By Butch Schomber, global business development mgr., and Paul Young, narrow-web account mgr., Maxcess RotoMetrics

Label converters continue to see a trend toward thinner liners and face materials. Thinner materials have several advantages in the market, including reducing waste, increasing yields, cutting costs, boosting aesthetics as well as label-dispensing benefits. While significant advantages exist, thin film conversion is not without its challenges. Thinner films require tighter die tolerances, complementary press components working better together (tension, rolls, guiding technologies, unwind and rewind) and temperature control. Working closely with your rotary die supplier can help to identify potential challenge areas and provide valuable solutions to optimize press performance.

Introduction

Critical diecutting and converting are no longer just about the die station. All web components must function better together and be in good working order to successfully convert today’s more challenging substrates’ requirements. Converters today must keep up with new technologies, increased automation, faster turnaround times and many other variables.

Over the past few years, not only have the largest brands converted to thinner substrates to reduce waste and save money, many middle market brands and smaller private-label products have moved to thinner liners and face materials (see Figure 1). The push for thinner liners and facings revolves around the significant advantages they provide:

- Sustainability – less landfill waste

- Increased yields – more labels per roll

- Material costs – less material equates to fewer dollars spent

- Increased shelf appeal – the “no-label” look

- Dispensing advantages – fewer roll changes on the label applicator

Given this trend, converters must adapt to ensure their equipment is working better, faster and smarter to maximize both the printing-press and converting-line performance.

Defining “thin” materials in label converting

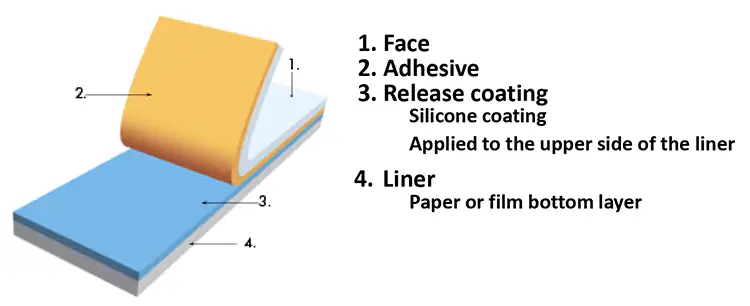

So, what is “thin” when it comes to today’s and tomorrow’s liners and face stocks? Simply put, it is a reduction in material caliper for the pressure-sensitive label stock and/or silicone-coated release liner. Over time, the trend has been toward going thinner and thinner for both substrates.

Some label stock examples:

- BOPP: 2-mil > 1.6-mil > 1.2-mil > 1-mil as the current standard

- PE: 3.8-mil > 3.4-mil > 3.0-mil > 2.2-mil (possibly going even thinner)

- MDO: 3.5-mil > 2.5-mil > 2-mil (possibly even thinner)

- PET: less than 1-mil (trend toward thinner continues)

Some release liner examples:

- 1.2-mil PET is being replaced by thinner liners

- 0.92-mil / 23-micron PET (commonly used today)

- 0.75-mil / 19-micron PET (now used in many high-volume applications and expanding)

- 0.48-mil / 12-micron PET (becoming commonplace)

- 0.0024-in. SCK paper liners

- 0.0016-in. high-impact glassine

The trend toward “thin” also may include the adhesive coating on the label face stock. Different adhesive formulations are allowing thinner coatweights with the same or better performance.

All elements working better together

Thin materials are here and only getting thinner, so all web components must work better together to ensure success.

As a result, inspection and auditing of all press components are extremely important. From end-to-end, unwind to rewind, material guiding, web tension and finishing – all must work together to maximize machine yield. Nip and idler rolls, inspection devices, controllers, load cells, tension amplifiers, pressure-measuring systems, brakes and clutches, and rotary tooling must complement each other all along the web to minimize downtime running challenging thin films. While all these components and parts are important, die-station condition is critical to ensure proper die strike on thin-film materials.

