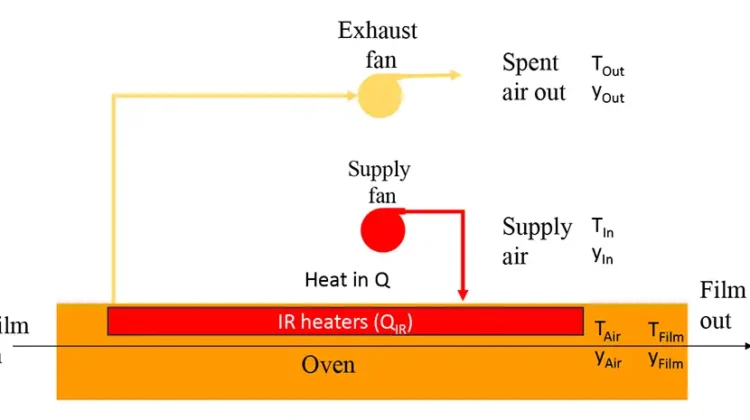

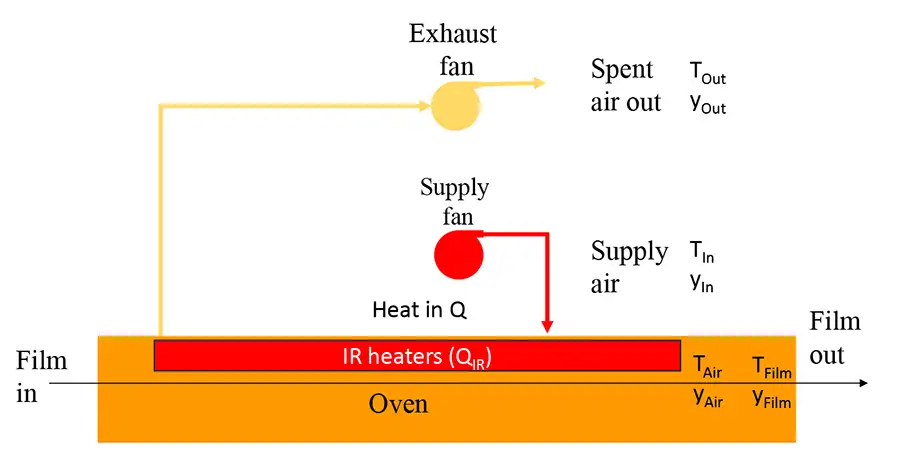

Drying is the removal of a liquid by evaporation. To offset evaporative cooling, drying requires supplying heat to the coating. But there also must be someplace for the vaporized liquid to go; in most cases, that means blowing air into the dryer box [1]. People talk about the heat needed for drying, not the air flow needed. This particularly is common with “do-it-yourself” dryers assembled from commercial heating lamps and supply or exhaust fans that do not blow air directly on the wet coating. For aqueous systems, these are inefficient; for solvent-based systems, they can create large, hazardous clouds of explosible vapor. Consider the simple dryer shown in Figure 1.

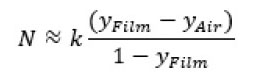

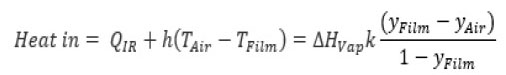

Drying models get complicated, but a simplified heat and mass balance can be useful. The total heat supplied, Q, is the sum of the heat supplied by the IR heaters and convection. At steady state, this has to balance the evaporative cooling (i.e., the evaporation rate times the enthalpy of vaporization of the solvent). A simple model for the evaporation rate (in moles per unit area), N, is given in Equation 1 [2].

This defines the mass transfer coefficient, k. The corresponding heat balance (see Equation 2) defines the heat transfer coefficient h. TFilm and yFilm are the surface temperature of the coating and the mole fraction solvent in air at the surface. TAir and yAir are the temperature and mole fraction solvent near, but not right at the surface of, the film.

If the supply air is blown onto the film through nozzles, TAir = Tin and yAir = yin. If the supply air is heated, TAir is high and yAir is low. If the air is just added to the box, TAir and yAir are close to the exit temperature and concentration TAir is low and yAir is high; both heating and evaporation rates are minimized. If the supply air is not heated, convection is cooling, not heating, the film, and it is not as obvious that nozzles help. But, the more IR heating and the less heating from convection, the hotter the film will be at the same drying rate. Some products develop better properties if the coating is dried hot; other products develop better properties if the coating is dried cold. There is no way to divine the optimum ratio of IR vs. convective heating. But there usually is an optimum ratio of convection vs. IR. Table 1 gives typical ranges for different IR sources.

![TABLE 1. Typical breakdown of IR vs. convective heating for products that dry better with IR [3]](https://convertingquarterly.com/wp-content/uploads/2025/02/cq125coatingconcepts_table1.jpg)

Conclusions

Drying requires heating but also a way to remove evaporated solvents. Some products benefit from drying at low temperature; other products benefit from drying at high temperature. But all products benefit from having an optimal mix of pure heating and drying. And all operations benefit from engineers being intentional about how heat is supplied and solvent is removed from the oven.

References

- Some specialty dryers use chilled condensing plates to remove the solvent from the box. See US Patent 9,958,202, “Inerted plate dryer and method of drying solvent-based coating,” J. De Santos Avila, K. N. Christodoulou, A. Khodaei, A R. Mehrabi, L. Sartor, H. De Koning, G. Arkesteijn, for a review.

- See R. B. Bird, W. E. Stewart, E. N. Lightfoot Jr., Transport Phenomena, John Wiley and Sons, Inc., New York (1960). https://doi.org/10.1002/aic.690070245, Example 21.2.2. Drying proceeds by at least three stages: heat up, constant rate and falling rate. This model applies to the constant rate stage.

- Data in this chart from D. Satas Web Processing and Converting Technology Equipment (1984), Van Nostrand Reinhold Co,. except fluid panels and VCSELs. I have not found data on VCSELs.

E.J. (Ted) Lightfoot, Ph.D.

716-449-4455; ejl@tedlightfoot.com

ARC Member; ARC TV Presenter;

ARC R2R Presenter