By Eldridge M. Mount, Ph.D., president, EMMOUNT Technologies

Abstract

Polymer film labels have been evolving for some time and today are widely used with a wide variety of application methods. Originally developed as a means to replace paper labels for existing and new polymer containers, polymer labels now are finding applications with the potential for recycling improvement with the evolving focus on single polymer packaging. This paper will focus on polymer label face stocks, what makes them desirable and what features must be added to polymer films to make an outstanding label face stock.

Why polymer labels?

Labels are an important industrial commodity because they supply critical information to consumers about what is contained in a protective package. This readily is shown in Figure 1, which contrasts a properly labeled soup can with a can that has lost its identifying label. Without its label, it is anybody’s guess as to what type of soup – or even if it is soup – is in the unlabeled can.

For many decades, the primary substrate for container labels was constructed of paper and was used successfully with a wide range of container products and label-application equipment. In the middle of the 20th Century and especially after WWII, many new polymers were discovered and became commercially available. Subsequently, films produced from these polymers were developed and began to replace cellulose-based products, such as cellophane and paper, in many packaging applications. Ultimately, polymers began to replace traditional materials, such as glass and metal cans, as containers to reduce weight and hence the energy needed to produce and transport glass and metal containers. Consequently, the desire for polymer labels to replace paper labels continued to grow so that, by 1986, US Patent 4,713,273 [1] stated:

“Many label and sign applications require that the face material be a polymeric film material which can provide properties lacking in paper, such as weatherability (for outdoor signs), strength, water resistance, abrasion resistance, gloss and other properties.”

With the introduction of polymer containers of varied and irregular shapes, you also can add conformability of the label material to the list of other properties alluded to in US Patent 4,713,273.

Better recycling, improved printing attributes

While paper may be defined to have many shortcomings, it also has many highly developed attributes, especially in relationship to the graphic arts. Because labels are so important in conveying information to the consumer, polymer-based labels must be, foremost, a high-quality, graphic-art substrate. However, as the use of polymer containers grew, the incompatibility of paper labels with recycling containers also became more apparent, and both of these needs are described in 1994 in US Patent 5,288,548 [2]:

“One shortcoming in general with the use of polymeric films with label stock is that they may not have excellent printability with high-speed, dot-matrix and thermal-transfer printers. Thermoplastic label stock is also much desired in contrast to paper labels from the standpoint of recyclability. Paper labels intermixed with recyclable plastic film present a significant problem since the two materials are not easily separable. Thus, there is an ever-increasing need for plastic film label stock as opposed to paper labels.”

US Patent 5,288,548 solves the graphic-arts printability problem of plastic films with the use of acrylic polymer coatings applied to the polymeric label face stock film, while US Patent 5,194,324 [3] coextrudes a layer of medium-density polyethylene on an oriented polypropylene film to produce a surface comparable to coated papers. Both approaches create robust graphic-arts printing solutions for polymer label applications.

Application attributes

![FIGURE 2. Figure 3D of US Patent 4,713,2731 [1] demonstrates the release of a pressure-sensitive label [34] from a release sheet [10]. The stiffness of the label prevents the label [34] from following the release sheet [10] as it turns over the peel back edge [38] of the applicator to contact the pressure-sensitive adhesive [39] to the product [36] allowing the application of the label.](https://convertingquarterly.com/wp-content/uploads/2025/02/cq320rll-mount-Fig2.webp)

Automated, high-volume label-application methods are many and varied from pressure-sensitive, roll-fed, cut-and-stack, roll-on/shrink-on, etc., and most have the need for an adhesive and film properties that are compatible with the application method and the container the label is adhered to. For efficient application to products, one primary attribute of the label is a certain level of stiffness and conformability. This is especially true for the application of die-cut, roll-fed, pressure-sensitive labels, as shown in Figure 2.

Label stiffness is important in most label-application methods to permit the transfer of the label from its carrier or adhesive application to the final product for application. While the label must be stiff, it also must be conformable to the shape of the container, especially if it has an irregular or curved shape. This can be a strong advantage of polymer labels in comparison to paper labels.

Polymer labels generally are impervious or little affected by moisture in comparison to paper labels, and therefore improve the durability of labeled products. At times, it is advantageous to produce laminated labels to further enhance the appearance and resistance of the label’s printed information to scuffing or abrasion during handling or distribution.

How to build a polymeric label

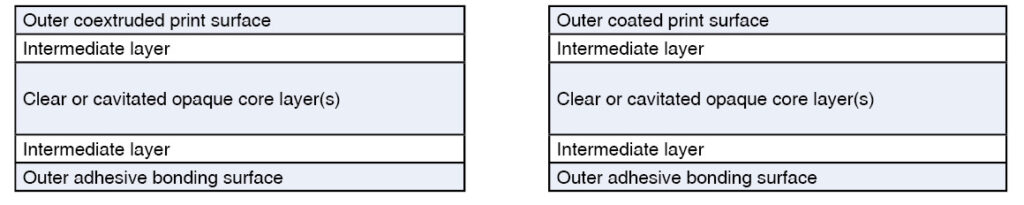

To produce a polymeric label with the many attributes needed and to permit a high-quality, graphic-arts surface for printing on one side and the need for excellent adhesive bonding on the opposite side, coextrusion of a multilayer polymer film is employed (see Figure 3). Claim 19 of US Patent 4,713,273 summarizes fairly well what a polymeric label represents:

“19. A multilayer facestock for use in pressure-sensitive label, tape or sign applications comprising a coextrudate of cojoined layers comprising a relatively thick core or base layer of polymeric film material of a stiffness of between 10 and 100 Gurley and which contributes the majority of the dimensional stability and stiffness of labels or signs cut or formed from the facestock, and at least one relatively thin skin layer, said skin layer being on the face side of the coextrudate and having an ink-printable surface, and a pressure-sensitive adhesive layer combined at the side of said coextrudate opposite said face side.”

