By John Palazzolo, director, Marketing & Sales, Adphos North America, Inc.

Drying and curing are indispensable processes in industrial printing and coating to ensure product quality, durability and production efficiency while minimizing waste and costs. This article explores the definitions, technologies, goals and best practices that drive these essential processes and the benefits that can be achieved by implementing them.

Introduction

Drying involves the removal of liquid from a substrate, rendering it relatively free of moisture. Curing, on the other hand, facilitates a chemical or molecular change via thermal, chemical or UV/EB (ultraviolet / electron beam) molecular crosslinking – to solidify the ink/fluid onto the substrate. Common methods include thermal (via convection, conduction or radiation) and UV/EB technologies, each of which has multiple technologies and application methods.

Technologies for drying and curing

For the sake of this article, we are going to focus on thermal drying and curing.

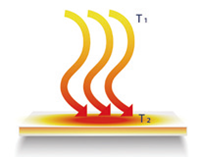

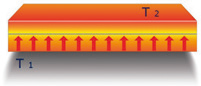

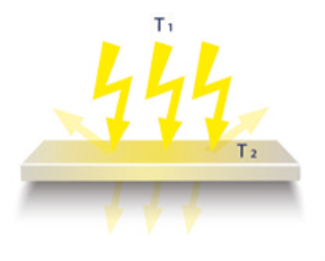

Depending on the type of heat input (convection, conduction or electromagnetic energy), the process is categorized as conventional thermal drying. Various dryer types are derived from these heat input methods:

- Hot air (gas or convection), which transfers heat through gas convection.

- Hot plates or hot rolls (conduction), which rely on direct contact for heat transfer.

- Infrared (medium-wave, short-wave or near-infrared electromagnetic energy), which heats the coated substrate via electromagnetic radiation.

These heat transfer mechanisms are illustrated schematically in Figures 1a, 1b and 1c.

Historically, gas-fired convection dryers have dominated industrial drying tasks due to their advantages. Gas, being an inexpensive fuel, allowed efficient energy input (hot air), facilitated simultaneous steam discharge with hot air and offered straightforward dryer control via adjustments to hot air flow and temperature.

While conduction-based and IR-based electrothermal drying systems presented advantages such as efficiency, compact design and dynamic control, they failed to surpass the dominance of gas-fired convection dryers. This largely was due to the significant cost disparity between gas and electricity (electricity being at least four times more expensive per kWh), the relatively low impact of dryer energy consumption on overall production costs (typically less than 10%) and the heightened fire risks associated with IR-based dryers.

However, this landscape now has shifted dramatically, altering the traditional cost and risk considerations of industrial drying systems.

The solidification of wet layers, such as drying or dehumidification, occurs differently depending on the method used. aNIR (advanced Near Infrared) technology employs photonic energy sources with high power density, combined with integrated airflow to aid in the drying process and remove the moisture (water) from the processing area moisture. This unique combination of energy transfer and controlled airflow allows for efficient drying of the inks and coatings without significantly heating the substrate. Special high-power NIR energy sources are used to:

- Electromagnetically excite (heat) polar molecules (e.g., water or solvents) in the wet film.

- Enable spectral absorption by the solids in the inks/coatings, generating localized heat.

- Minimize substrate heating, leveraging the substrate’s higher mass compared to the ink/coating mass and its spectral absorption properties.

The defined and controlled air mass flow ensures immediate removal of generated vapor at the point of origin, maintaining process efficiency.

Advantages and advancements of aNIR technology

aNIR technology facilitates the adjustment of process parameters during the drying process, including power and power density, temperature control, and input and output air volume flows.