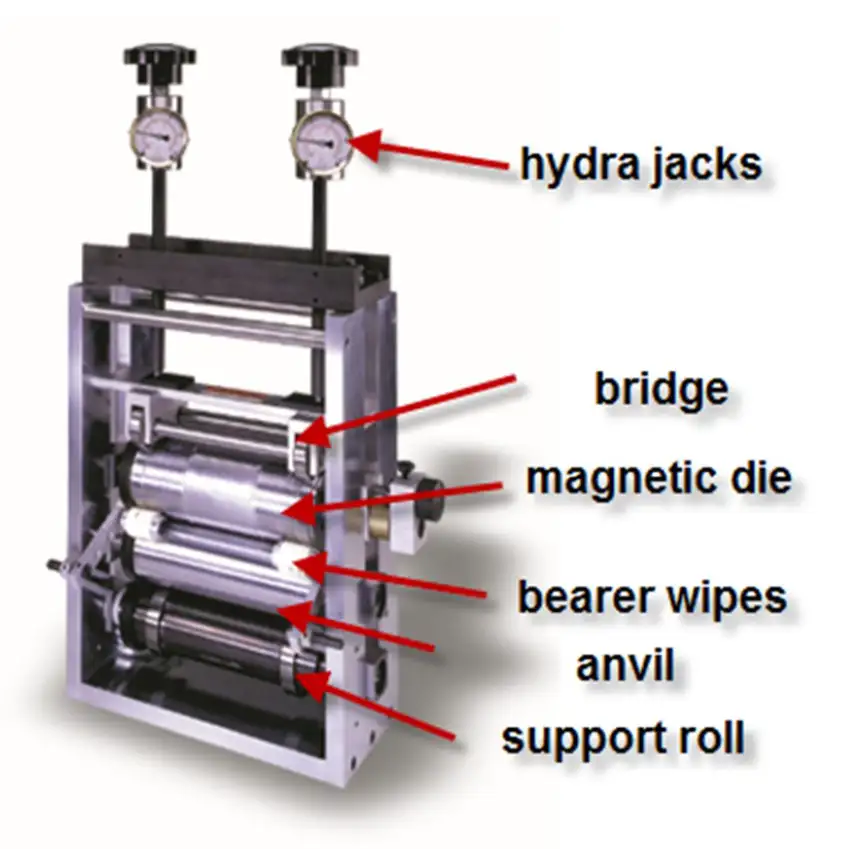

Regularly scheduled maintenance for all parts is important (see Figure 2), but focus on these areas when evaluating the condition of your die station:

- Press frame and die slots

- Bearing blocks

- Hold-down assemblies

- Anvil roller

- Lubrication methods

In addition to regular press maintenance, operators need to understand, carefully control and maintain temperatures to ensure proper thin-film conversion (see Figure 3). As temperature plays a critical role., it is important to understand the impact of many temperature variables, such as:

