By Alison Keane, Esq., CAE, IOM, president and CEO, Flexible Packaging Assn. (FPA)

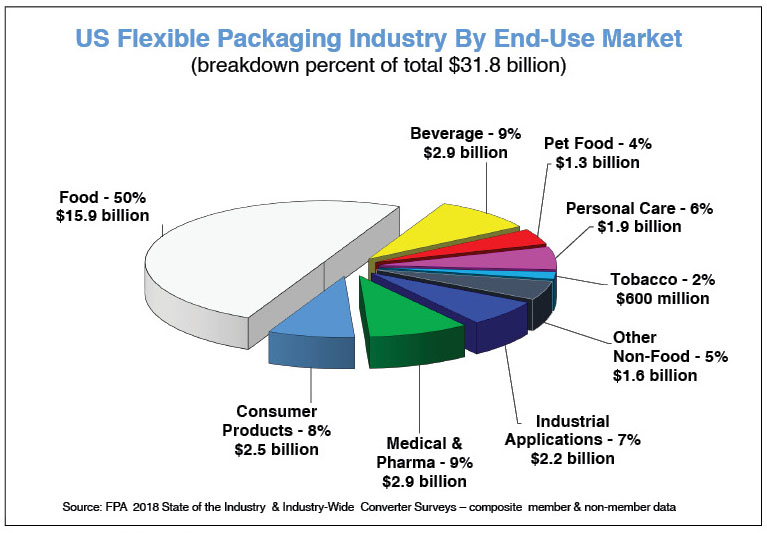

The last several years have shown a slow but steady anti-plastic sentiment, and, in 2019 in the US, we saw several legislative initiatives that purported to curb “single-use” plastic waste. But, not all plastic is created equal, and legislation introduced around plastic waste actually includes all packaging types, regardless of material. In the meantime, the flexible-packaging industry is projected to grow in every category, including in every segment of its largest category – food (see Figure 1). So, how is FPA addressing two seemingly opposing outlooks for 2020 and beyond?

FPA believes it means that even with the challenges of plastic pollution and marine debris, the industry is well positioned to continue to grow in the US because of – and not in spite of – its environmental sustainability. At the same time, end-of-life management of flexible packaging must be solved, both in terms of packaging design and recovery infrastructure, to address consumer demands and consumer product groups’ and retailers’ published sustainability goals.

A $31.8 billion force for good

Flexible packaging currently is the fastest-growing segment of the packaging industry – at 19% – just behind corrugated containers at 22%. Flexible packaging is defined as any package or part of a package whose shape can be readily changed. It includes packaging made with paper, plastic, film, foil, metallized or coated paper and film, or a combination of any of these materials. The flex-pack field is a $31.8-billion industry, employing 79,000 people in the US across approximately 950 manufacturing facilities.

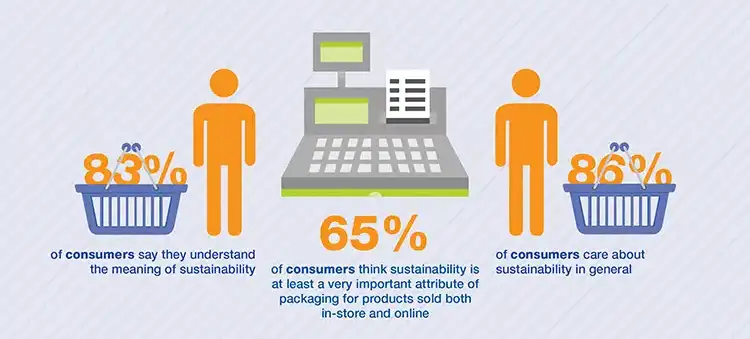

A recent FPA survey of consumer and brand-owner perceptions of the sustainability of packaging revealed that 86% of consumers care about sustainability in general; 83% say they understand the meaning of sustainability; and 65% think sustainability is at least a very important attribute of packaging for products sold in-store and online. Further, 82% of consumers say they care about the sustainability aspects of packaging; 79% say they prefer products that are in sustainable packaging over ones that are not; and 72% say they trust labels that include sustainability benefits on product packaging. So sustainable packaging matters to consumers (see Figure 2).

