By Tom Gilbertson, vp-Application Engineering – Corona Treating Systems, and Mark Plantier, vp-Marketing & Communications, Enercon Industries

Did you know that poor web handling creates trouble for corona surface-treatment operations? It often is the hidden root cause of suspected treatment issues and can lead to significant downtime. As converters run higher line speeds with thinner films, greater attention is required to guarantee proper web handling. In addition to inconsistent and/or backside treatment, improper web handling can cause film scratching, film stretching and generate static issues throughout the line. The good news is you can avoid these problems by properly defining application specifications so your corona-treater supplier and OEM can employ the optimal web-handling techniques needed to ensure trouble-free treatment. This article will explore when to employ various web-handling tactics, including web-path optimization, idler rolls, nip rolls, ground-roll coatings, drives and static-elimination equipment.

Why the web path in and out of a corona treater matters

Corona treatment increases the surface energy of films to enable wettability and bonding of inks, adhesives, coatings and laminations. Corona is created by discharging high-frequency, high-voltage energy across a metal or insulated electrode mounted above a grounded roll. The air between the electrode and grounded roll is ionized and is visually identifiable as a purple glow.

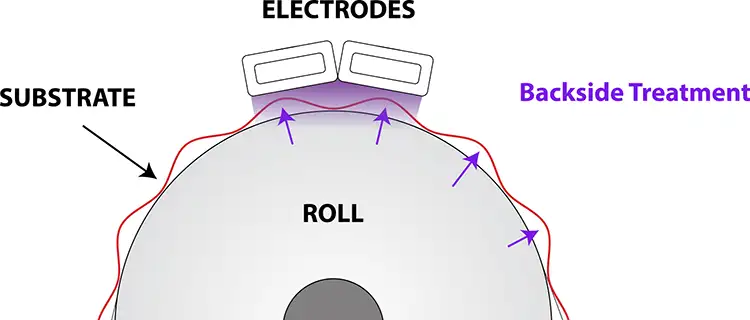

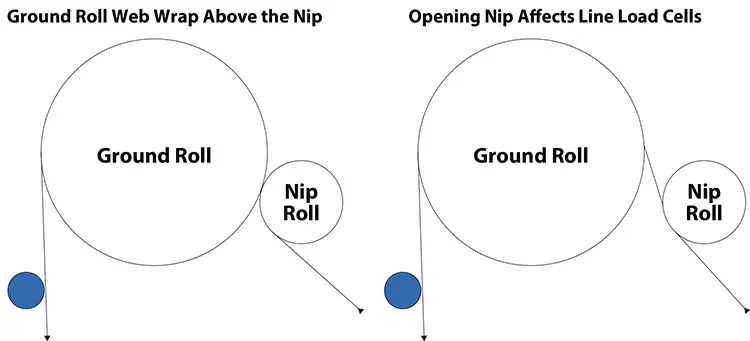

As film passes through the air gap, the top of the film receives treatment. However, if air is allowed between the back of the film and the grounded roll (see Figure 1), backside treatment will occur. Backside treatment can create two issues for converters. First, the side of the film that is intended to be treated may not receive the full amount of required treatment. Second, treatment of the backside of the film may be undesirable and create problems.

Your first line of defense against backside treatment is a proper web path in and out of the corona treater. As the film passes through the air gap, it should wrap flatly around the ground roll, ideally with 180° of contact. Figure 2 shows how idler rolls are used to create a natural path to achieve the desired web wrap angle.

The surface of the ground roll can have an impact on how well the web wraps and holds flat against it. For example, in comparison to a bare roll, one of the benefits of this firm’s high-definition corona system is that its proprietary ceramic-roll covering provides additional insurance against film wrinkling and backside treatment.