- Conventional hot-air drying

- UV lamps

- Distance between heat source and cutting tools

- Use of chill rolls

- Manufacturing plant environment

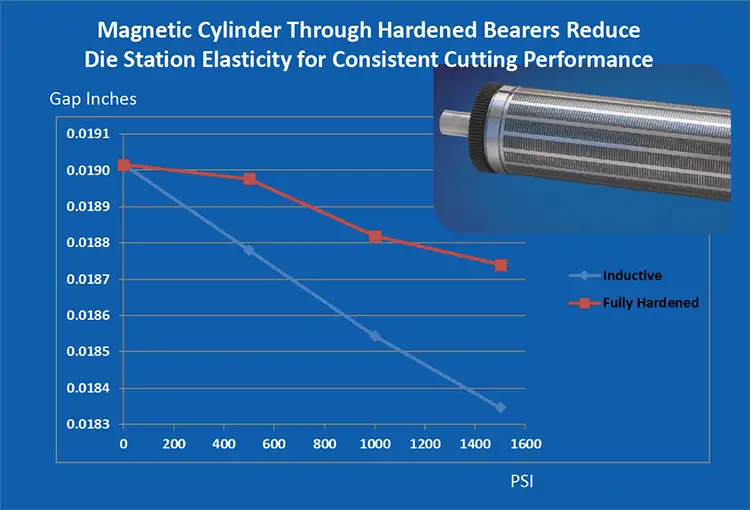

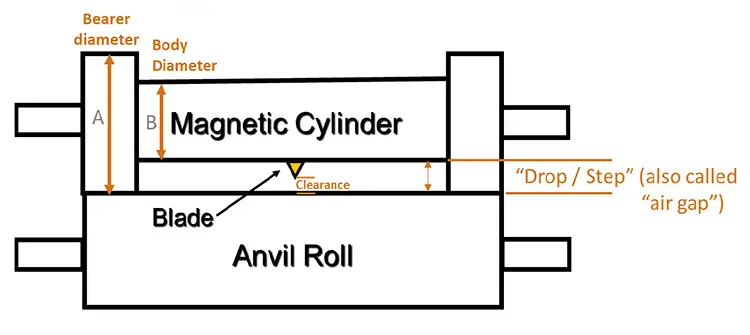

While all temperature changes impact the web, increased temperatures lead to thermal growth (expansion) of many parts, but temperature affects all components in the die station and a little heat can cause a lot of trouble if not controlled properly (see Figure 4). Web motion causes the temperature of the web to increase, particularly in thin-film materials. Higher web temperatures also cause thermal expansion of parts, creating a change in the die-to-anvil clearance. This results in uneven cutting across the web, lifting the rotary die off the anvil as the bearers warm up (see Figure 5). This can be managed through special designs in the magnetic-cylinder bearers and the implementation of cooling systems for the steel rolls.

Optimizing thin-film rotary die-tool design

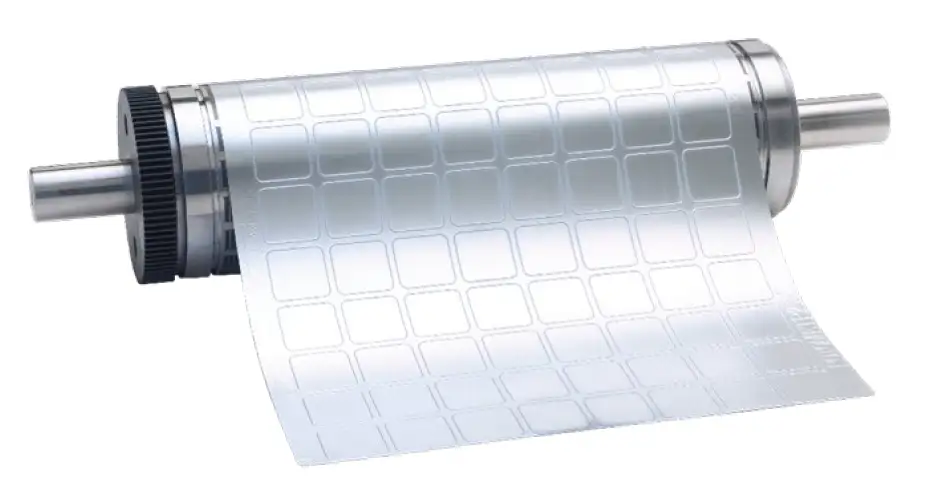

Whether you choose solid rotary tooling or the combination of magnetic cylinders and flexible rotary dies (see Figure 3), the die must have consistently tight tolerances. It is important to work closely with your die maker to optimize layout recommendations, consider wider bearer options and evaluate design options such as staggering rows, skewing shapes, bowing shapes to soften the die cut, improving die life and assisting with stripping efforts.

While solid rotary tooling provides a solid option for thin film, flexible dies combine with complementary magnetic cylinders create the greatest flexibility in thin-film conversion. Magnetic cylinders are important to create the perfect cut. They must be routinely audited; the verified undercut must be established to set the benchmark on the flexible-die TPH (Total Plate Height), and the surface must be free of all imperfections. This firm’s proprietary flexible-die technology ensures the right die for the right application; our JBA design and in-house hardened heat-treatment process provides optimal performance with minimal thermal expansion for precise cutting of thin-film materials from your flexible dies (see Figures 4-5).

