By Robert Rae, managing dir.-Sales; Ryan Turner, R&D engineer; and Jennifer Heathcote, business development mgr. GEW

Editor’s Note: Part 1 of this technical paper (CQ 2021 Q3, page 41) covered various countermeasures for oxygen inhibition, and inert-chamber components and their operation.

UV-curing system

The emitted wavelengths and UV dose incident on the coating is a factor of the UV-system design, power settings, regular maintenance and web speed. Photoinitiators in silicone-release coatings typically respond best to UVC radiation; although, development activity using UVA photoinitiators is increasing. Reactivity to UVA is necessary for curing with commercially available LED systems.

Due to low coatweights, UVC dosage for effective cure of silicone release is relatively minimal compared to that required for other coatings and densely pigmented inks with thicker laydowns. An amount of 10 mJ/cm2 often is sufficient (UVC as measured using EIT PowerMap II detectors and filters). So, it is not necessarily the power and specification of the UV lamp which is most important; it is the ability to accurately control UV output over time and with web speed, mitigate contamination and implement good maintenance practices. Both contamination and insufficient maintenance significantly alter lamp output, and faster web speeds result in reduced UV exposure. Integrated inline control methods such as UV monitoring are additional tools that are extremely beneficial for reliable lamp control.

Medium-pressure mercury arc-lamp systems are comprised of consumable parts that degrade with time and use. This ultimately results in reduced UV output relative to installation date. Additionally, inert UV systems consist of elements outside the UV lamphead, which are integral to system performance but also contribute to changes in UV output if not maintained.

Benefits of good maintenance, clean air

Arc-lamp output degrades over time due to electrode deposition as well as devitrification and solarization of the quartz tube. Degradation in UV output is not equally balanced across UVC, UVB, UVA and UVV bands. In fact, shorter UVC wavelengths deteriorate more rapidly than longer wavelengths. Furthermore, devitrification of the quartz is accelerated by contamination and humidity. Fortunately, when lamps are proactively kept clean and the system and environment are properly maintained, lamp life is prolonged.

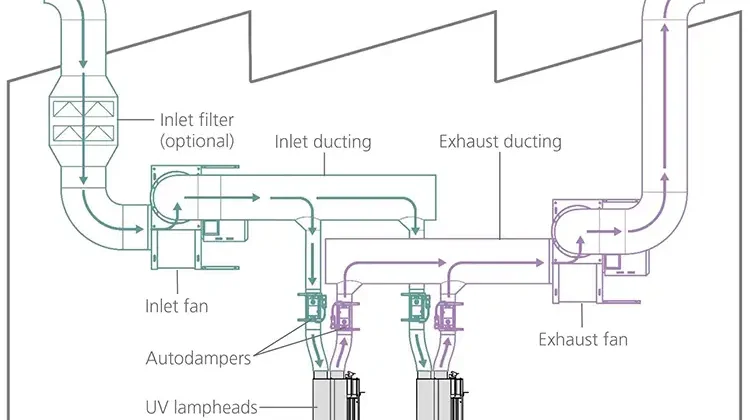

For inert systems, the lamp normally is separated from the coating by at least one quartz plate. Contaminants present in plant air can deposit on the lamp, reflectors and quartz plate whenever plant air is used to cool lamphead assemblies. Therefore, conditioning of cooling air to remove contaminants extends lamp life. This is accomplished with a “positive purge” system integrated with the lamphead assembly (see Figure 5). Additionally, the lamp itself can be cleaned periodically before eventually being replaced.

