By Craig Rappe, field applications engineer-Industrial Coatings at Advanced Energy Industries, Inc.

Thin-film coating professionals struggle with a variety of issues in reactive sputtering. These include the need to reduce process temperature for heat-sensitive substrates; power level limitations due to heat, material and current; and anodes that “disappear” in high deposition-rate configurations. The development of the Dynamic Reverse Pulsing (DRP) power configuration eliminated those challenges by lowering heat and increasing the deposition rate, requiring fewer chambers, and increasing throughput of existing coaters without the expensive addition of cathodes, lids and zones. DRP’s unusual capabilities have transformed the paradigm in reactive sputtering and allowed thin-coat professionals to enable new processes and reap substantial cost savings.

DRP configuration capabilities now have been expanded further to support co-sputtering and co-reactive sputtering. DRP 2.5 uses a magnetron-sputtering configuration but with two or more different target materials to form a single thin-film material with two or more constituent elements in it. No other magnetron-sputtering configuration such as this can be used for co-sputtering or co-reactive sputtering. This configuration creates several significant benefits, including: 1) lower substrate heating, which is important for heat-sensitive substrates (i.e., plastics, including polyethylene terephthalate [PET], the most common thermoplastic, and more); 2) a significantly higher deposition rate than standard bipolar, dual-magnetron sputtering (DMS); and 3) lower arc generation leading to lower particle generation. For web coating of materials such as PET, the lower substrate heating is critical.

Editor’s Note: The following paper won the 2020 AIMCAL John Matteucci Technical Excellence Award for Vacuum Web Coating at the AIMCAL R2R USA Virtual Conference held online in October 2020. More info: www.aimcal.org

The 2020 AIMCAL Matteucci Award for Web Coating was bestowed on “Troubleshooting and defect reduction in coated products” by Dr. E.J. (Ted) Lightfoot, principal consultant at Ted Lightfoot LLC. That paper was published in Converting Quarterly 2020 Q1, pp. 52-54.

Introduction

As thin-film coatings have evolved, consumers and businesses have benefited from revolutionary advances in all aspects of technology. With wide-ranging impacts to semiconductors, flat panel displays, consumer electronics, autonomous vehicles, glass surfaces, manufacturing tools, optical sensors, architectural glass and solar photovoltaics, to name a few, thin-film coating is a major enabler for virtually all aspects of modern life and business.

Despite the continued progress, however, the industry is battling a variety of roadblocks in bringing the next new technological advancements to market. One of the ongoing balancing acts in thin-film coating is achieving higher deposition rates where films or substrates are sensitive to heat loads. This issue spans the industry – from metal parts with plastic inserts to optical and other films where higher thermal loads are not acceptable.

In this ongoing balancing act, a new power configuration innovation was developed recently to directly address the conflicting requirements of deposition rate and thermal loading. Dynamic Reverse Pulsing 2.5™ (patented), referred to as DRP 2.5, is a new power configuration technology that is marked by providing higher deposition rates, lower substrate heating and an option for co- and tri-material sputtering.

Configuration comparison

Traditional DRP was introduced during the 2015 Society of Vacuum Coaters TechCon technical conference [1]. First employed in a large-area coating application, DRP capabilities now are in development across a wide variety of dual-magnetron coating (DMS) applications. By enabling manufacturers to use capital equipment to make more product and money with minimal capital investment, DRP 2.5 is continuing to change the paradigm for many roll-to-roll (R2R) systems.

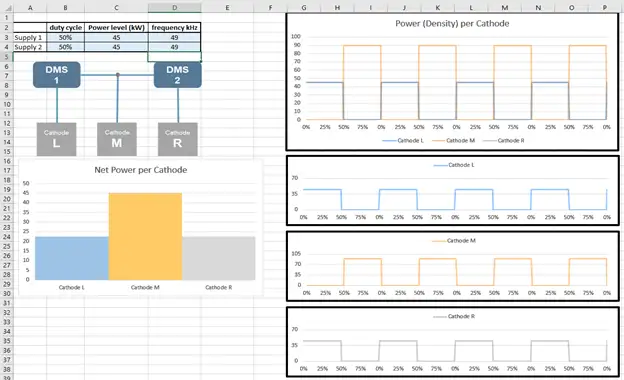

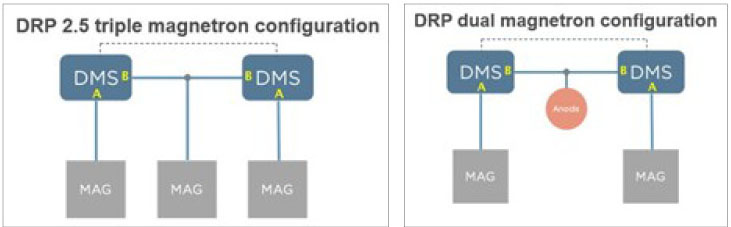

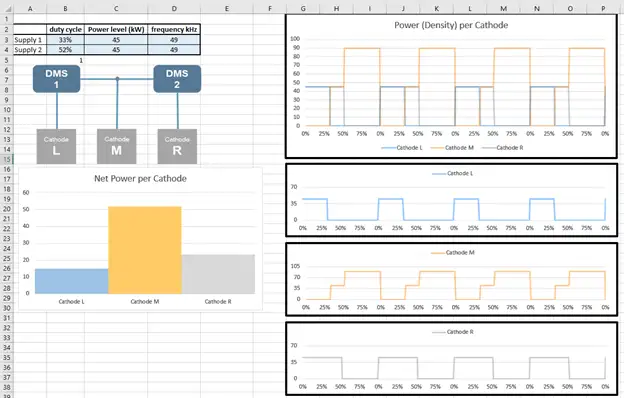

This new power configuration combines the benefits of pulsed-DC sputtering with the benefits of dual-magnetron sputtering, while reducing the maintenance and thermal issues associated with these two types of sputtering. To enable this new capability in triple-magnetron systems, the DRP 2.5 configuration uses two DMS bipolar power supplies and three cathodes (see Figure 1). Synchronizing and controlling the two DMS units as a power system allows power to be delivered to all three magnetrons, effectively using all the delivered power for sputtering while decreasing substrate and system heating. This provides a very high deposition rate and enables sputtering multiple materials to create advanced film properties and reduce the costs associated with traditional alloyed material targets.

