By Frank Förster, Ph.D., head of process development for atmospheric-pressure plasma, SOFTAL Corona & Plasma GmbH

Atmospheric-pressure plasma is highly suitable for treating the surfaces of thermally sensitive polymers. This method also can process materials of any desired thickness and offers a replacement for wet-chemical adhesion promoters.

Introduction

Atmospheric-pressure plasma and corona technology have been widely used for many decades for surface treatment in extrusion and converting of polymers. Atmospheric-pressure plasmas continually open up new fields of application, including the adaptation of plasma sources, broader options in materials and geometries, and plasma-induced surface functionalization. This paper describes two methods of atmospheric plasma for web processing, converting and more.

The aim of corona treatment is to adjust the surface energy in a controlled way so as to improve the adhesion of inks, lacquers, adhesives and coatings. The volume properties of the polymer matrix are not changed. Benefits include easy, process-controlled operation; high efficiency; and low costs.

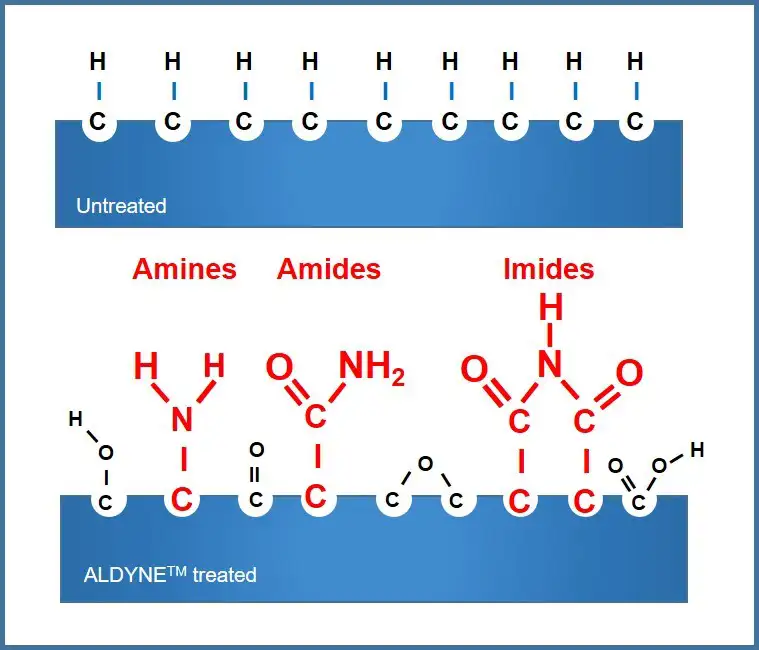

During pretreatment, plasma activates a large number of chemical reactions in the air within the electrode gap and on the polymer surface. The result is the chemical bonding of functional groups, such as hydroxides, ketones, ethers and carboxylic acids, to the polymer surface.

These are polar groups and increase the surface energy. However, in practice, conventional corona technology is limited to two-dimensional materials with thicknesses of only a few millimeters.