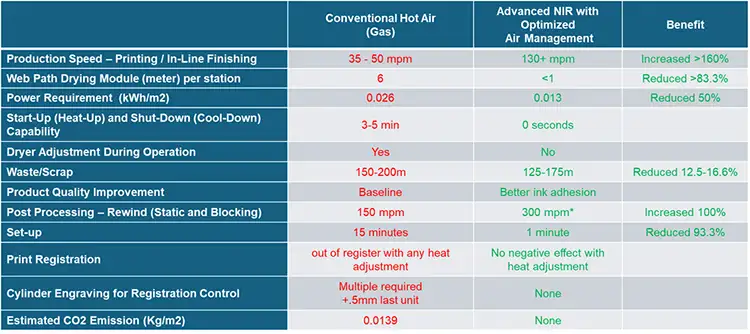

This flexibility allows for precise control of drying processes, enabling quick adaptation to operational or production requirements, often with partial automation. Compared to conventional drying systems, aNIR technology delivers significant advantages in terms of performance, quality and cost-efficiency.

Further innovations in photonic energy sources, including performance, emission spectrum and service life, have focused on:

- Defined temperature control

- Localized mass flow adjustments

- Automated process parameter optimization

- Enhanced drying units and infrastructure requirements

These developments have expanded the application potential of aNIR technologies, making them suitable for high wet layer thicknesses (up to 1 mm) and coatings on temperature- and strength-sensitive substrates, such as flexible packaging.

Considerations for technology selection

There is variability in what “dry” means. To an inkjet press manufacturer, it is achieving 2% less humidity than the substrate’s pre-print condition. To a European book printer, “dry” is determined by the finishing process requirements.

Thus, defining objectives is key when implementing these processes. Key considerations for technology selection include:

- Revenue impact and cost/ROI

- Speed and scrap reduction

- Energy efficiency and sustainability

- Equipment footprint and cost

- Factors to define goals and objectives

The cornerstone of successful drying/curing lies in setting measurable goals. These goals depend on applications (from digital to conventional printing); substrates, which include porous (e.g., paper) or non-porous (e.g., plastic films); and fluid chemistries and application methods, which dictate the drying approach. In addition, post-processing needs should be considered, as in-plant or end-user requirements shape the desired outcomes.

Best practices for optimal results

Achieving optimal drying and curing results requires strategic practices:

- Ensure proper airflow: Align drying capacity with press speed

- Pre-heat or booster units: Prepares substrates for quicker drying

- Real-time monitoring and adjustment: Dynamically optimize ink/coating and dryer settings

- Leverage efficient technologies: For instance, aNIR offers lower energy consumption, minimal waste and better substrate preservation, reducing thermal stress.

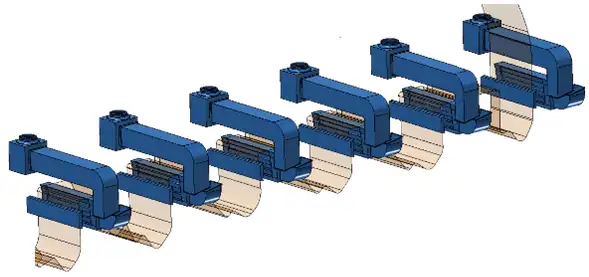

Case studies, such as in gravure printing, show the effectiveness of these strategies, resulting in enhanced print quality, reduced waste and energy costs, and faster turnaround times with consistent substrate integrity. Table 1 shows real-world data from Interprint USA comparing a gas-fired drying system (see Figure 2) to an aNIR-based drying system on a gravure press (see Figure 3).

to an aNIR-based drying system

Conclusion

By clearly defining drying and curing objectives and adopting best practices, manufacturers can optimize their processes. Advanced technologies like aNIR enable industries to achieve greater efficiency, sustainability and product quality. Continuous monitoring and adaptability remain pivotal in aligning drying and curing with production demands.

John Palazzolo joined Adphos North America as director of Marketing and Sales in June of 2006 and has more than 25 years experience in B2B marketing and sales within the digital and conventional printing industries. His customer-focused vision has resulted in the successful development and launch of many new products and product lines. John is a regular speaker at various trade conferences and has written or contributed to articles in a wide variety of trade publications. Palazzolo can be reached at 513-277-0464 or email: [email protected].