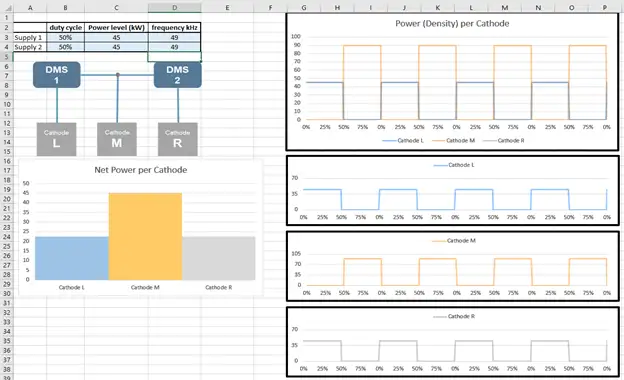

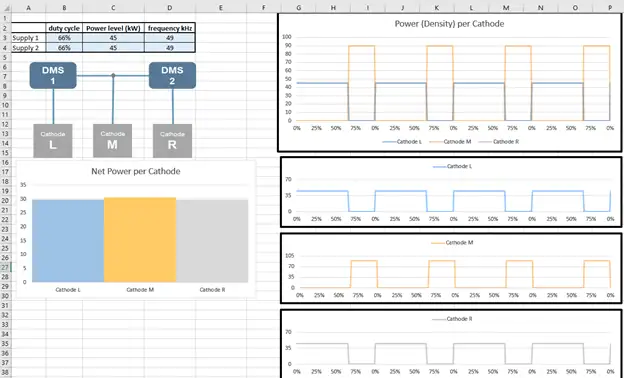

DRP 2.5 replaces the anode(s) in the original DRP configuration with a third cathode. Sputtering is occurring 100% of the time while decreasing the overall heat load in the system and on the substrate. With this new configuration, using one, two or even three different target materials expands the range of layer compositions achievable without changing targets. This also reduces the cost to research different material compositions with the ability to use up to three base materials. In addition, this provides for changes in film properties and layer elements by adjusting the duty cycles and power levels of the power supplies.

Deposition time nearly doubled

Often seen as surprising, DRP improves the “working” utilization of cathodes in a dual-magnetron system [4]. DRP’s unusual power configuration increases the deposition time of cathodes in a DMS up from the classic 50% to 85% to 90% (DRP). DRP 2.5 expands on DRP by adding a third magnetron, enabling even more efficient use of delivered power to deposit film and similar benefits in heat reduction.

The benefits of co- and tri-sputtering can be visualized in the following power-density models (see Figures 2-4).

In one of the initial R2R coater implementations of DRP 2.5, two different materials were used in the layer. Total system power was increased by 45%, the temperature in the system decreased and the web speed increased by 20%. The composition of the layer was adjusted by power levels and duty cycle within each DMS. The problematic anodes were no longer needed, uptime increased and tool maintenance reduced.

Conclusion

The application of the DRP 2.5 power configuration continues to evolve, including implementations in novel triple-cathode and single-cathode sputtering. This power configuration enables increased deposition rates, lower substrate and system temperatures, reduced coater maintenance and more flexible material composition. Additional publications of process advancement that included the original DRP power configuration include a paper from 3M Co. at the 2016 SVC TechCon[2] and a Vergason Technology publication in the SVC Fall/Winter 2017 Bulletin [3].

References

- Douglas Pelleymounter, “Raising the Bar on Reactive Deposition Sputter Rates,” Advanced Energy, SVC TechCon 2015 presentation.

- Chris Merton, Scott Jones, “Dual Magnetron Sputtering of Aluminum Oxide: Experience with an Alternative Approach,” 3M Corporate Research Lab, SVC Paper #W-8, SVC TechCon 2016 presentation.

- Michael Brazil, “Developing a Reactive Magnetron Sputtered ZrCN Decorative Coating for Plastic Substrates,” Vergason Technology, Inc., SVC Fall/Winter 2017 Bulletin.

- Dave McAninch, “Eliminating thin-film coating roadblocks with power configuration innovation,” Advanced Energy, Converting Quarterly 2018 Q4, pp. 66-69.

Craig Rappe, field applications engineer-Industrial Coatings at Advanced Energy Industries, Inc. (Denver, CO), has been in the physical vapor deposition (PVD) industry since 1988 and has served in various roles. He spent 18 years as an end-user of three large-area, architectural glass coaters and more than nine years selling and supporting rotary cathodes in numerous markets, including roll-to-roll (R2R), display, solar, glass and decorative. In his current position, Craig focuses on providing advanced power solutions to application and process challenges as well as educating the next generation on “electron management” as often as possible. He can be reached at 507-456-3965, fax: 970-407-5102, email: craig.rappe@aei.com or www.advancedenergy.com.