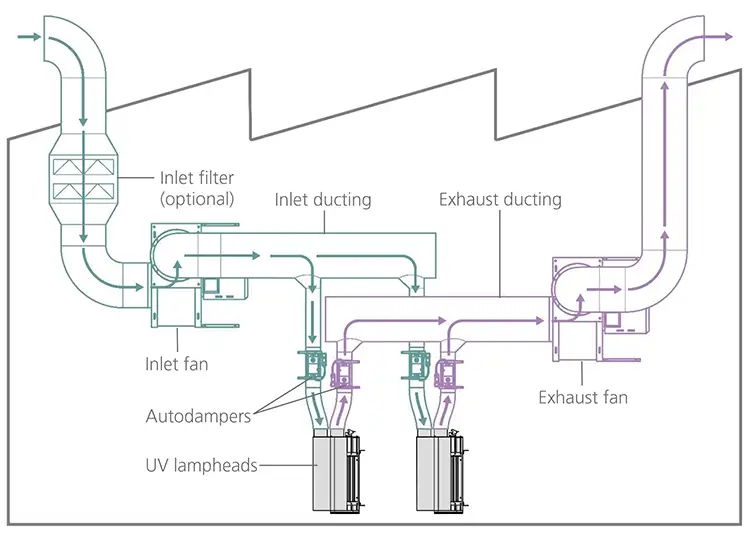

More than 70% of all UV energy emitted from electrode arc-lamp assemblies interacts with the reflector system (see Figure 6). This highlights the importance of reflector maintenance as compromised reflectors significantly reduce reflected UV energy. Photos showing new and contaminated reflectors can be seen in Figure 6. As with lamps, contaminated cooling air is the main driver for reduced reflector performance. Reflectors should be properly cooled and cleaned periodically to ensure performance. It should be noted that reflectors typically have a longer life than lamps as their deterioration is not intrinsically tied to operation.

Quartz plate(s) separating the lamphead and inert chamber deteriorates in identical ways to arc lamps in terms of devitrification and solarization, leading to reduced UV transmissivity. The web-facing side of the quartz plate also is susceptible to additional contamination sources, such as coatings and substrates. Quartz plates should be cleaned periodically as instructed in maintenance manuals before eventually being replaced.

Cool off with temperature control

The UV output of a medium-pressure arc lamp is coupled with its temperature. As a result, it is prudent to appreciate that changes in lamp cooling can impact performance. Cooling issues normally manifest as undercooled systems. In other words, lamp temperatures increase, which reduces UV output. Elevated temperatures cause arc lamps to operate outside their ideal window. In severe cases, lamps will bend, sag or bulge, which further reduces UV output. High temperatures also cause changes in reflector behavior as dichroic coatings, designed to absorb infrared energy, delaminate and deteriorate.

For air-cooled systems, ducts often become blocked internally with contamination or are obstructed by ductwork collapses, severe bends and too small spaces. Installations using conditioned air can experience issues when clogged filters decrease flowrates. UV systems with combined air and water cooling usually are more robust. Commonly experienced cooling issues, such as duct movement or partial blockage in air-cooled systems, can be overcome in water-cooled systems by increasing the cooling duty of the water. Nevertheless, water systems must be regularly maintained. As a precaution, properly engineered UV systems are designed to monitor lamp temperature and power to ensure consistent operation at appropriate levels.

Checking on UV energy incidence

Despite adherence to good and regular maintenance, there is no substitute for monitoring UV energy incident upon the coating. Doing so removes all uncertainty associated with lamp output. Commonly used offline tools include color-changing, dose-monitoring “strips” and UV radiometers that periodically compare lamp output to an established UV-calibration source. Unfortunately, dose strips respond primarily to UVA wavelengths, which render them a relative measurement tool only, and radiometers are physical devices with bulky form factors that make it impossible to pass them through UV assemblies or transport them with the web.

