By Fabiano Rimediotti, senior technologist; and Raffaele Guadagno, process & technology specialist, Nordmeccanica-Vacuum Div.

Thin films deposited by vacuum coating, with their unusual properties of being extremely thin and relatively impervious to the diffusion of gas, water vapor and aromas, lend themselves to being ideal components for future recyclable packaging. This article will describe the main trend in vacuum deposition, including the development of barrier solutions for mono-material packaging based on polyolefins – in particular, oriented polyethylene (OPP) – and on the integration of vacuum and atmospheric coating. The topic will be illustrated and discussed from our firm’s latest experience on multiple sources, materials and solutions with pilot trials at the recently implemented demonstration center.

Trend to sustainable flexible packaging

There is a worldwide trend toward sustainability, and Europe is the geographical region with long-standing, enforced legislation and practices on environmental issues. Following the publication of the European Union’s “Waste Framework Directive” in 2008 (updated in 2018), in which a hierarchy was defined in the treatment of waste (often represented in the form of an inverted pyramid), the terms of this hierarchy, “Prevention, Re-Use, Recycling, (Energy) Recovery, Landfill,” have become reference terms for environmental sustainability practices in all sectors.

The objective set for all EU member states (“Circular Economy Package”) is that 100% of plastic packaging must be reusable or recyclable by 2030; some members have set themselves intermediate goals (e.g. Germany, 63% within 2022 – Verpackungesetz 2017). Some large Asian countries recently have introduced, into national legislation, even more drastic goals (see India with its ban on single-use plastic by 2022, and both India and China with bans on waste-plastic imports from abroad to recycle into new products).

Many global brand owners have made public commitments to achieve and even surpass government binding targets. Various associations have been formed, such as the Ellen McArthur Foundation (EMF), the “Circular Economy for Flexible Packaging” (CEFLEX) and the “Polyolefin Circular Economy Platform” (PCEP), all engaged in promoting, supporting and publicizing initiatives and projects to reduce the environmental impact of the materials (polymeric films, adhesives, inks, etc.) that constitute flexible packaging.

More recently, various companies and institutions have been established to substantiate and coordinate the many initiatives taking place, providing members with guidelines for specific materials and applications [1], or auditing and certifying solutions for recyclability. Major industry players have announced initiatives and pledges for their transition to a circular economy; these can be interesting and even inspirational for all industry and are found in news and public access publications, such as Converting Quarterly. In one of our previous presentations, there was a short but representative list [2].

From these examples and many other cases, we can summarize the approach to more sustainable packaging, through the following directions:

- Recyclability mainly obtained from mono-material packaging or from easy layer separation into chemically homogeneous fractions;

- Biodegradable materials are a choice despite all the relevant limitation in terms of properties and durability;

- Use of a significant and growing quantity of recycled material to feed the production line; and

- Replacement of plastics with paper-based substrates on selected applications.

Vacuum-coated films for mono-material packaging

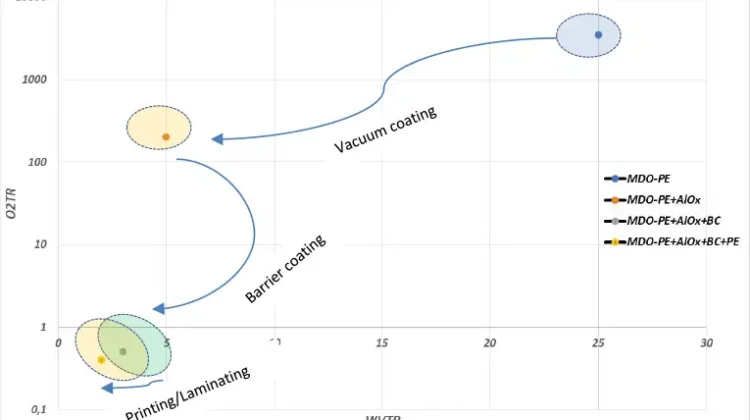

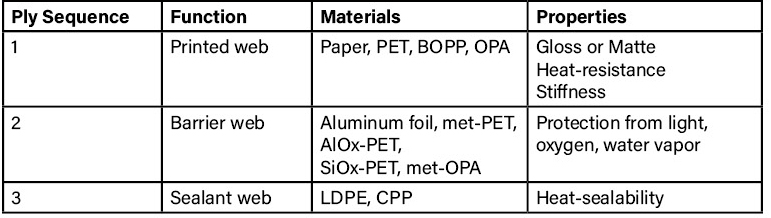

The general trend toward recyclable packaging prompted many projects for replacing multilayer packaging with mono-material structures. The most classical and universal concept of barrier packaging nowadays is represented by the three-ply film compound, schematically represented in its general functional configuration (see Table 1).

Metallized and vacuum-coated films represent the typical barrier film, and this article will describe examples of more sustainable solutions to replace the traditional, multilayer and multi-material packaging and the challenges to maintain equivalent properties and reasonable production costs.