Considerations for higher line speeds

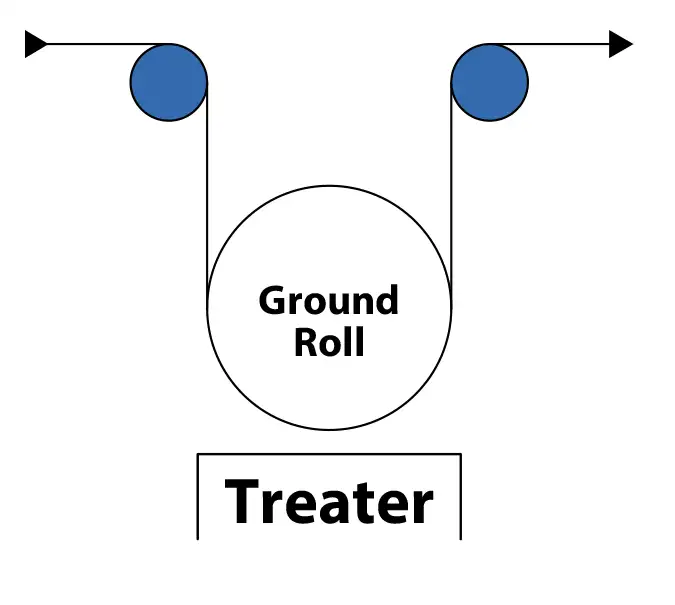

As you run your lines faster, there is greater laminar airflow that rides along with the web. This air cushion can make it difficult for the web to follow the path in a completely relaxed manner. Moreover, if that causes the web to have a wrinkle, a bag or baggy edge, then it will not rest properly on the ground roll.

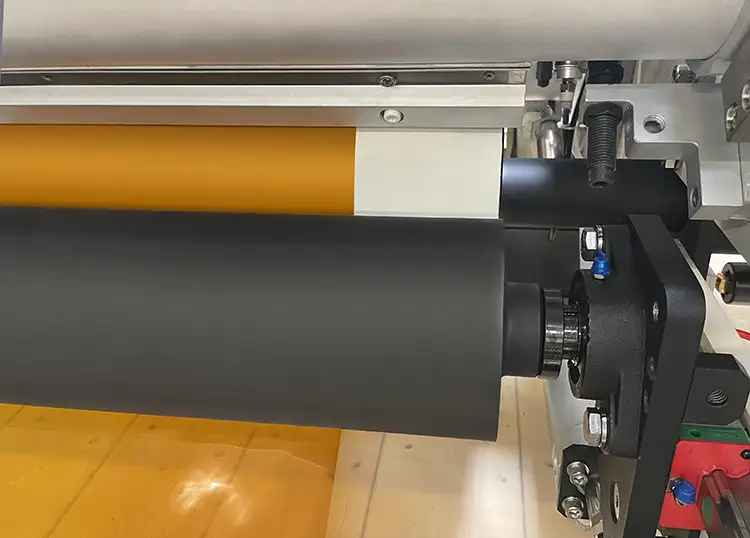

In this case, a nip roll can be employed to flatten the film before treatment (see Figure 3). When engaged, the nip lays on the ground roll and squeegees out the air between the web and the treater roll, reducing the possibility for backside treatment.