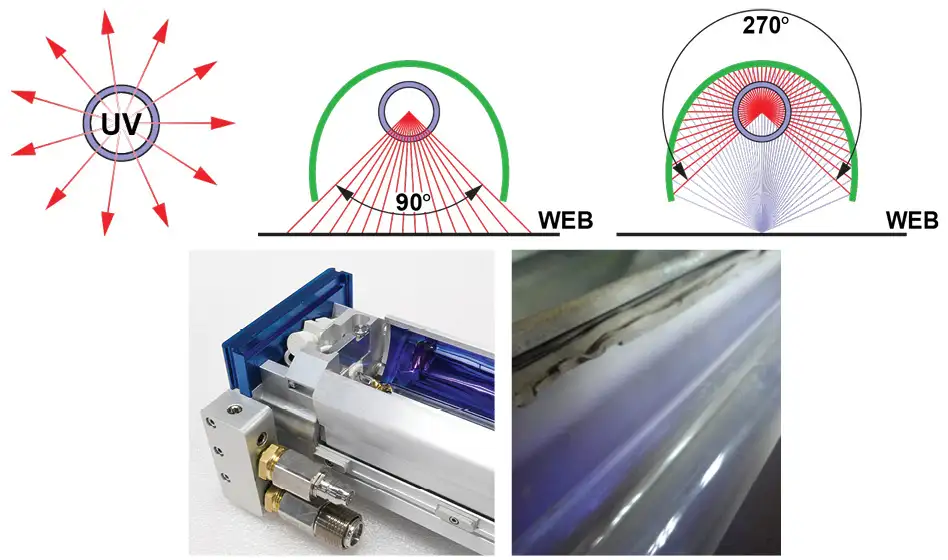

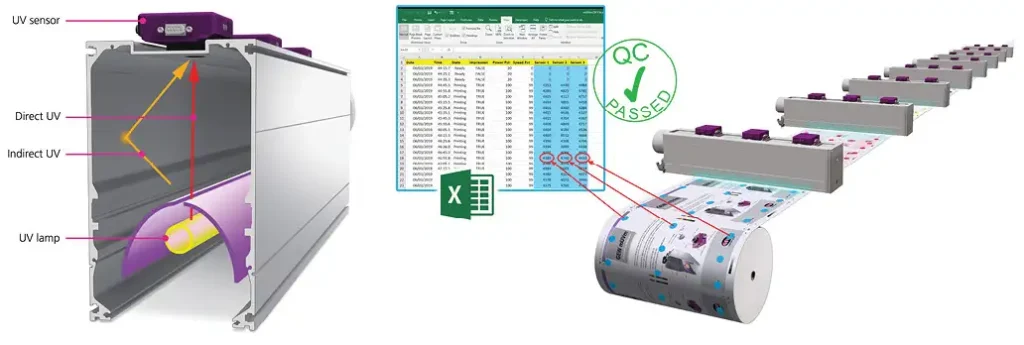

The best practice available today is to use in-line UV monitors to continuously measure UV output at given positions along lamp lengths (see Figure 7). One or multiple sensors can be placed along a single lamp to record output at the edge, center or in between locations. Integrated electronic systems monitor UV-output levels and adjust system power accordingly to ensure consistent dose levels are delivered to silicone-release coatings at all times.

Conclusion

Curing silicone-release coatings with ultraviolet energy is established technology. It enables narrow-, mid- and wide-web converters to rapidly set coatings in small footprints at high web speeds while also producing performance properties superior to what is achievable with alternative processing methods. To the benefit of converters, this transformation occurs within a fraction of a second, provided UV formulations are exposed to correct levels of UVC-energy density (dose) inside inert chambers. Inert chambers reduce oxygen concentrations at coating surfaces to prevent molecular interference within the chemical-crosslinking reaction and enable the production of low-release materials.

Once cured, coatings exit UV-curing stations and the web is immediately ready for further processing, sheeting, slitting, rewinding and shipping. Proper engineering design, maintenance and monitoring of UV-curing and inert-chamber systems are essential for ensuring long life and consistent cure of release coatings over time. All of this keeps work-in-progress goods out of inventory, reduces scrap and facilitates quicker lead times.

Jennifer Heathcote, business development mgr. at GEW, Inc. (North Royalton, OH), holds a Bachelor of Science in Mechanical Engineering from Purdue University and an MBA from the Fisher College of Business at The Ohio State University. She can be reached at 440-381-5606, email: jheathcote@gewuv.com, www.gewuv.com.

Robert Rae, managing dir.-Sales for GEW (EC) Limited, holds a Master of Chemistry from Durham University. Ryan Turner, an R&D engineer for GEW, holds a Master of Engineering in Mechanical Engineering from the University of Exeter. Both are based at the GEW headquarters in Crawley, West Sussex, UK. They can be reached at +44-1737-824-500, sales@gewuv.com.