The survey also found that younger generations are more likely to understand and define sustainable packaging as considering all lifecycle benefits, rather than simply end-of-life benefits, such as recyclability. In fact, millennials said it’s extremely important or absolutely essential that product packaging has a sustainable lifecycle, including that it is manufactured with less energy and has been transported efficiently. Flexible packaging, including flexible plastic, goes even further with reductions in water use, greenhouse-gas emissions, product-to-package ratios and materials to landfills.

Case-study comparisons

So, FPA developed case studies to show the difference between flexible packaging and traditional packaging when it comes to environmental benefits, particularly when speaking to brand owners looking to transition their packaging (www.flexpack.org/sustainable-packaging/lca-case-studies/). We also launched a new Website, www.perfectpackaging.org, to tell the sustainability story in ways a consumer or policymaker could more easily understand the science behind flexible-packaging innovations and why so many consumer products companies (CPCs) have transitioned to it. And, we started a platform for conversations on social media, particularly with younger consumers, on Twitter, Facebook, Instagram and LinkedIn. New case studies on ecommerce packaging will be released this year, and an influencer program will be undertaken to push the message out further.

In one case study, where the difference between plastics easily was seen, FPA detailed the difference from an environmental-lifecycle standpoint of flexible standup pouches for laundry detergent pods vs. rigid PET containers. The use of single-dose pods has become a popular method for packaging laundry detergent, replacing liquid or powdered detergent with pre-measured dissolvable packets. When it came to the lifecycle aspects of water use, greenhouse-gas emissions and fossil-fuel consumption, the standup pouch won hands down. In fact, even when considering current US recycling rates for PET, which is readily recyclable, the rigid PET container results in nearly 4X more material ending up in the landfill than the flexible pouch (assuming zero recycling for the pouch).

Legislative, regulatory advocacy & action

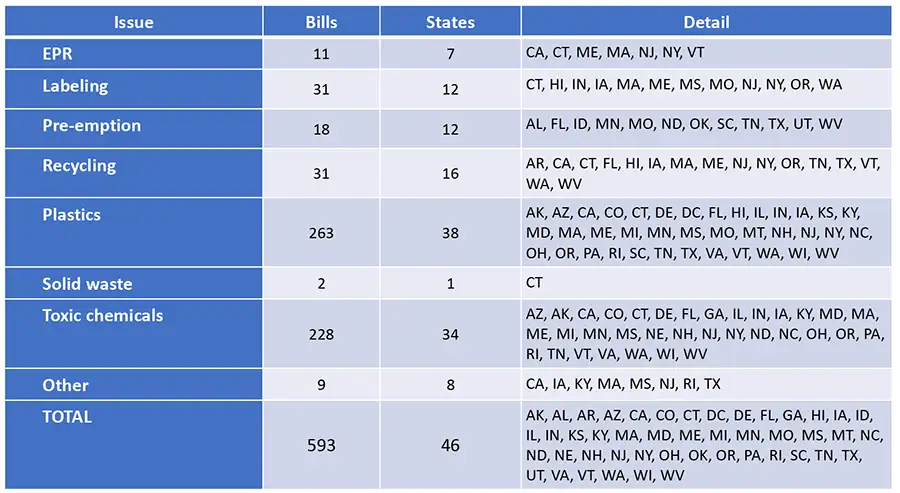

Our work does not stop with outreach and education on flexible-packaging sustainability aspects, however, as end-of-life management of flexible packaging is of upmost importance given current CPC and retailer sustainability goals, as well as the demand from consumers and legislators regarding recovery and recycling of packaging. As stated earlier, 2019 showed the most significant amount of attention to date in the US around packaging, particularly plastic packaging and single-use plastics, with bills in four states and a concept outline at the federal level; and while none of the bills were passed last year, all will be back in 2020 (see Table 1).