While cast-coextruded films might be adequate for labels in some instances, the strength, stiffness and conformability generally required of the label substrate generally is improved by the use of mono- [1] or biaxially-oriented [2,3] films. Orientation of the coextruded film significantly improves the overall balance of mechanical properties and stiffness to produce a superior product, which can effectively compete with and replace existing paper labels.

Clear or opaque coextruded oriented label substrates also may be produced. Opaque films are oftentimes produced by the internal cavitation of the substrate during the mono or biaxial orientation of the polymeric film [1,2]. Cavitated films generally are white, due to internal voids producing internal light scattering [4], and therefore have a generally paper-like appearance. At times, white pigmentation is added to the design of the cavitated films and used to control the visual aspect of the cavitated film, in terms of gloss or matte appearance or to meet specific spectral requirements of specific customers.

Heat-shrinkable labels

Mono- and biaxially-oriented films permit the potential for some tailored heat shrinkage of the label to allow complete container coverage, with improved conformability, to complex-shaped containers, such as blow-molded or stretch-oriented containers (see Figure 4). This heat-shrinkable behavior is not possible with paper labeling and has many advantages for specific applications.

Such heat-shrinkable labels do not require large quantities of preprinted containers, reducing inventories, and permit the production of just enough product, thus reducing container waste. Such labels also may provide for use of thermal bonding to produce a heat-shrinkable sleeve, thereby eliminating the need for adhesive application of the label, which then can be more easily separated from the container for recycling.

Polymer selection

Label stiffness is built into the label substrate by polymer selection, overall thickness of the face stock and cavitation of the substrate. In general, label substrates are produced from oriented polypropylene (OPP), oriented polyethylene (OPE), oriented polyester (OPET) and oriented polystyrene (OPS), to name a few. Initially, label substrates were used with many types of polymer, glass and metal containers and generally improved recycling of glass and polymer containers by eliminating the need for container printing. This was important especially for glass containers because mineral pigments in some glass-container inks limited glass recycling due to a molecular breakdown of the glass on remelting (glass is just a silicon-based polymer).

Recycling of mixed polymer labels and containers, such as OPE labels on polyester containers, initially was less important due to the end uses of many recycled-polymer products. However, today, with an increased drive for more effective use of recycled polymers, the use of single base-polymer combinations, such as OPET labels on polyester containers, PE labels on PR containers, etc., is gaining importance. This can be expected to drive the development of new label substrates and may increase the cost of labeling in some instances. The increased cost is due to single-polymer solutions limiting label performance or needing increased label thickness to maintain required properties.

There never will be a perfect single-polymer label/container combination due the need for variations within a polymer family for the container and label; i.e., the polyethylene used for a container is likely a different polyethylene, in copolymer composition, molecular weight and viscosity, from the polyethylene that would be used for the coextruded polyethylene label substrate. This would produce a mixed-polyethylene recycling stream which, while forming a more chemically compatible recycling stream, would have properties likely not usable back into the original container or label production. This generally would be true of all container/label polymer families. The use of graphic-arts coatings to improve label printing and performance as opposed to coextruded print layers on label substrates would be expected to limit the compatibility of a recycled label.

The addition of oxygen- and aroma-barrier properties to produce barrier labels is found in the use of oriented coextrusions containing EVOH and Nylon layers [5] in some specific food-packaging applications.

Conclusion

Polymeric film labels have been evolving over the last 40 or 50 years along with the emergence of more types of polymers and the growing use of polymers in packaging. We must not forget – or overlook – the significant positive impact that polymer packaging combined with polymer labels has had and will continue to have on reducing the total weight and, therefore, cost and energy used to produce, package and transport products from the manufacturers to the final consumer. Polymer labels can improve the recovery and recycling of polymer containers by reducing the use of paper labels and reducing the environmental impact of paper production on air and water quality, relative to that of polymer-film production.

References

1. US Patent 4,713,273, Melvin S. Freedman, Avery International Corp., Dec. 15, 1987

2. US Patent 5,288,548, Ralph J. Weber, Mobil Oil Corp., Feb. 22, 1994

3. US Patent 5,194,324, Robert V. Poirier, Mobil Oil Corp., March 16, 1993

4. US Patent 4,377,616 Ashcraft, et al, Mobil Oil Corp., March 22, 1983

5. US Patent 4,755,419, Gautam P. Shah, W.R. Grace & Co., Cryovac Div., July 5, 1988

Eldridge M. Mount III, president of EMMOUNT Technologies LLC (Canandaigua, NY), has more than 35 years of industrial experience in the extrusion and orientation of polypropylene and polyester films at ExxonMobil Chemical and ICI Americas Film Divs. He holds a Ph.D. in Chemical Engineering from Rensselaer Polytechnic Institute. Mount writes the “Substrate Secrets” Q&A column and moderates the “Substrates” Technical Topics online channel for this publication. He can be reached at 585-223-3996, fax: 585-919-6504, email: emmount@earthlink.net, www.emmount-technologies.com.