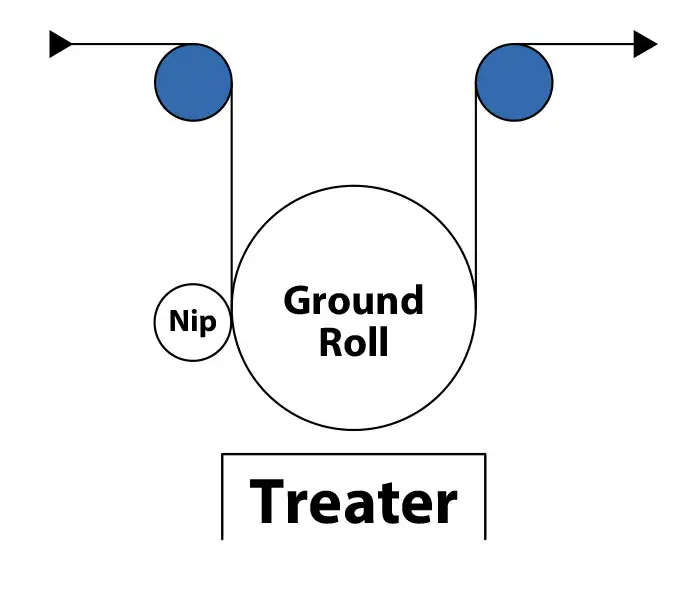

Proper positioning of a nip roll prior to treating

Position of the nip roll to ground roll is critical to web tension and uniform treatment. In Figure 4, a nip roll is shown in an open position (right), affecting line load cells. When it closes (left) and pushes the film against the ground roll, the web wrap begins above the nip. This nip-roll position can lead to film wrinkling and film stretching. A nip roll engaged against a treater roll also will hold a firm tension as the film receives corona treatment (see Figure 5).

How a lack of maintenance leads to web-handling issues

When a corona treater ionizes air, it creates a beautiful purple glow, but the side effects of the treatment process can create a nasty environment. Remember that the corona treater bombards films with ions to remove contaminants and additives from the surface while oxidizing it to increase surface energy.

While much of the material removed is immediately vaporized, there are fractionally small by-products that can build up on the ground roll and other corona-treater components. Add in heat and humidity, and the problems magnify. If routine maintenance is not performed, material on the ground roll can be a source of film wrinkling and backside treatment.

It also is worth noting that improper grounding of the corona-treater station and ground roll, as well as lack of maintenance of ground-roll bearings, can create web-path issues. If the treater roll is not properly grounded, it is possible that corona discharge is grounding to the bearings. This will “cook” the grease/oil out of the bearings and add increased resistance to the ability of the treater ground roll to turn. This allows the web to drag over the roll and induce issues such as wrinkles, film scratching, stretching, static and backside treatment. Be sure to routinely check roll bearings and add lubrication as part of your preventive maintenance plan for all rolls on the line, not just the treater rolls.

Specialty idler rolls not so idle

If you have achieved a good web path with a nice wrap around the ground roll, implemented a well-positioned nip roll, and kept up on maintenance, you should see good corona surface-treatment results. If not, there still are a few techniques to employ.

Specialized idler rolls can be used before the web gets into the treater and, in some cases, after the web exits the treater. Specialized idler rolls include bowed rollers, spreader rollers, grooved idler rolls and reverse-taper rollers.

One of the more common idler-roll styles used prior to a corona treater is a grooved idler roll. These are made from aluminum and have a series of spiral grooves cut into them. The grooves help eliminate any air from traveling under the web as it enters the corona treater.

Specialty idler rolls also can be installed as the film exits the corona treater to help prepare the web for the next step in the converting process.

To drive or not to drive the ground roll?

Drives are used when there is not enough web wrap or film tension to turn the ground roll at the required speed. Line speed, film gauge, material type, ground-roll covering, ground-roll core and the geometry of the line layout are the interrelated variables that dictate whether a drive is needed.

In some cases, the physical location of the treater requires sharper entry and exit angles than the ideal 180° film wrap around the ground roll. The film type and gauge also may prevent you from applying enough web tension to turn the roll without damaging the film.

There are three categories of drives that help control web speed and tension: tendency drive systems, speed-match drive systems and tension-control drive systems.

Tendency drives, also known as “helper drives,” help the ground roll overcome initial inertia from its mass/weight when starting a line. A tendency motor is a small, fractional-horsepower motor that is attached to a shaft on the treater roll. The “dead shaft” spins separately from the roller body. These are very common on the secondary unwind of solventless laminators and other converting applications where a nip roll is not being used and exact speed matching is not required.

If a tendency drive is not sufficient, you can use a direct drive system, which has a gearbox, gear motor and a coupler attached directly to the shaft extension on the treater. The “live” shaft is fixed to the ground roll so the roll is turned at a precise speed as designated by a signal supplied from the converting line. This type of drive system can be used in conjunction with a nip roll and has the ability to draw the web and create a tension zone.

Preventing downtime & damage from web breaks

In addition to controlling the web to ensure consistent corona treatment, web handling also is important to ensure the film does not break. Film breakage not only creates a line downtime situation, but it also can damage equipment.

