM support. A technology that provides machine settings regardless of the operator’s experience supports the converter with increased up-time, higher output, and better and more uniform quality.

Automating the analysis step

In the development of this new technology, the key phase in an AI-assisted job set-up procedure is the automation of the analysis step. The analysis requires data to elaborate; data that currently are patrimony of human experience, memory and know-how. This is the database.

Database

This is the gathering of knowledge, recipes and experiences collected by a converter. It is stored in databases (the archive of recipes) and human minds. It is the human side that tends to stay with the specific person, supervisor or operator. No matter how willing a person is to share his knowledge within an organization, some of his knowledge will remain with him at the time of resignation or retirement. AI primarily works using data analysis and self-learning (machine learning), so one of the most important targets of this process is to make such information the possession of the converter.

Data analysis

Analysis is based on the use of the initial archive of recipes owned by the converter, continuously updated with machine use. The same data is used by human operators.

Self-learning

As new or back-to-back jobs are running, AI accumulates knowledge, and this knowledge is used to improve the database as well as to correct knowledge. This is the real, powerful functionality of AI – AI can learn, which is the part of the decision-making process usually played by the human-experience factor. AI will accumulate knowledge with use, and that knowledge will remain as property of the converter. In fact, it’s not only the initially memorized data that are used by AI; all data that are recorded during the process becomes knowledge for the AI system.

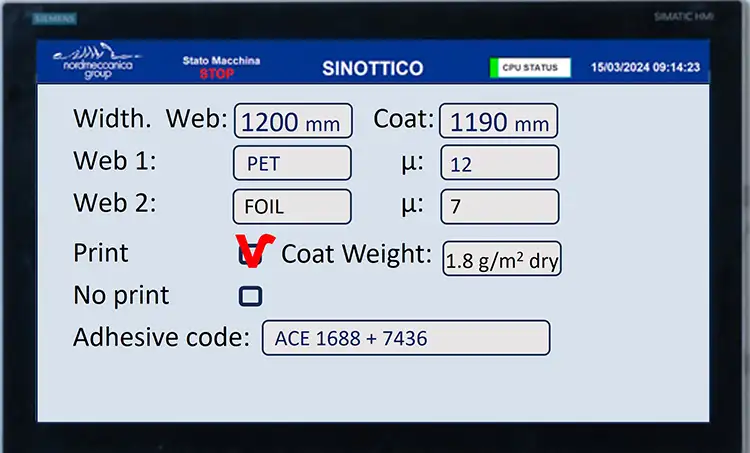

During a job set-up procedure, the Input data are univocally identified. This is the description of the production order. Those data are inputted into the system, with data entry operated through a touchscreen monitor on-board the machine to be set up or remotely (see Figure 2).

The data analysis step is the one that requires the use of a set of information to support the decision-making process. Information could include machine specifications; mechanical and chemical data of the substrates to be converted (type of substrate, width, thickness); data about the chemical compounds to be coated (TDS of the product); personal experience of the analyzer; and the database of previously completed jobs (archive of recipes). This preliminary analysis step follows the same footsteps if performed by AI.

Substrates

The list of substrates to be converted in a coating/lamination process is pretty much standard within the industry. Data includes technical specs and additional information related to products provided by a given supplier. This is information that easily may be codified to be used in every job that involves a specific substrate recorded within the database.

Chemical compounds to be coated

Here, the specs are those listed in the TDS of specific compounds. Once an adhesive or coating is memorized within the database, then the specific set of information can be recalled for every need.

Experience/know-how

The last factor to be considered is the added value brought in by the human part of the equation. Data consist in the accumulation of knowledge and information and the ability to use is as needed. Here, AI expresses the best value. The size of the memory used by the system virtually is unlimited and will contain all initial recipes provided by the converter at system start-up, all the recorded recipes developed during the use of the AI-assisted system and all the knowledge accumulated by the system during every production run performed under the assistance of AI. The last item on the list – self-learning or machine learning – is the most powerful function provided by AI. As new jobs are converted, AI keeps accumulating information and learns through the accumulation of that information. The accumulated knowledge is used in the generation of machine data sets, improving in accuracy as time goes by and new jobs are converted.

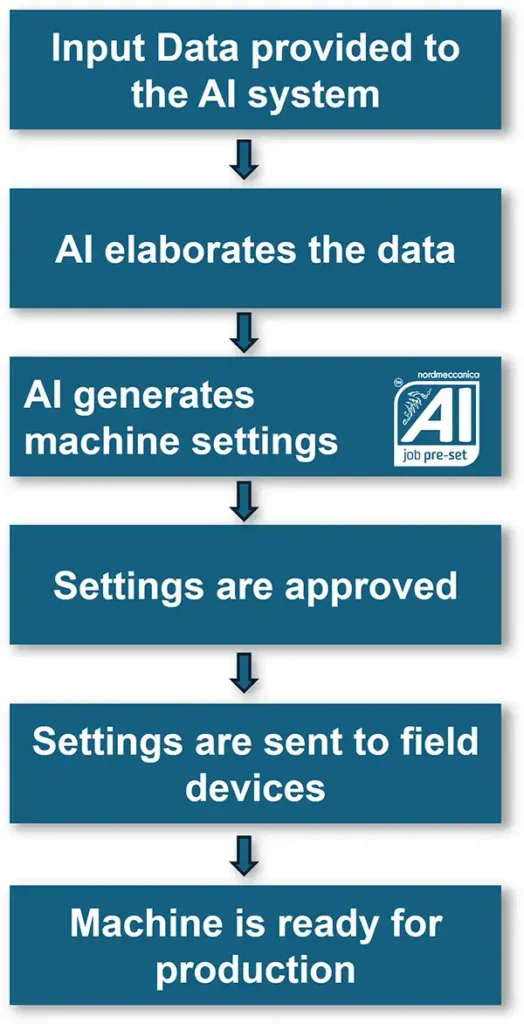

Let’s look at how an AI-assisted job-set up (see Figure 3) unfolds:

- The production department is provided with the production order, which includes the description of the final converted compound.

- Input data is fed into the AI job pre-set system.

- AI elaborates the data.

- AI provides the list of machine settings to be used during the conversion run.

- Settings automatically are sent, after operator/supervisor approval, to the machine field devices through a full pre-setting.

- Machine is ready to run.

The technology can be used over multiple machines of different models and ages. The OEM has developed a calibration of the system targeted to allow settings used on a given model of a given age to be customized to serve different models of different ages (obviously, within reasonable limits of age). For the converter that owns multiple machines (even located in different plants), this functionality offers the ability to use the knowledge developed on a specific unit within the organization on any other machine by the same OEM and performing similar conversions.

Conclusion

The advantages provided by the new technology, as discussed earlier, are significant for the converter and cover aspects such as uniformity of machine settings (even spread throughout multiple machines within the organization), simplification of operator training, containment of the influence of human errors and improvement of machine up-time.

Once the AI-assisted job set-up is completed, with additional optional monitoring and governing (for example, in coating weight or with defect-detection devices connected to AI), the reliability of the system is improved. It may not yet be to “full automatism,” but it definitely moves in the direction of levels of reliability never experienced before in the converting industry.

Giancarlo Caimmi, commercial dir. for Nordmeccanica USA Group (Hauppauge, NY), holds a Ph.D., in Mechanical Engineering from University Federico Secondo (Italy). He has almost 40 years of experience in the converting-machinery manufacturing field. Giancarlo can be reached at 631-242-9898, email: [email protected], www.nordmeccanica.com.