To better advocate on behalf of the industry, FPA established key advocacy points and used them at both the federal and state levels to steer the conversation and suggest improvements to legislation, thus providing real solutions. Under FPA’s policies, any packaging legislation 1) must address infrastructure needs first; 2) should look at the entire lifecycle of the packaging and not just its recyclability or compostability; 3) should treat waste-to-energy (WTE) as a viable option, at least while more advanced technologies are brought to scale for packaging waste; 4) should use funding for new infrastructure and not just reimbursement for current recycling; and 5) must involve the consumer, to bring about meaningful change.

A key development in 2019 was the progress made with a bill introduced on recycling infrastructure, titled “Realizing the Economic Opportunities and Value of Expanding Recycling Act (RECOVER Act).” As part of a broad coalition that worked to draft and get the RECOVER Act introduced, FPA supports the Act as we believe a suite of options is needed to address the lack of infrastructure for flexible-packaging materials in the US. Investment in that infrastructure is necessary before new mandates and unrealistic goals are set for both producers and consumers and before short-sighted bans are imposed. Current infrastructure is not adequate to process even the readily recyclable packaging that is being produced, let alone the flexible packaging that has emerged over the last two decades. The RECOVER Act will address the need to expand domestic recycling infrastructure and create end-markets, diminishing the need for Extended Producer Responsibly (EPR) legislation at the federal or state level.

Movements on the state level

At the state level, 2019 started with an ambitious EPR bill for packaging in Washington State, followed by a report in Rhode Island by the Governor’s Task Force to “Tackle Plastics” and a bill in California for specific rates of municipal solid-waste reduction, recycling and composting by specific dates, which producers would have to meet to continue selling their products and packaging in the state.

The California bill (Senate Bill 54/Assembly Bill 1080) went farther than any plastic and packaging legislation last year and any programs to date in Europe or Canada. Finally, in Maine, the legislature passed a resolution to study EPR for packaging, which resulted in a conceptual model for a packaging EPR system designed to be introduced in 2020.

As FPA continues to believe that there will not be just one solution to packaging-waste issues, we continue to pursue multiple programs/platforms that will help our members in the debate. Two of our continued infrastructure projects, the Materials Recovery for the Future (MRFF) (www.materialsrecoveryforthefuture.com/) and the Hefty® EnergyBag® Program (www.hefty.com/hefty-energybag/hefty-energybag-program), are ongoing, as well as a new partnership with the University of Florida and its Advanced Recycling Center. All seek to solve the lack of recycling infrastructure and end-markets for flexible-packaging waste.

Two others, Californians for Recycling and the Environment (CRE) and a dialogue facilitated by the Product Stewardship Institute (PSI), are specific to packaging legislation and lobbying on behalf of FPA polices. CRE is a grassroots effort in California, which ran parallel with the legislation, but unlike our traditional lobbying efforts (working with the sponsors and staff on the legislation itself), CRE was focused on consumer education and outreach. PSI represents state and local government agencies, dealing with solid-waste issues, and it attempts to find consensus-based solutions that benefit both sides. Educating government participants on the environmental benefits of flexible packaging and various ongoing projects to provide for its end-of-life is a key component to avoiding product bans.

Conclusion

FPA encourages the entire supply chain to join in the conversation. To keep the outlook for flexibles bright, we need good science, and we need to articulate that science in an easy and meaningful way. Let’s start arming consumers, CPCs, retailers and policymakers with the truth about the environmental benefits of flexible packaging, including plastics. Without this effort, truly sustainable and lifesaving plastic packaging may indeed be sacrificed for less environmentally beneficial alternatives.

More info: www.flexpack.org