Specifically on a corona treater, it is possible that the tail of a broken web can wrap around the corona-treater ground roll or electrode assembly. Damage can occur to the electrodes or insulators – and it even is possible to damage the ground roll itself.

As an added safeguard to protect your treater from these situations, you can add splice and web-break detection. These consist of sensors that send a signal to the corona treater to pivot the electrode assembly out of harm’s way when a web break or unexpected splice is detected.

Web handling & static

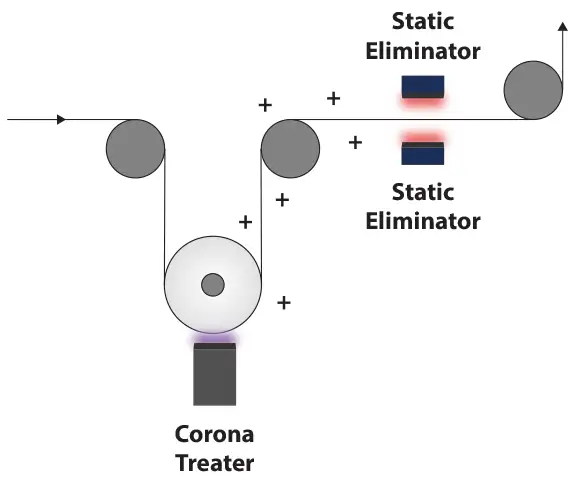

Static charges can cause sparks that shock operators, ignite flammable vapors, pinhole roll coverings, cause wrinkles in the web and even cause interference with the performance of machine-control logic. Static charges also attract contamination onto films, which interferes with adhesion and converting operations. Static charges may occur anytime two surfaces are brought into close contact and then separated. On a converting line, static charges may build up as films are unwound, pass over rollers and go through equipment such as the corona treater.

Detecting the origin of static on a line can be an elusive endeavor, but there are things you can do to eliminate or mitigate certain causes of static by following best practices. If you experience static issues around the corona treater, verify that the equipment is properly grounded. This includes checking that the station’s ground brush is in good contact with the ground roll and replacing the brush as needed. Also, as outlined earlier, ensure that all rolls are turning at the desired speed. Roll dragging or slipping will create static.

If static continues to be an issue, various portable and dedicated equipment measures static and provides insight as to where to position static-elimination devices. For best results when using static eliminators after a corona treater (see Figure 6), place a device on each side of the web. If you decide to use only one device, make sure it is directed at the treated side of the web. One other note on static and corona treating: For roll coverings that are non-conductive, it is recommended to use static brushes to remove any potential static build-up from the ground-roll covering’s surface.

Summary

The best time to prevent web-handling issues is when you are defining the application before you purchase equipment. This allows your corona-treater manufacturer and your OEM the opportunity to take into consideration the line speeds and range of films (type & gauge) you will be converting to better optimize your line for trouble-free web handling.

When experiencing problems on existing lines, verify the correct web tension for your application, ensure there is sufficient web wrap on the ground roll and maintain a record of your preventive maintenance program. If problems persist, work with your equipment suppliers and consider implementing specialty idler rolls, nip roll(s), drives packages and/or static-elimination equipment as outlined in this article.

Tom Gilbertson, vp-Application Engineering – Corona Treating Systems at Enercon Industries (Menomonee Falls, WI), has more than 35 years of technical and application experience in surface-treating technology, making him one of the industry’s leading experts. He has written and presented technical papers for TAPPI, AIMCAL, CEMA and FTA. Tom also has written numerous technical articles on all things corona treating. He can be reached at 262-250-3126, fax: 262-255-7784, email: tgilbertson@enerconmail.com, or www.enerconind.com.

Mark Plantier, vp-Marketing & Communications at Enercon Industries, holds a Marketing Management Degree from Siena College in Loudonville, NY. He serves on the company’s Senior Leadership Team. Mark has more than 30 years of experience in the packaging & converting machinery industries. He has authored and produced dozens of technical articles and educational webinars to promote best practices when using surface-treating technology. Mark can be reached at 262-250-3142, fax: 262-255-7784 or email: mplantier@enerconmail.com.