Typical examples can be the substitution of metallized-PET with metallized-BOPP. A typical three-ply structure would become printed OPP//met-OPP//LDPE with the advantage of all-polyolefin components or, even, an all-polypropylene structure, if introducing CPP as the sealant layer. To retain the same or similar barrier, the oxygen transmission of the met-BOPP should be considerably reduced to approach the typical met-PET properties which, in conventional products, is from 20-50X better performing. A step forward and an even more challenging solution is all-PE structures by introducing a high-barrier polyethylene. The same trend occurs for metallized films and for clear barrier packaging. The machine-direction oriented-PE (MDOPE) is, in fact, one of the most likely candidates to become the backbone of fully recyclable, mono-material compounds.

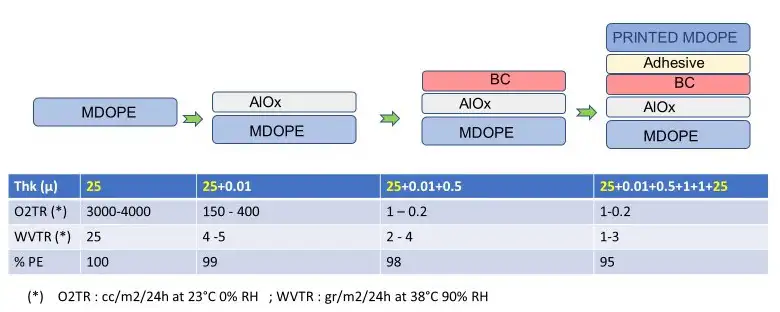

Figure 1 shows a target mono-material packaging application which would match the full recyclability pledge as stated by specialized organization and institutions [1,3]. The published criteria to define a certain compound as “recyclable” are not unique, but there is a common understanding that 95% content represents a safe compatibility level for recycling streams. Data shown in Figure 1 are typical and representative of already existing material properties as tested by the authors’ group. Extensive trials are in progress at the end-user level to prove the real-world applicability of the new materials to selected packaging segments.

The case of MDO-PE as a clear barrier

The material-process flow shown in Figure 1 represents a two-ply basic packaging with MDOPE playing the role of substrate for the three basic functional properties defined in Table 1 (printed / barrier / sealant web). A more complex three-ply structure, adding a laminated, sealant LDPE would be possibly preferred for selected applications without weakening the described recyclability concept.

The first process step is AlOx deposition on MDOPE film. The one-direction machine stretching after the extrusion and blown-film making process imparts mechanical strength and some degree of stiffness and better clarity to the polyethylene, while still retaining typical properties such as low sealing temperature and puncture-resistance. Likewise, the improved surface properties and thermal stability enhance barrier properties after film coating, as well. Therefore, the polyethylene, typically and broadly used as a sealant in common multilayer packaging, after orientation can be metallized, printed and laminated as it is commonly done for PET and BOPP.

AlOx stands for aluminum oxide, and it currently is one of the most popular clear or transparent barriers. It consists of an oxidation of the evaporated aluminum by means of oxygen gas. As for conventional metallization, aluminum wire evaporates from heated ceramic bars or boats; oxygen gas is fed to the evaporation area with finely controlled distribution, depositing a transparent oxide layer on the PE film. Main factors in determining the product’s properties are deposition thickness (very thin – around 10 nm) and oxidation degree. Moreover, the film material properties play a fundamental role.

For polyolefin-based materials, the gas-barrier properties achieved by means of vacuum-deposited thin film cannot match the traditional barrier film of metallized-PET, and an additional coating is needed (see “BC” for “Barrier Coating” in Figure 1).

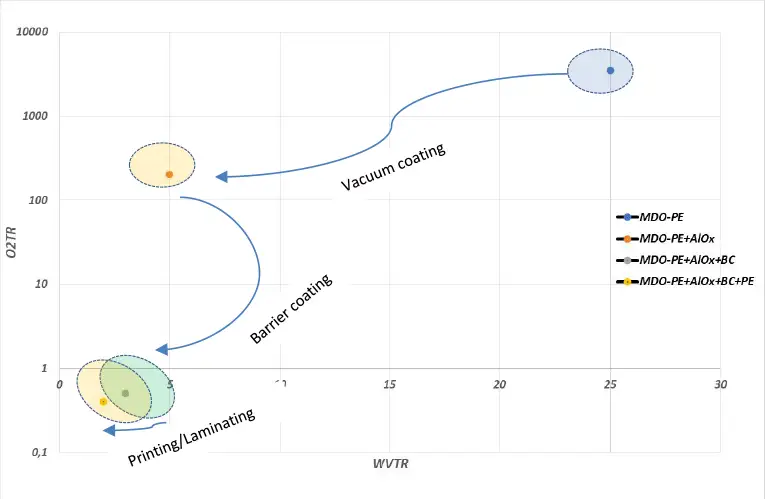

Figure 2 represents average data from multiple trials on MDOPE from different sources. It is apparent from the data spread that film formulation and production process have significant influences on determining the end product’s properties. Coating and varnish manufacturers have developed new products specifically designed for high-barrier applications. Our group has used water-based coatings which efficiently complement the vacuum-deposited film’s properties.