Method #1: Linear plasma surface treatment

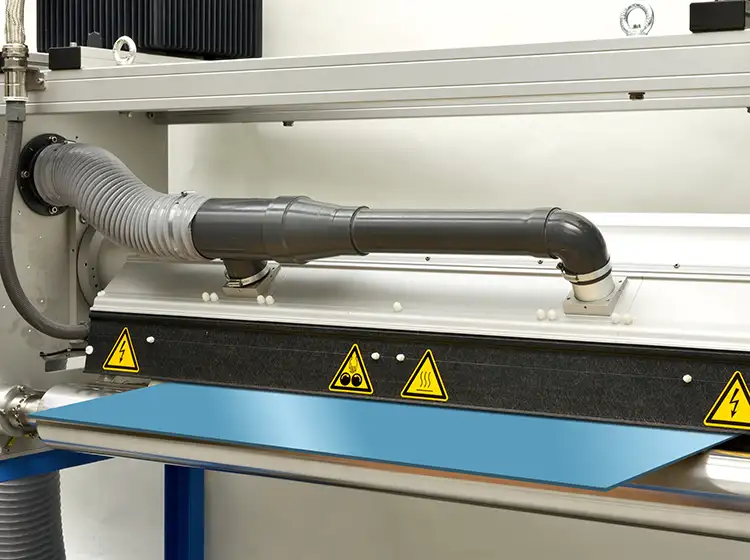

For the first time, plasma surface technology allows materials of unlimited thickness to be treated (see Figure 1). Linear plasma treatment modifies the surface of plastic sheets, polymer foams and composites in the sub-nanometer range, so that adhesives, printing inks, lacquers and other coatings reliably adhere (see Figure 2). High-efficiency plasma sources also allow the treatment of highly thermal-sensitive materials. Multiwall panels or honeycomb structures also can be activated in this way.

In open-pore foam, there is no risk of localized preferential discharge, and closed-pored foams are not perforated (see Figure 3). Furthermore, the edge regions are not damaged by the plasma discharge, and it is not necessary to adapt the material width to the electrode width. In addition, linear plasma can be installed in existing polymer-extrusion and R2R converting lines.

Method 2: Surface treatment via a controlled-gas atmosphere

This method uses plasma surface treatment in a controlled-gas atmosphere and achieves the efficiency of wet-chemical coating processes at a fraction of the cost. Gas plasma permits targeted control of the chemical processes that take place in the plasma discharge and, ultimately, on the surface of the substrate. As a result, functional coatings are the thickness of a monolayer (typically 0.3 to 0.4 nm) comprising, for example, amide, imide and amino groups, which are covalently bound to the outermost polymer chains. These functional groups allow the polymer to bond to adhesives and other coatings (see Figure 4).

In many applications where adequate bonding is not possible using corona treatment, adhesion-promoting liquid primers are used. This increases manufacturing costs for primer, the production process and the removal of organic solvents. Treatment in a controlled-gas atmosphere offers an alternative to liquid primers on polymer surfaces such as polypropylene (PP), polyethylene (PE) and polyethylene terephthalate (PET). In comparison to liquid priming, under normal production conditions, this process can cost only a tenth of treatment with conventional primers.

No liquid or solid materials are involved in the surface treatment; therefore, no residues and contamination can be deposited. Because no solvents are involved, there also is no need for cleaning and drying – or the associated downtimes – and no residual adverse effects on the substrate material. The process gases required for the gas-atmosphere plasma process are harmless to health, non-hazardous and environmentally safe.

Water-cooled electrodes for high plasma output

The gas-atmospheric plasma system (see Figure 5) incorporates water-cooled electrodes. These allow high plasma outputs to be achieved without harming the material. The chemical processes at the material’s surface are intensified by the concentrated plasma discharge. Furthermore, gas-plasma stations can be supplied in any desired web sizes and speeds.

Conclusion

The numerous benefits of plasma surface-treatment technologies are clear. Linear plasma is capable of surface-treating thick and thermally sensitive materials, such as polymer foam, plastic sheets, corrugated panels, composites and more. Gas-plasma methods use energy to molecularly restructure the surface of substrates, eliminating the use of primers and solvents, to achieve powerful bonding. These methods are highly reliable in raising adhesion for finishing, bonding and decorating processes while also being safer and less expensive.

Frank Förster, Ph.D., is head of process development for atmospheric-pressure plasma at SOFTAL Corona & Plasma GmbH (Hamburg, Germany). He holds a doctorate in Physical Chemistry from Clausthal University of Technology in Germany and has been with SOFTAL for 28 years. Frank can be reached at +49-40-753-08-170, email: ffo@softal.de. SOFTAL is represented in North America by 3DT LLC of Germantown, WI. Contact the company at 262-253-6700, email: sales@3DTLLC.com or www.3DTLLC.com.