Finishing touches of machine harmonics

Operators also should ask how smooth is my machine running? Is it servo-driven vs. line-shafting with gear boxes? To maximize any press performance, lubrication of the bearers and bearings at the start of every job is critical as they must maintain lubrication throughout the press run. This assists in heat control and reduces wear by minimizing the “scrubbing” or “chatter” of bearer surfaces between the die and the anvil. Also by cleaning and lubricating all gears in the machine often, operators will reduce heat and friction, plus eliminate roll chatter.

On the non-mechanically driven side are the idler rolls. Harmonics or web instability can exist if the idler-roll systems’ “conveyance” of the web is inconsistent. This firm’s patented technology is said to provide industry-leading methods to eliminate instability issues.

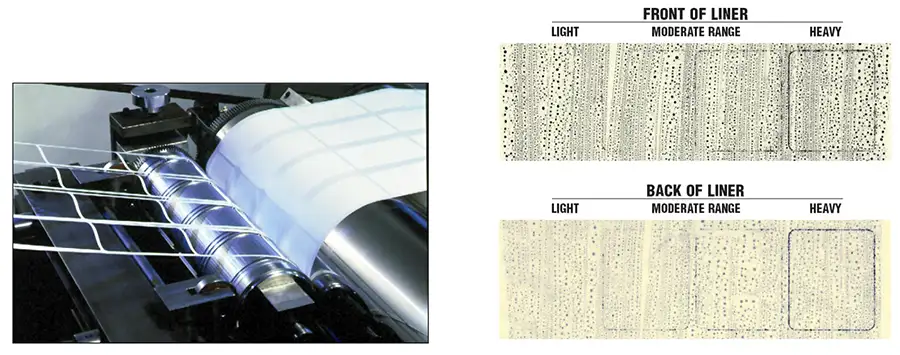

Almost all thin-film converting operators are interested in a light liner strike to ensure high roll quality for their customers (see Figure 6). Consistently achieving target liner strike can be difficult, but this firm’s comprehensive portfolio of solutions helps customers achieve optimal outcome. Anvil options, including standard, adjustable parallel anvils and dual adjustable (parallel and single side in one) are all capable of providing the versatility to handle the variability that naturally accompanies thin-film conversion. At the end of the day with thin film, however, a high-quality standard anvil is highly recommended for challenging conversion to minimize operator error and volatility.

End of the Line: Waste/matrix removal of thin-film materials

Liner-strike analysis reveals areas where thin liner converting may need help in the stripping process. Operators should try different diameters or types of stripping rolls. This firm’s broad range of roller offerings assist in keeping the matrix moving correctly and avoiding label lifting with patented roller designs, coverings, coatings and designs. Also, consider changing the angle of removal to eliminate potential label lifting. As with all components, stripping rolls and supporting solutions must be maintained.

Conclusion

Myriad factors influence die-cut quality and production output, including web tension, running speed, material, die-station stability, pressure settings, layout of the label images, deflection of the cylinder, the stripping roll and friction/temperature. While thin-film label face stocks and release liners can pose challenges to converters, this firm and its partnering OEMs are investing significantly in R&D, automation and other Industry 4.0 solutions to improve the performance of new and old presses alike to help converters work better, faster and smarter today and in the future.

Butch Schomber, global business development mgr. at Maxcess RotoMetrics, has been serving the rotary diecutting industry for over 40 years. He started with the company more than 20 years ago as a territorial account manager, and for the last 10 years, Butch has turned his field expertise toward product development and innovation. Working closely with tech support, web fab and the sales team, he continues to develop solutions to the day-to-day issues customers experience. Butch has been recognized for his industry contributions by IADD, the Labelexpo Series and many other industry organizations. He can be reached at 314-856-8491, email: bschomber@maxcessintl.com.

Paul Young, narrow-web account mgr. focusing on RotoMetrics rotary-tooling solutions, has over 25 years of experience in narrow-web converting markets. He previously worked for Electro Optic and is considered one of the leading subject-matter experts when it comes to flexible rotary-die technology and supporting solutions. Paul has been on the forefront of converting thin films in the label industry. He can be reached at 678-314-8626, email: pyoung@maxcessintl.com or www.maxcessintl.com/rotary-dies/.