The Figure 2 graph shows the significant gas-permeability drop after AlOx and barrier-coating application. Data refer to MDOPE with clear barrier AlOx, but similar behavior was found for BOPP and for metallized-polyolefin films. In general, with a half-micron of top-coating, corresponding to about 0.5 gsm of application on an AlOx-coated MDOPE, the oxygen barrier is below 1 cc/m2/24hrs, representing the benchmark for high-barrier materials.

In the case of transparent barrier film shown here, the water-vapor permeation gain from AlOx and barrier coating is less outstanding. While it is improved by lamination and is therefore sufficient for several products, improvement in polymer formulation as well as barrier coating are needed for more-demanding, moisture-protecting applications. This limitation does not apply to metallized structures because the aluminum layer on polyolefin has high-barrier properties.

Industrial applications: Opportunities and challenges

The vast industry interest in a mono-material solution for flexible packaging is demonstrated by the number of new investment projects and feasibility studies. The case of oriented-PE is very representative of this trend. The potential advantages and opportunities can be summarized as follows:

- Polyethylene films are being produced and used in thousands of tonnes for multiple applications and, considering the circular economy demand, the PE recycling streams exist and are well established.

- Production lines for PE film, blown or cast, are virtually everywhere and can be installed with moderate investment.

- The MDO units can be installed as a modular addition to blown-film lines. The process improves the film’s mechanical, thermal and optical characteristics.

- MDOPE can be vacuum-metallized, coated, printed and laminated with superior efficiency and performance in terms of barrier, printability, stability in bag- and pouchmaking, etc.

- There are still significant challenges to develop all-PE solutions to replace traditional multilayer packaging, encompassing the entire production chain. In this article, we mention only those more relevant to the film-converting phases.

- MDOPE quality and properties need to be designed and tailored for the demanding processes and application requirements. Polymer formulation, surface properties, integrity from defects and roll-formation quality need to be optimized. As suggested from the qualitative graph in Figure 2, there is much to do to achieve film-property consistency to expect high performance.

- The results of three years of trials demonstrate the technical feasibility of a mono-material packaging for multilayer and multiple-material replacement. Obviously extensive qualification tests are needed to prove the actual solution viability.

- Industrial production of mono-material alternatives can be possibly more expensive than existing products. This issue must be addressed in the framework of the general policy driving the shift to a more-sustainable packaging business; however, efforts are needed to optimize the material, coating and process costs.

Future actions and conclusions

This article described the general results of extensive trials for mono-material packaging solutions with particular focus on mono-oriented polyethylene vacuum-deposition, coating, printing and lamination. There are promising indications for the feasibility of a future substitution of existing materials with more-sustainable packaging, but the new material qualification projects have just begun and need significant work by all players in the product value chain.

Our firm’s fully integrated testing and demonstration platform, comprising vacuum-metallizing, coating and laminating machines, is already cooperating with many industry partners for testing materials, proving new ideas or custom-tailored solutions, and simulating end-product properties and performances. Networking with industry partners along the production chain, including polymer manufacturers, coating suppliers, end-users, and research and qualification institutions, already is in place and will be instrumental to progress toward successful solutions.

References

- https://Recyclass.eu/guidelines/

- F. Rimediotti, C. Scarica, “The role of vacuum coating in the quest for more-sustainable flexible packaging,” AIMCAL R2R USA Conference, Oct. 2019.

- https://ellenmacarthurfoundation.org, https://ceflex.eu/

Fabiano Rimediotti, senior technologist at Nordmeccanica-Vacuum Div. (Piacenza, Italy), holds a university degree in Chemical Engineering. He has spent most of his professional career in the field of vacuum technology, in particular, vacuum metallization. Fabiano worked for more than 25 years at the Galileo Co., specializing in the design and construction of vacuum metallizers for flexible-packaging and numerous other applications. He joined Nordmeccanica Group when Galileo Co. was merged with the Nordmeccanica-Vacuum Div. Fabiano can be reached at +39-523-596411, email: [email protected], www.nordmeccanica.com.

Raffaele Guadagno, process and technology specialist at Nordmeccanica-Vacuum Div., holds a degree in Chemical Engineering from the University Federico II of Naples in 2014. He worked as process engineer at Manucor S.p.A. (Italy), the largest BOPP-film production plant in Europe, from 2015 to 2020. Since then, Raffaele has specialized in the process and technology of vacuum metallization of flexible film and paper at Nordmeccanica. He can be reached at +39-523-596411, email: [email protected].